Reuse method of abandoned coalbed methane wells in goaf

A technology for coalbed methane wells and goafs, which is applied in drilling equipment and methods, mining fluids, mining equipment, etc., to achieve the effect of ensuring safe and efficient mining of coal mines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] After the coal seam is mined, a goaf is formed. The pre-drainage gas well above the goaf is initially considered to be transformed into a goaf well, that is, negative pressure drainage is used on the ground to reduce the methane concentration in the goaf. In the later stage, with the extension of the extraction time, the gas concentration in the goaf decreased rapidly. In order to ensure the full utilization of the well, further reconstruction is required.

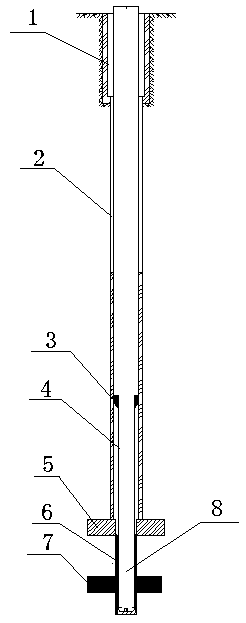

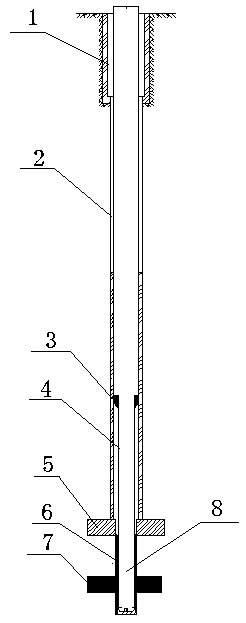

[0010] The structure of the abandoned well in the goaf area includes the first hole 1 of the abandoned well in the goaf area, the diameter of the borehole is 311.15 mm, the diameter of the casing is 244.8 mm, and the cement is returned to the ground; the second hole 2 of the abandoned well in the goaf area is 215.9 mm in diameter. mm, the diameter of the casing is 139.7mm, and the cement return height is 200m to the roof of the goaf.

[0011] The method for reusing abandoned coalbed methane wells in the goaf, the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com