Welding joint morphology monitoring method, system and device and readable storage medium

A technology of appearance and welding parts, applied in the field of welding seam appearance monitoring methods, devices, readable storage media, and systems, can solve problems such as real-time monitoring of difficult welding processes, quality defects, and failure to find problems in time to achieve visualization , easy to observe the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

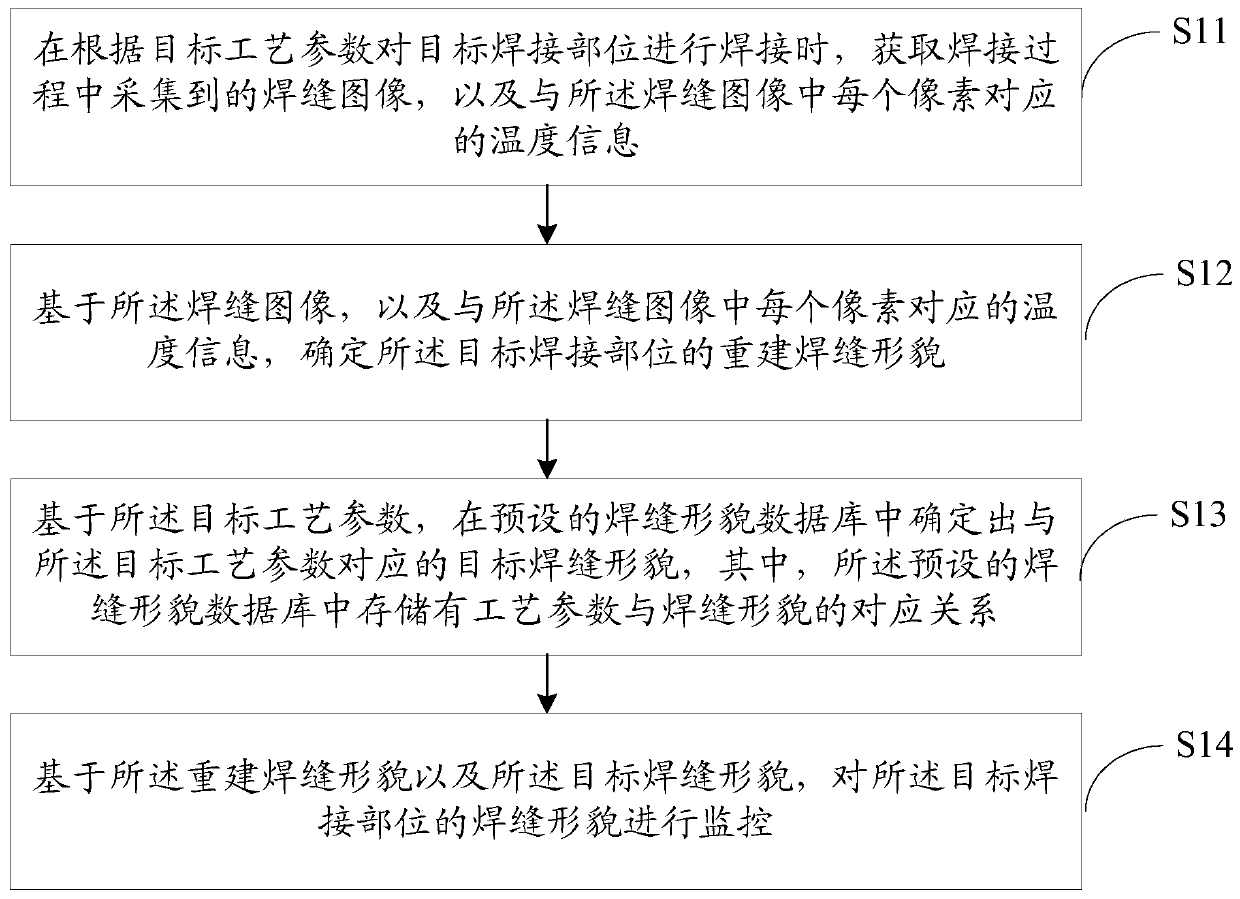

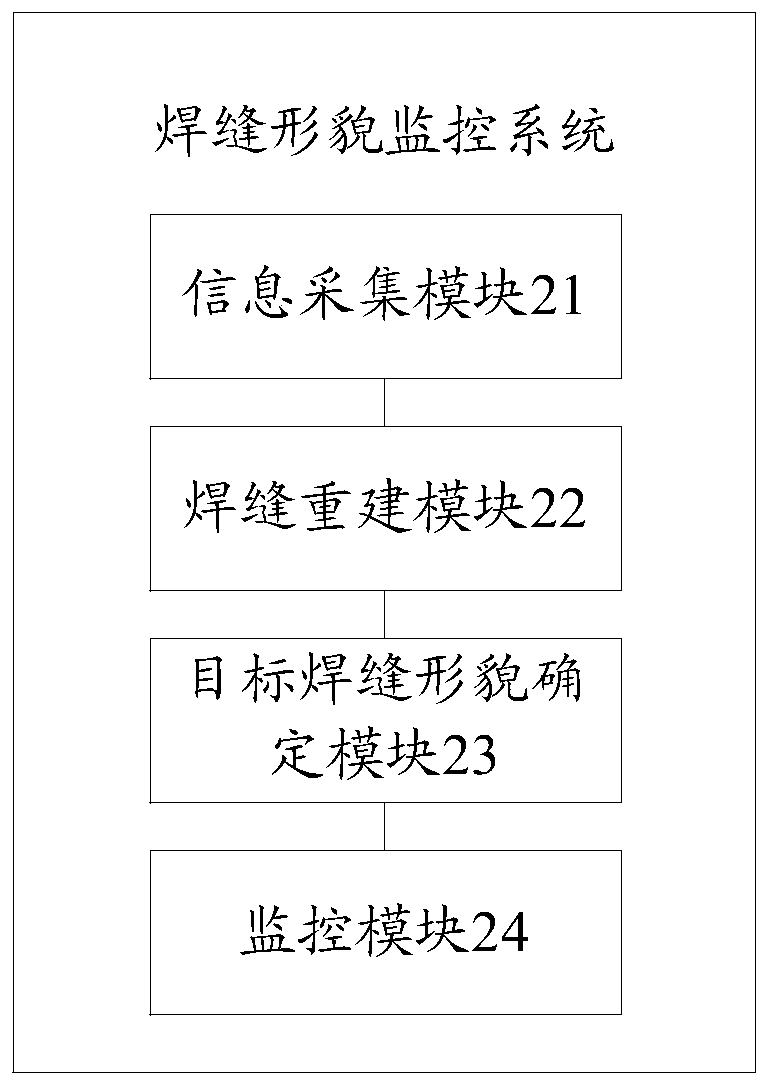

[0052] The embodiments of the present invention provide a method, system, device and readable storage medium for monitoring the appearance of the weld, which are used to monitor the appearance of the weld in real time and visualize the monitoring of the appearance of the weld. The method includes: when welding the target welding position according to the target process parameters, acquiring a weld seam image collected during the welding process, and temperature information corresponding to each pixel in the weld seam image; , and the temperature information corresponding to each pixel in the weld image, determine the reconstructed weld morphology of the target welding part; The target weld shape corresponding to the target process parameters, wherein the preset weld shape database stores the corresponding relationship between the process parameters and the weld shape; based on the reconstructed weld shape and the The target weld shape is to monitor the weld shape of the target...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com