Low pressure electrode boiler

A low-voltage electrode and boiler technology, which is applied in the field of low-voltage electrode boilers and boiler manufacturing, can solve the problems that large-capacity electrode boilers are difficult to adapt to high-frequency and low-consumption use, and achieve faster gas outlet speed, smaller water volume, and faster start-up speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The low-voltage electrode boiler of the present invention can be made of the following materials, but not limited to, such as: pressure-resistant steel, stainless steel, insulators, valves, pipes, etc.

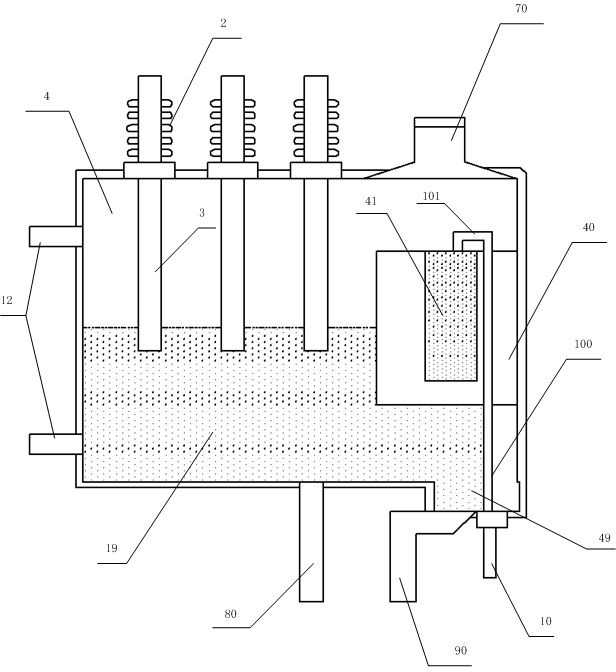

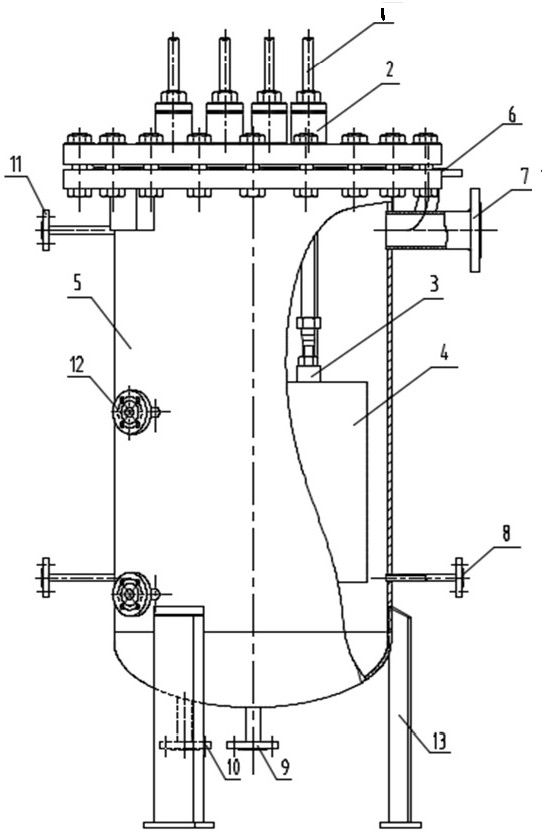

[0025] Such as figure 1 Shown is the side structural view of the low-voltage electrode boiler of the embodiment of the present invention; And refer to figure 2 .

[0026] The low-voltage electrode boiler of the embodiment of the present invention comprises: electrode rod 1, furnace body 5, floating water tank 40 and liner 4; Floating on the water 19 in the liner.

[0027] Described liner 4 is fixed in described furnace body 5, and described electrode bar 1 has electrode 3; Described electrode 3 is fixed on the top of described liner 4 and is inserted in described liner 4; Generally be three electrodes 3, the distance between each electrode 3 and the bottom of the liner 4 is the same.

[0028] Normally, the electrode rod 1 also includes an insulator 2 ; the insulato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com