Self-oscillation coal powder filtering system used in process of coalbed methane mining

A mining process, self-excited oscillation technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems that affect the efficiency and performance of coalbed methane mining, coal dust deposition, pump stuck, etc., to prevent The effects of clogging the filter, increasing the flow rate, and improving the extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are enumerated hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

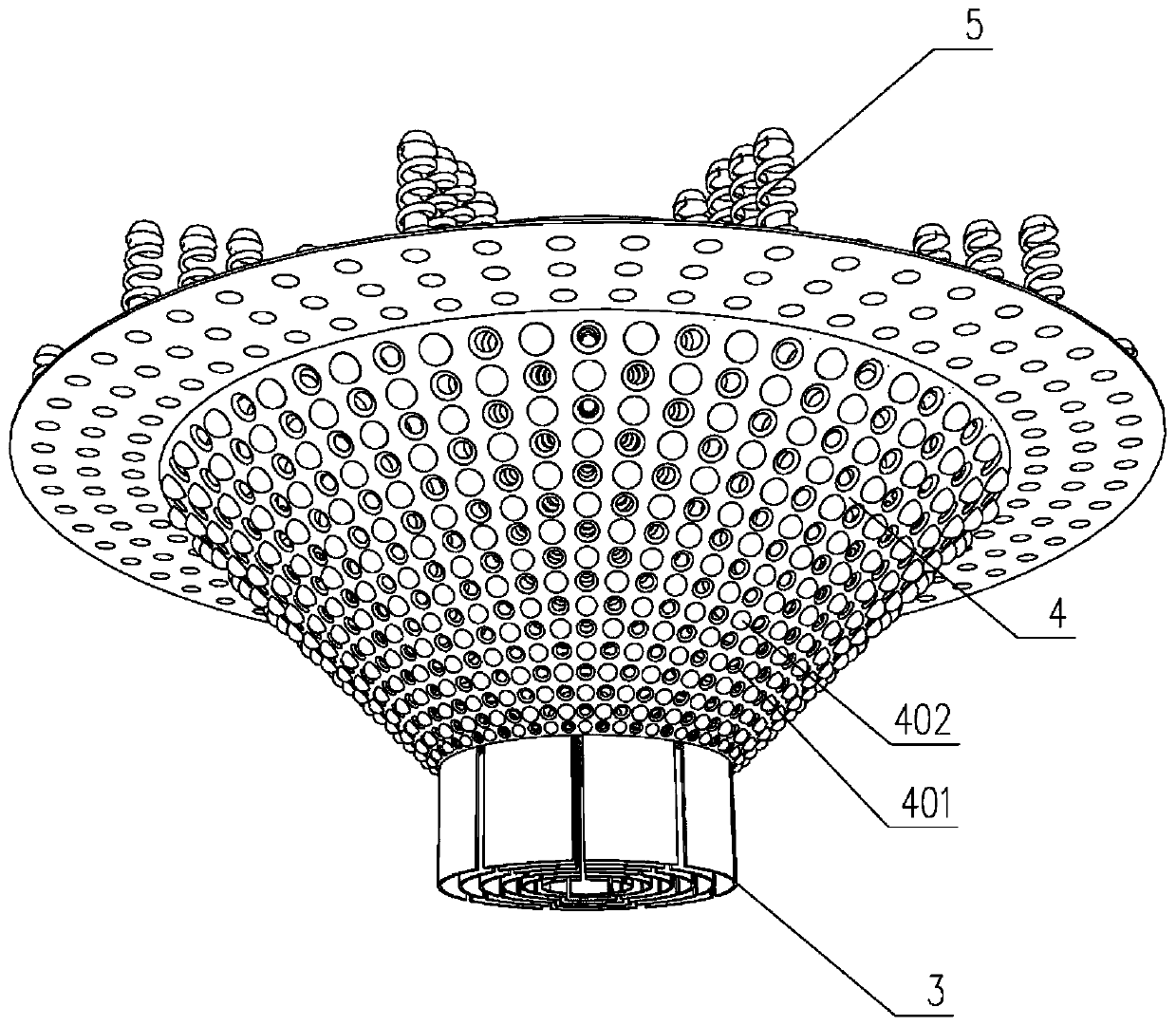

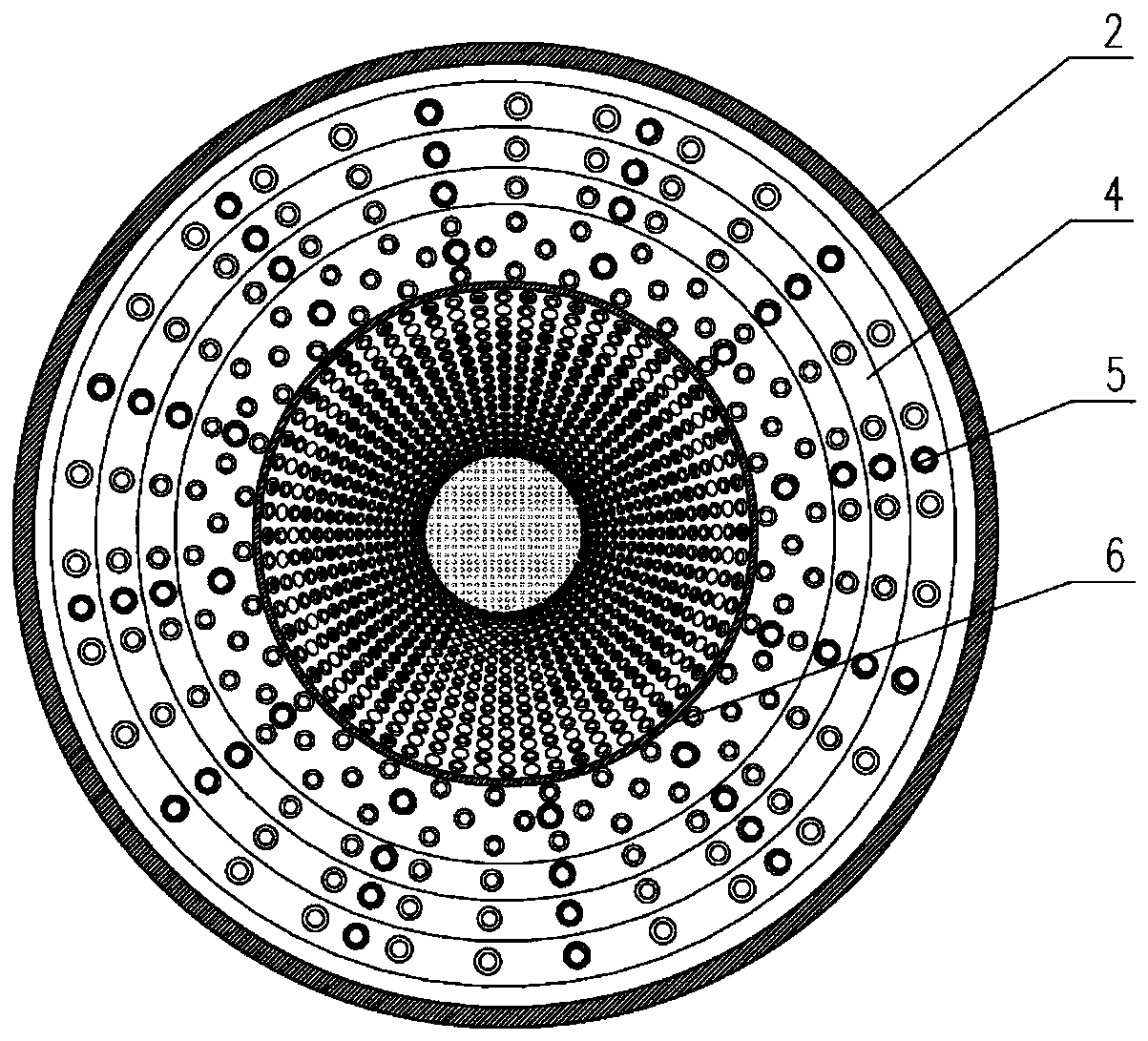

[0027] See Figure 1 to Figure 5 , a self-excited oscillating pulverized coal filter system used in the mining process of coalbed methane, the system includes: an outer cylinder seat 2, an end cover 11, a spring assembly 5, a filter assembly 4, an oscillating plate 3, an inlet pipe 1, an outlet Water pipe 9 and sand pump 10; the outer cylinder seat 2 is a cylindrical body with a cavity inside, and a hole is opened in the center of the bottom; the upper nozzle of the water inlet pipe 1 is upward from the opening at the bottom of the outer cylinder seat 2 Extending into the inner cavity of the outer cylinder seat 2; the lower nozzle of the water inlet pipe 1 is connected downwards with the coalbed methane production well; the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com