Pneumatic hydraulic corrugated pipe annular combination type wear-resisting ball valve

A pneumatic hydraulic, bellows technology, applied in valve details, valve devices, engine components, etc., can solve problems such as frequent operating failures, excessive leakage, and strain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

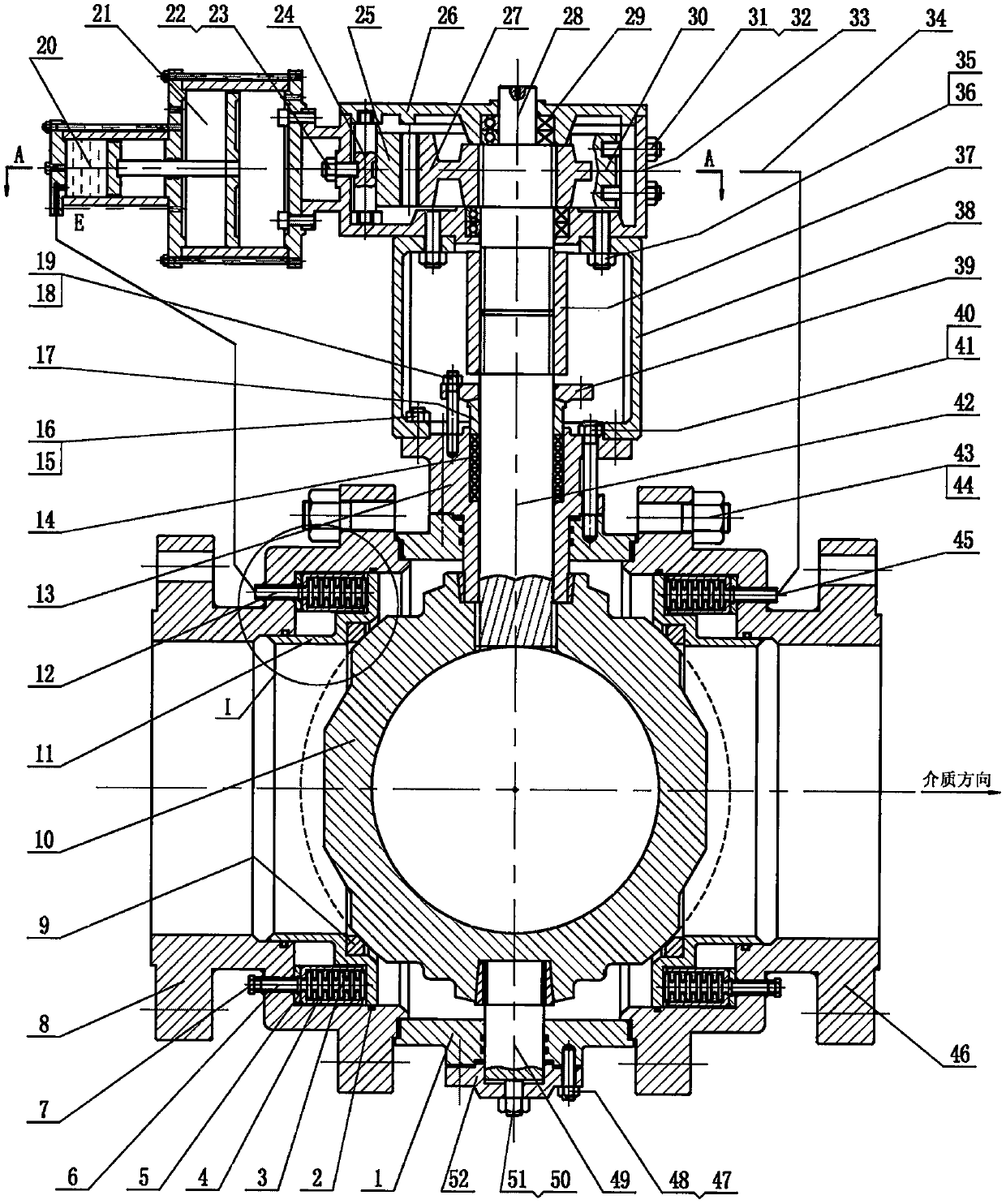

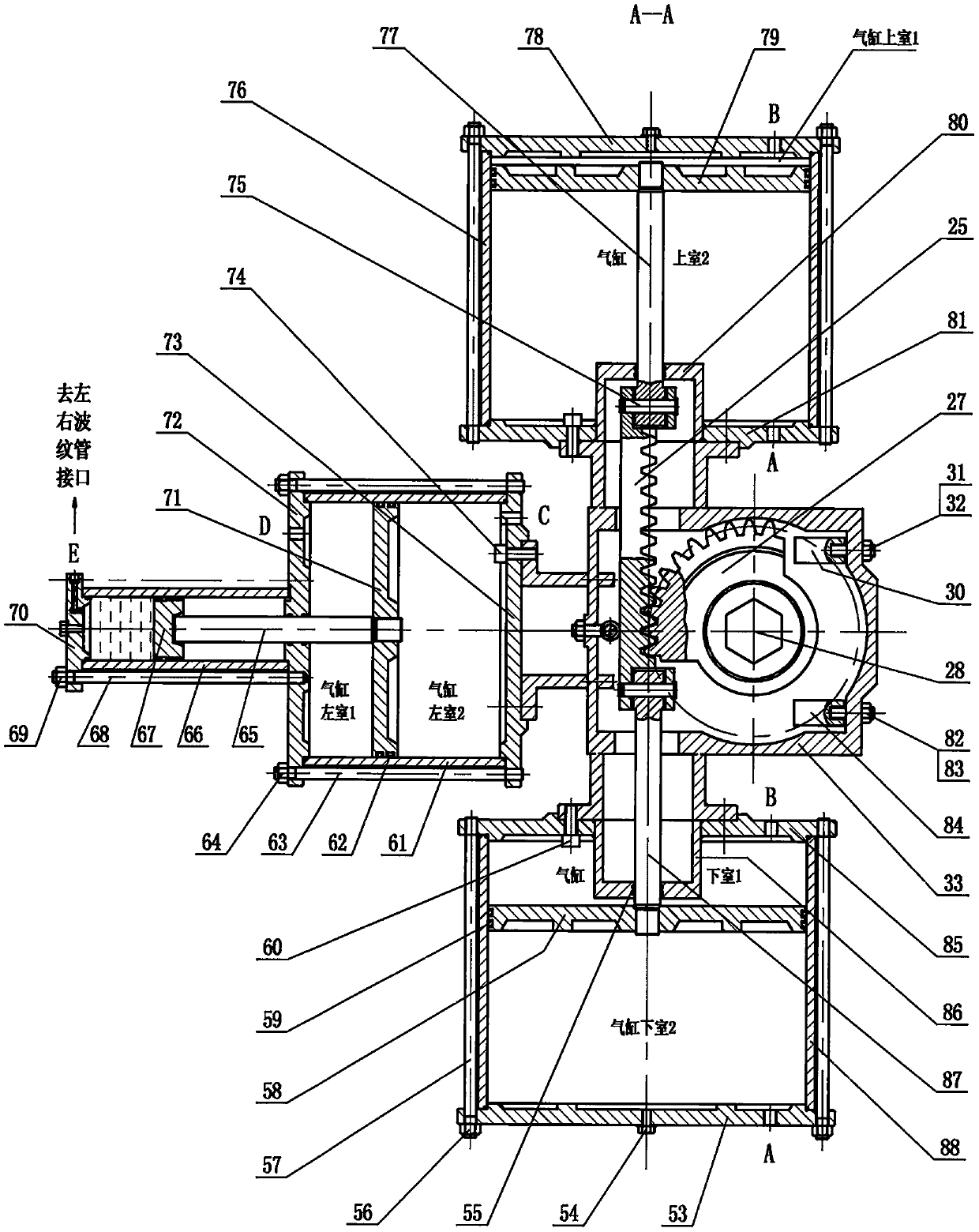

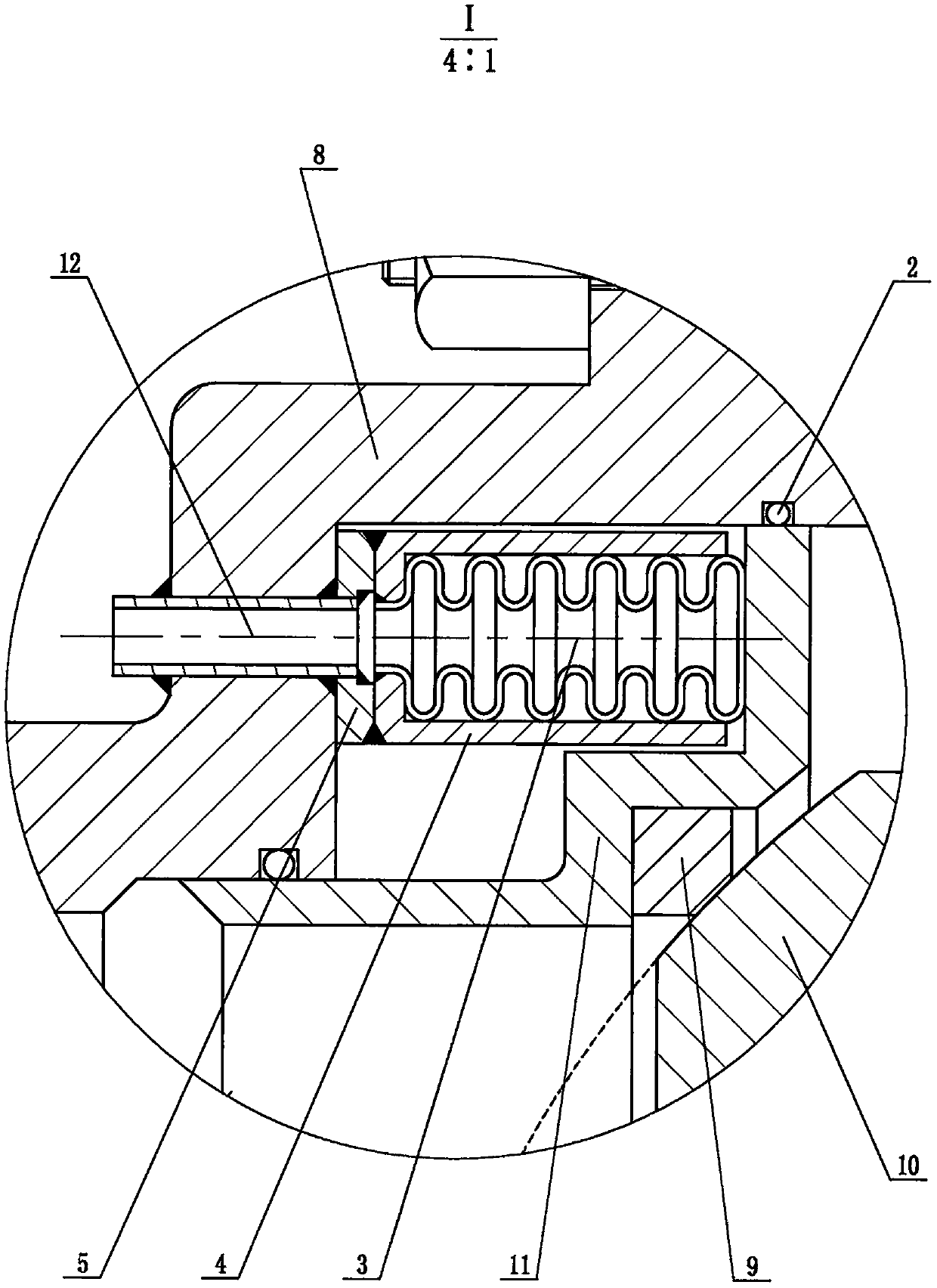

[0017] The working principles of the embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0018] 1. When the valve is closed:

[0019] The power-off signal sent from the control room de-energizes the solenoid valve F1, the solenoid valve F1 switches to the air port 4 with air pressure output, and the air control valve F2 acts, and then the air port 4 has air pressure output, the air pressure is divided into two ways: one way Supply air to the A port of the upper and lower cylinders, and the other to supply air to the air port 1 of the shaft control valve F3 (the valve is temporarily inactive and has no air pressure output). At this time, the air pressure supplied by the A port of the cylinder enters the upper chamber 2 and the lower chamber 2 of the cylinder. Then the upper and lower pistons 79, 58 are pressed and pushed upwards, and the upper and lower piston rods 77, 84 also move upwards together, and the push-pull rac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com