Rock tensile strength measuring device and measuring method

A tensile strength, measuring device technology, applied in the direction of measuring device, strength characteristics, using stable tension/pressure to test the strength of materials, etc., can solve problems such as affecting test accuracy, complex test technology, time-consuming and laborious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

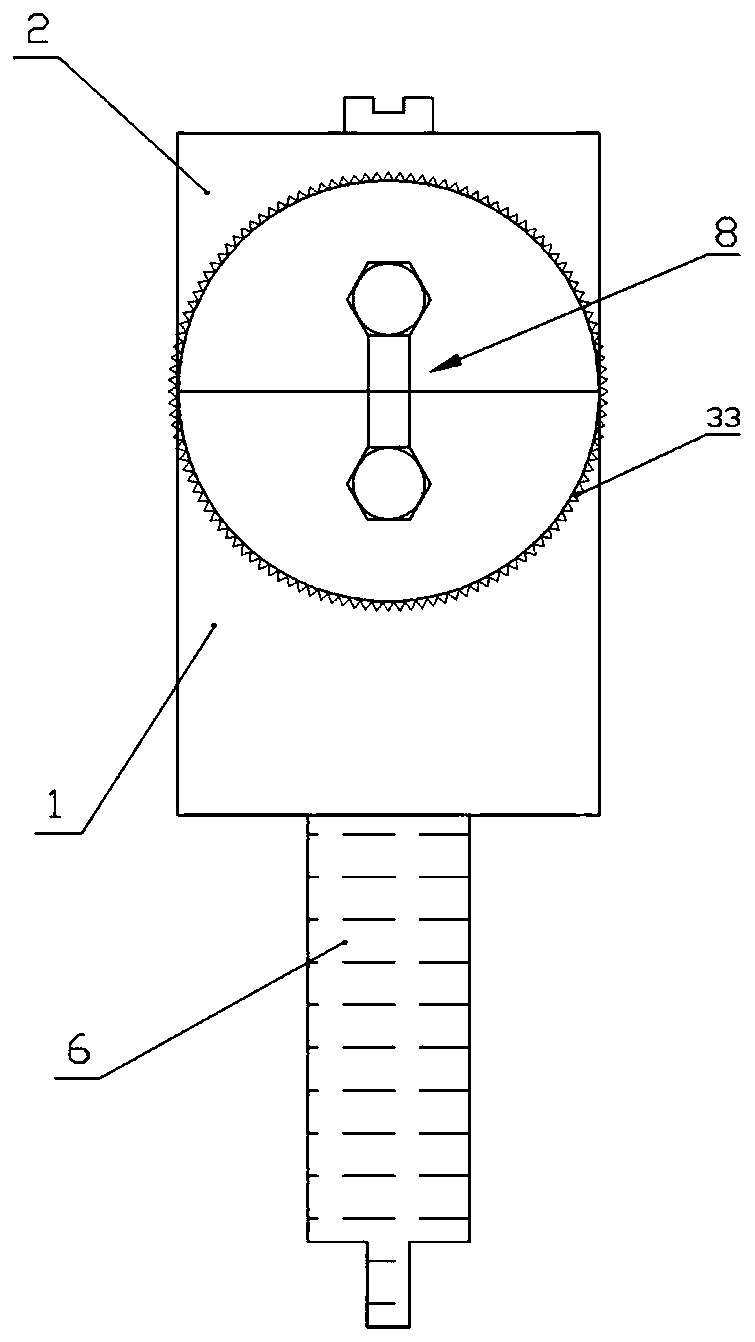

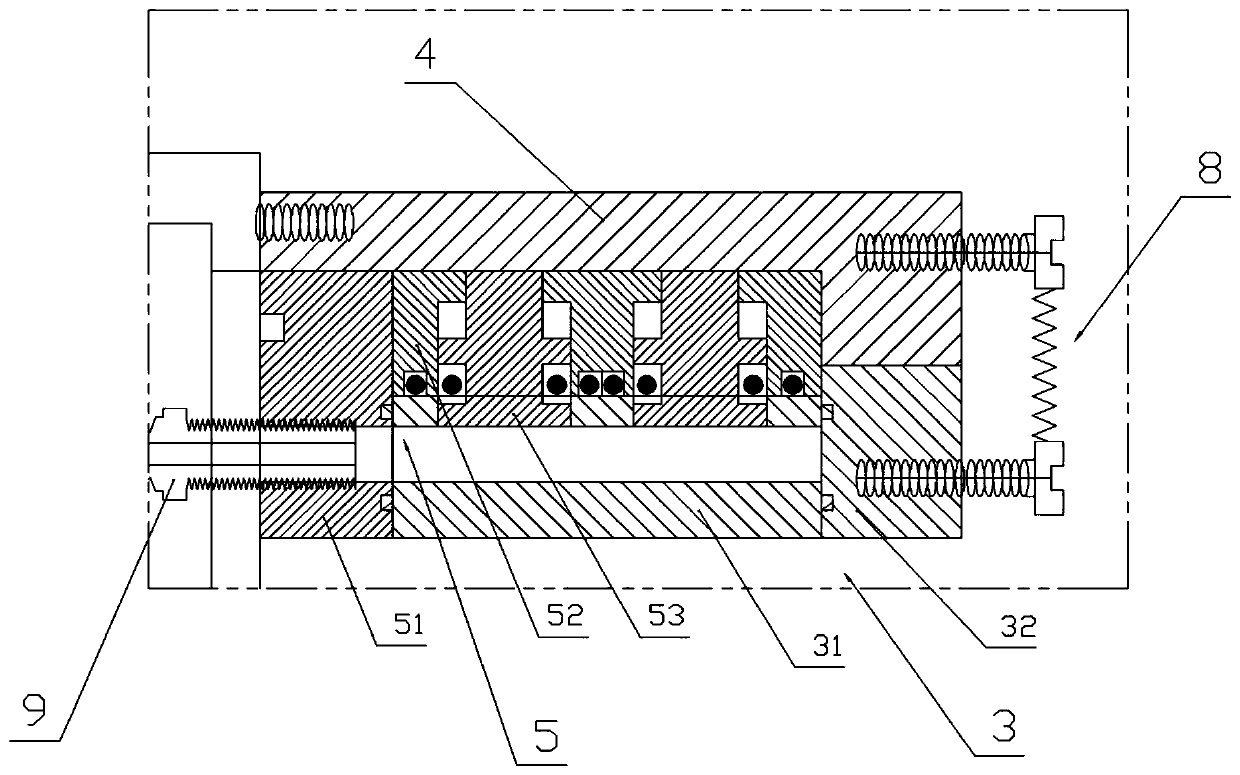

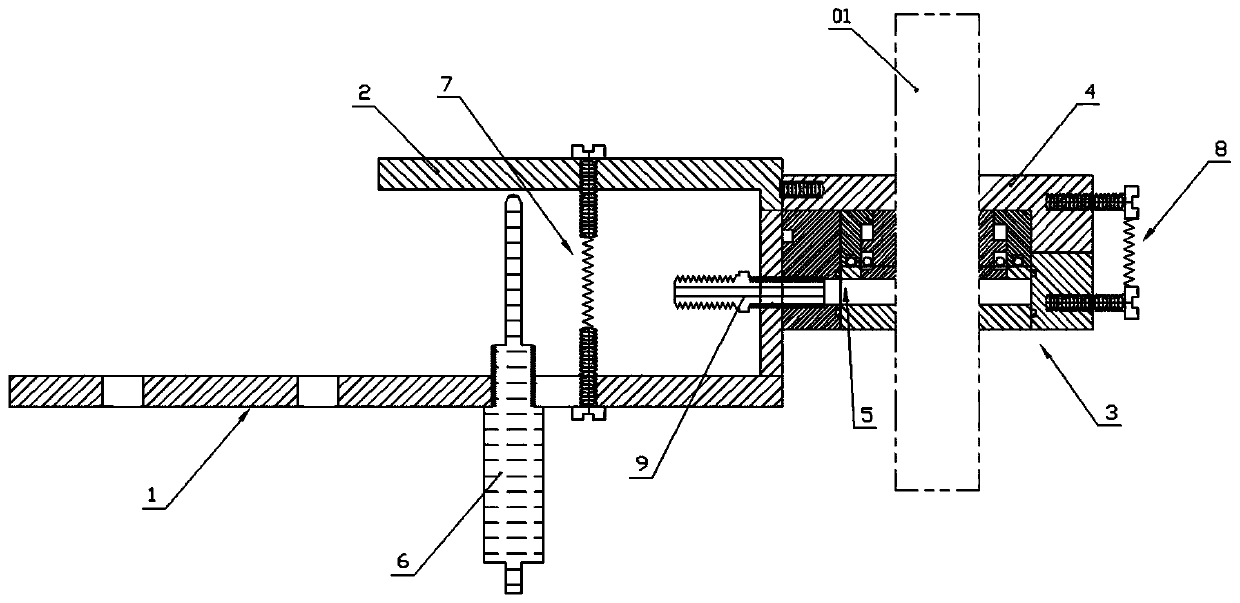

[0047] Such as figure 1 , figure 2 As shown, the rock tensile strength measuring device disclosed in this embodiment includes a lower seat 1, an upper seat 2, a lower pressure block 3, an upper pressure block 4, a force applying mechanism 5, a displacement sensor 6, a vertical Tension reset mechanism 7 and transverse tension reset mechanism 8.

[0048] Both the lower seat 1 and the upper seat 2 are L-shaped seat bodies. Both the horizontal section and the middle part of the vertical section of the lower seat 1 are provided with through holes, and the upper seat is buckled upside down on the lower seat and tensioned by the vertical tension reset mechanism 7, which includes a pair of tension bolts 71 With the tension spring 72, two tension bolts are arranged vertically relative to each other, the tension bolt on the top is threaded on the upper seat 2, the tension bolt on the bottom is threaded on the lower seat, and the tension spring is connected to the two tension bolts. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com