Climate simulation device for salt spray testing machine

A technology of simulation device and salt spray experiment, applied in measurement devices, injection devices, liquid injection devices, etc., can solve the problems of difficulty in implementation, high cost, and lack of consideration of climatic factors, so as to ensure the simulation degree and reduce the structural cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

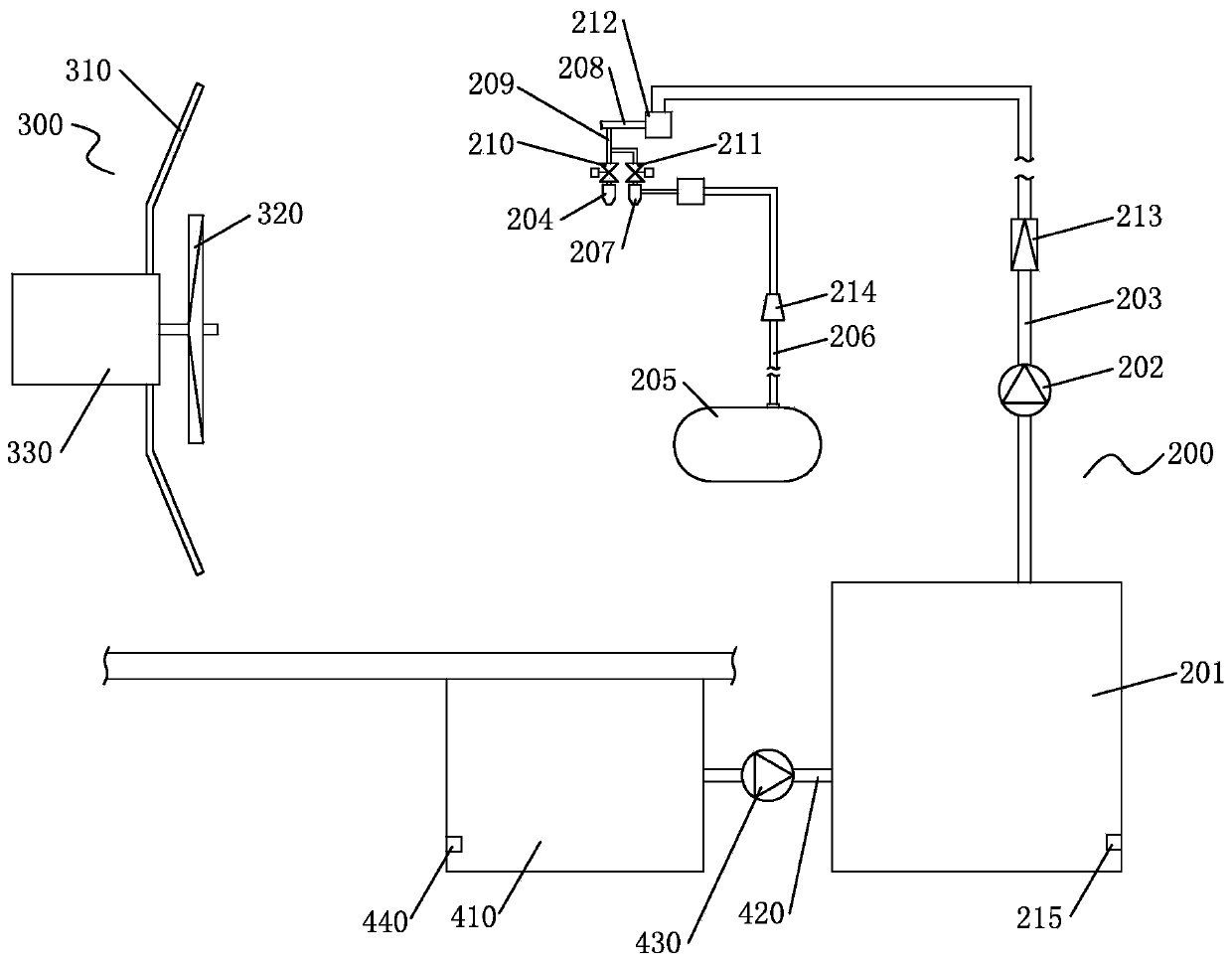

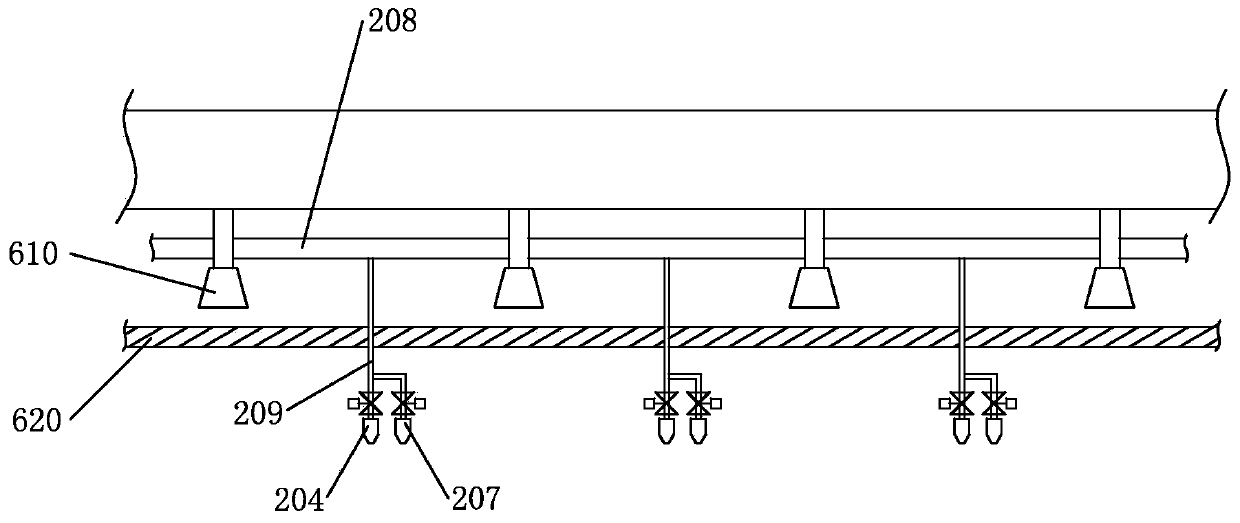

[0024] Such as Figure 1 to Figure 4 As shown, a climate simulation device for a salt spray test machine provided by Embodiment 1 of the present invention includes a control module 100 , a rain and snow module 200 and a fan module 300 . The rain and snow module 200 includes a water tank 201, a first water pump 202, a water pipe 203, a rain spray nozzle 204, an air compressor 205, an airflow pipe 206 and a snow spray nozzle 207. One end of the water pipe 203 is connected to the water tank 201, and the first water pump 202 is located at On the water pipe 203, the other end of the water pipe 203 is connected to a plurality of sub-pipes 208, and there are multiple rain spray nozzles 204 evenly distributed and connected to the sub-pipes 208 through branch pipes 209. The nozzle 207 and the rain spray nozzle 204 are connected in parallel to the branch pipe 209, and the branch pipe 209 is provided with a first water valve 210 for opening and closing the rain spray nozzle 204 and a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com