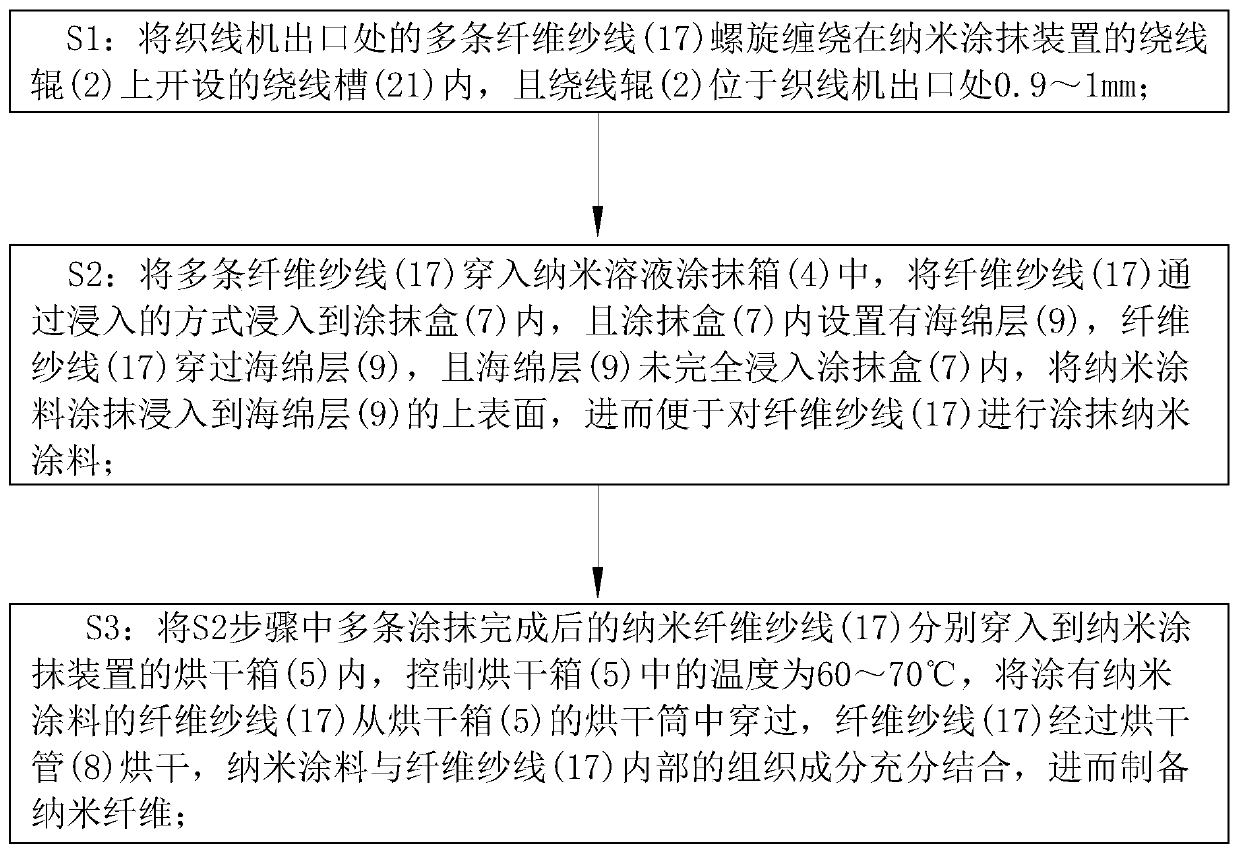

Nano-fiber manufacturing apparatus and method

A nanofiber and manufacturing equipment technology, applied in the field of nanofiber manufacturing equipment, can solve the problems of low nanofiber production efficiency, unstable production equipment, poor production quality, etc., and achieve the effect of increasing efficient coating operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

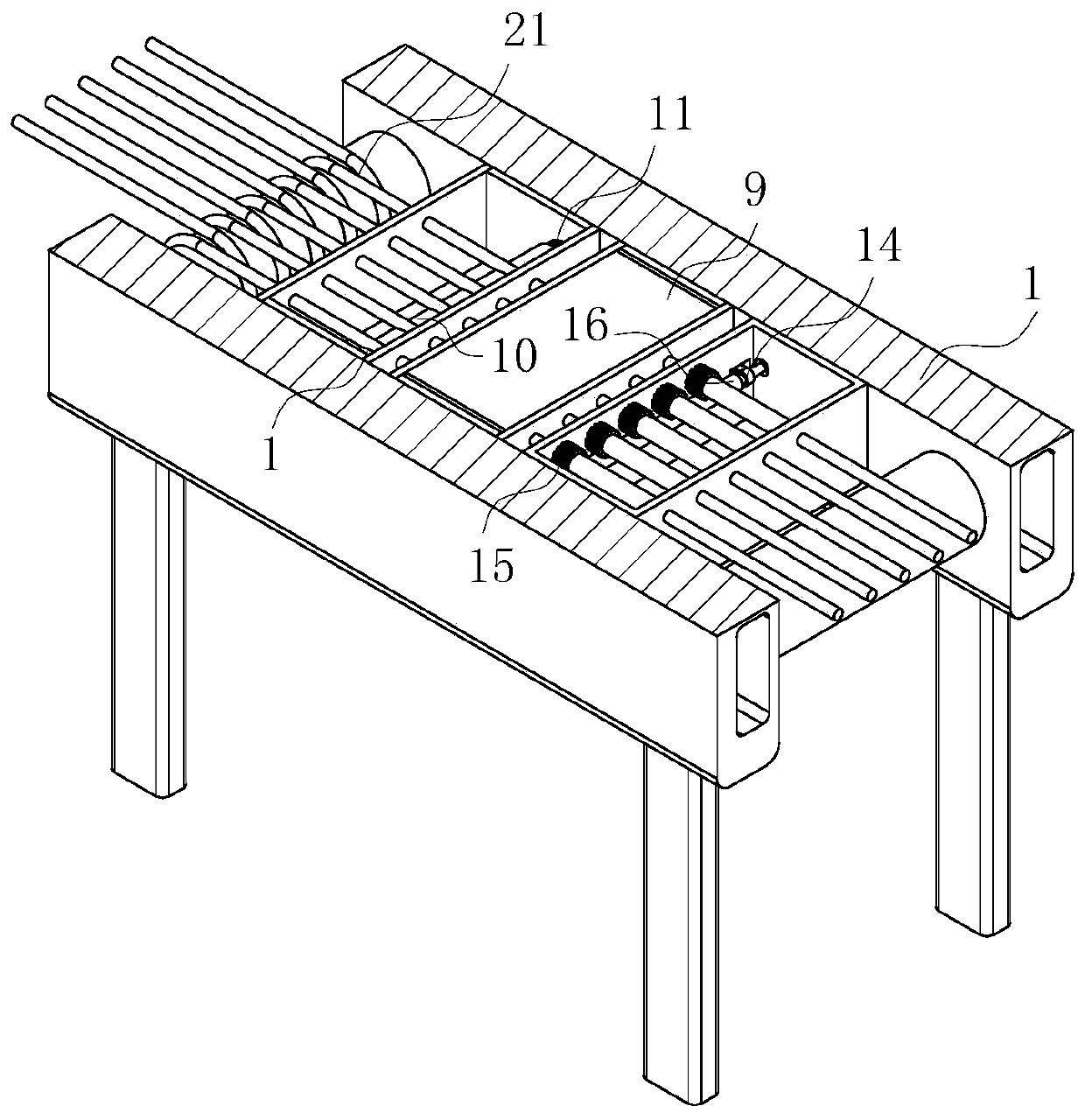

[0031] As an embodiment of the present invention, the end of the rubber rotating roller 10 is provided with a driving gear 11, and the driving gear 11 is meshed with a driven gear 12; the driven gear 12 is installed in the preheating box through a rotating column 3; the rotating column is sleeved with a transmission belt 14; a plurality of the drying pipes 8 are installed in the drying box 5, and the ends of the drying pipes 8 are equipped with rotating worm gears 15; In the dry box 5, a rotating worm 16 is installed through the rotation of the rotating column, and the end of the rotating worm 16 is sleeved with a transmission belt 14; the rotating worm 16 and a plurality of rotating worm wheels 15 are mutually rotating and meshed; 10 When rotating under the frictional force of the fiber yarn 17, the rotation of the rubber rotating roller 10 will drive the driving gear 11 to rotate, and then the driven gear 12 will drive the transmission belt 14 socketed on the rotating column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com