Water-cooled iron storage type iron runner and cooling method thereof

A technology of water cooling and iron channel, which is applied in the direction of discharge device, inspection device, etc., can solve the problems of short service life, environmental pollution, high labor intensity, etc., and achieve the effect of increasing service life, improving working environment and preventing iron leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

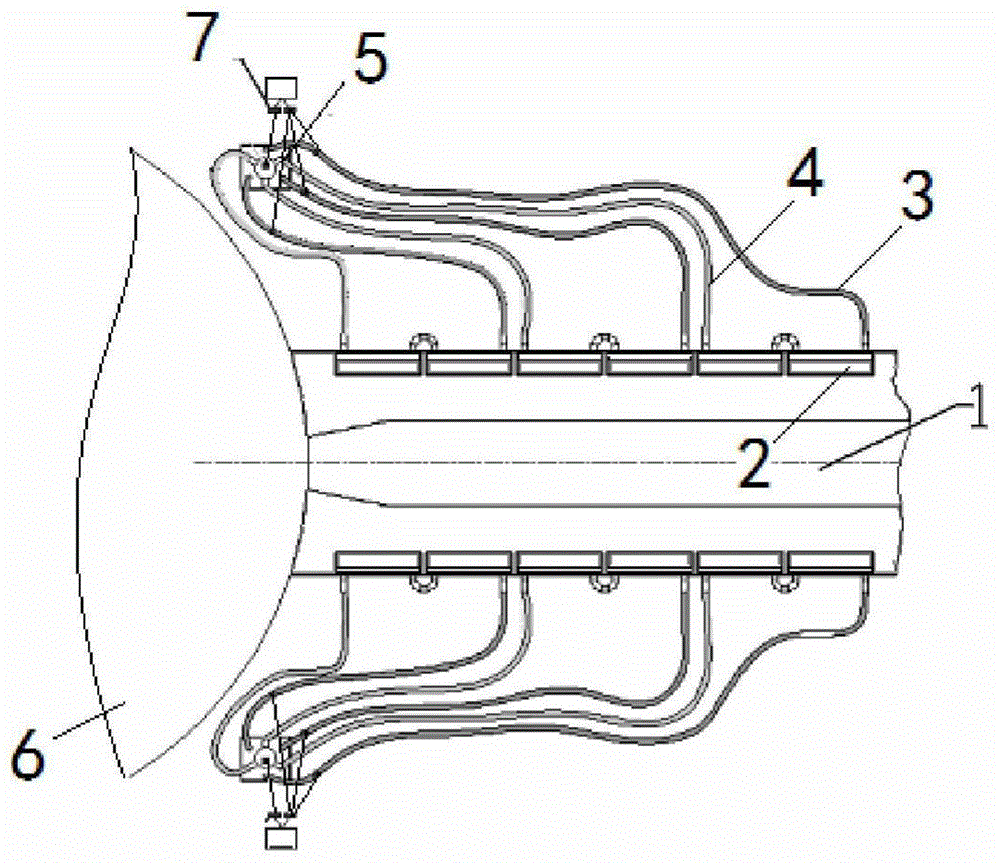

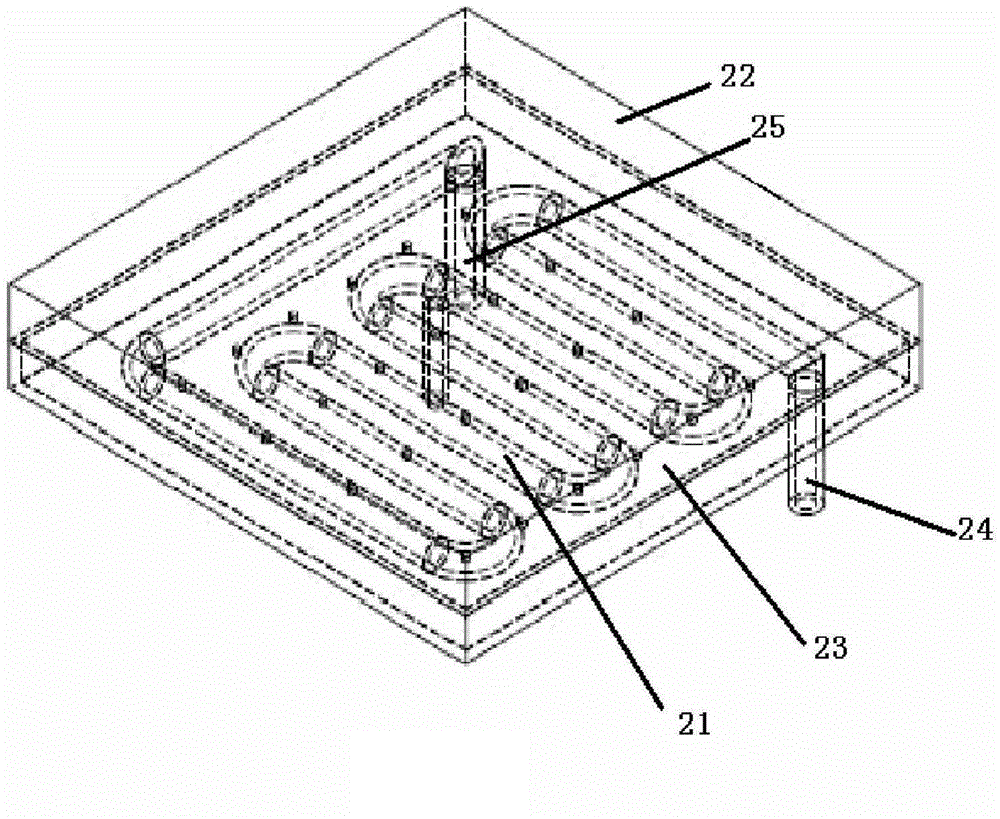

[0023] Example 1: Such as figure 1 , figure 2 , image 3 As shown, a water-cooled iron-storage iron trench includes an iron-storage iron trench 1, a water-cooled assembly 2 and a temperature measuring and monitoring device 7. The iron-storage iron trench 1 is connected to a blast furnace 6; the left side structure of the iron trench is a water-cooled assembly 2. It is placed on the inside of the side wall of the front half of the trench 1 and is in direct contact with the lining castable; the water inlet pipe 3 and the water outlet pipe 4 of the circulating water circuit are connected to the water cooling assembly 2; the circulating water collection bucket 5 is connected to the water inlet pipe 3 and the water outlet pipe 4 and temperature measurement and monitoring device 7; a plurality of water-cooled components 2 form a continuous row, and the continuous row is placed on the inner side of the side wall of the front half of the trench 1;

[0024] The structure on the right sid...

Embodiment 2

[0029] Example 2: Such as figure 1 , figure 2 , image 3 As shown, a water-cooled iron storage type iron trench, in another embodiment of the present invention, the structure of the water-cooled iron storage type iron trench is the same as the first embodiment. The cermet pouring body of the water-cooled component is formed by pouring refractory material, which contains 10% by weight of metal fiber and 90% by weight of refractory. The water-cooling component is a rectangular block with a thickness of 100mm, a width of 2000mm, and a height of 500mm, covering the entire length of the sidewall of the iron trench to achieve full-length water cooling of the main trench. The water paths between the water cooling components are connected in parallel.

Embodiment 3

[0030] Example 3: Such as figure 1 , figure 2 , image 3 As shown, a water-cooled iron storage type iron trench includes an iron storage type iron trench, a water-cooled component, a circulating water circuit and a temperature measurement monitoring system; the water-cooled component is placed on the inside of the side wall of the front half of the iron trench, and is lined with castable Direct contact; the cooling water is introduced from the blast furnace cooling water system to the water-cooled component to cool the lining of the iron trench side wall, and the cooling water flowing out of the water-cooled component flows to the circulating water collection bucket of the blast furnace platform to form a circulating water path; monitored by the temperature monitoring system The temperature of the inlet and outlet water of the water-cooled component.

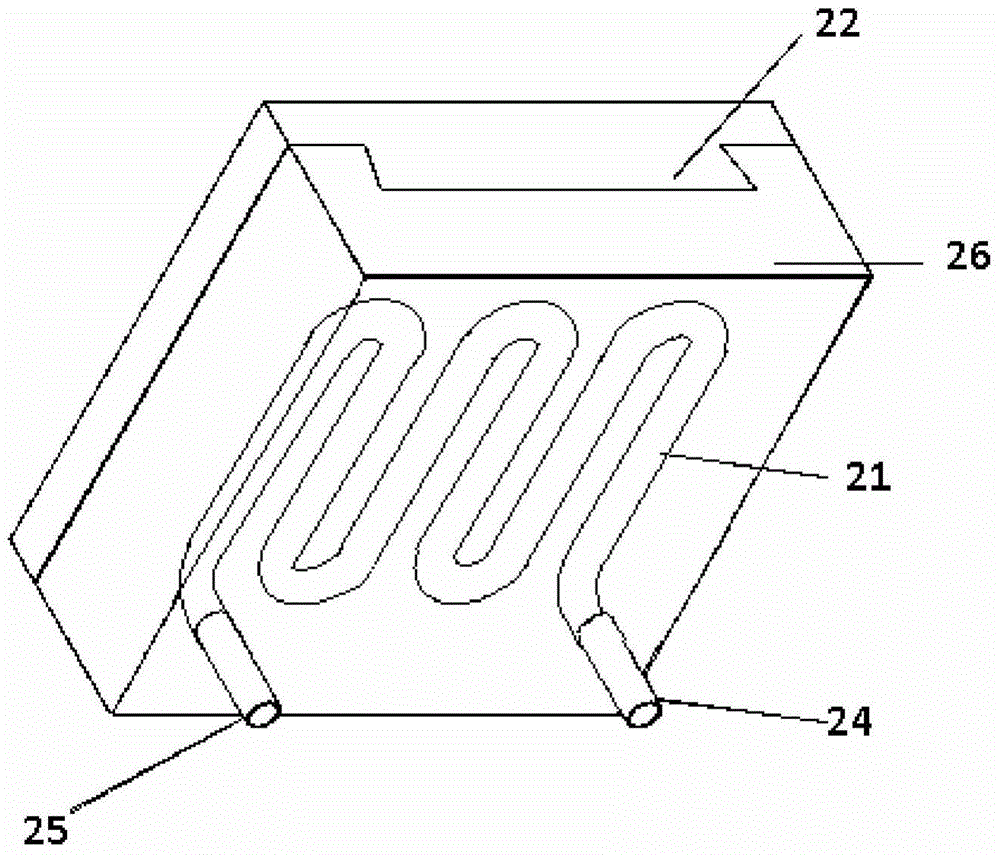

[0031] The water cooling component includes a water pipe, a cermet pouring body and a metal back plate. The water pipe is laid o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com