Gas silencing and guiding device for mining local ventilator

A diversion device and ventilator technology, which is applied to components of pumping devices for elastic fluids, ventilation of mines/tunnels, mining equipment, etc., and can solve problems such as noise pollution, excessive noise, unsafe accidents, etc. , to achieve the effect of reducing airflow noise, reducing airflow noise, and ensuring ventilation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

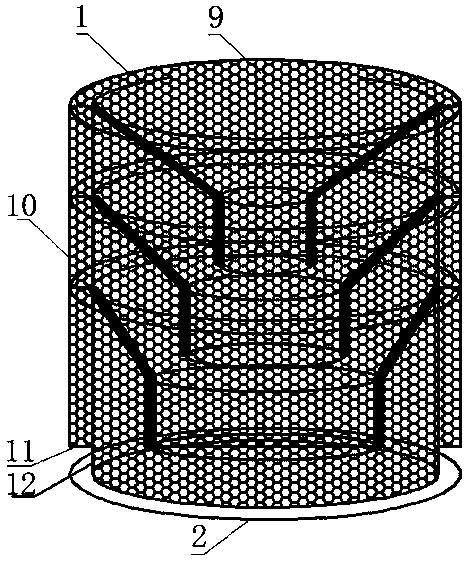

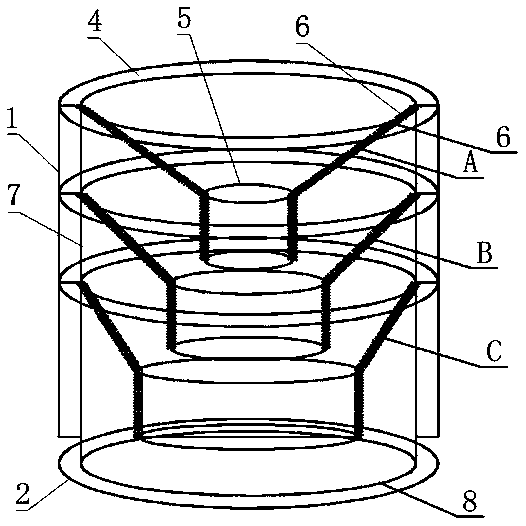

[0016] like Figure 1-3 As shown, the present invention includes a multi-stage diversion muffler cone, a positioning bracket assembly, a protective cover 1 and a connecting flange 2. The multi-stage diversion muffler cone is stacked up and down and distributed in gaps, and each stage includes a The diversion cone 3 of the inverted cone structure, the upper edge of the diversion cone 3 extends outwards in parallel to form a ring-shaped support platform 4, the tip of the diversion cone 3 is provided with an opening, and a diversion tube 5 is connected to the opening; each The opening of the diversion cone 3 of the first-stage diversion muffler cone is gradually reduced, and the diameter of the diversion cylinder 5 is gradually increased;

[0017] like figure 2 As shown, the positioning bracket assembly includes a plurality of support rods 7 and connecting rings 8, the support rods 7 are arranged between the support platforms 4 of the flow diversion and muffler cones of each st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com