Electroplate liquid and method for electroplating steel shell through electroplate liquid

A technology of electroplating solution and steel shell, which is applied in the field of electrochemistry and can solve problems such as gas swelling, precipitation, and gas leakage

Active Publication Date: 2020-05-15

FUJIAN NANPING NANFU BATTERY

View PDF2 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in the subsequent electroplating process, since the steel case of the battery is a deep-hole device, the nickel plating layer inside the steel case is unevenly plated, which leads to the precipitation of iron ions in the steel case into the electrolyte. Galvanic cells are formed inside the battery, causing bloating and gas leakage

However, the nickel-plated cold-rolled thin punched steel case is expensive, and the nickel coating may be torn during the punching process, resulting in iron ions in the steel case being precipitated into the electrolyte, and stored in the battery for a long time. Forming a primary battery, causing inflation and gas leakage, affecting the electrical performance of the battery, and even more serious damage to electrical appliances

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0037] The present invention will be described below with reference to specific embodiments. It should be noted that these embodiments are only illustrative and do not limit the present invention in any way.

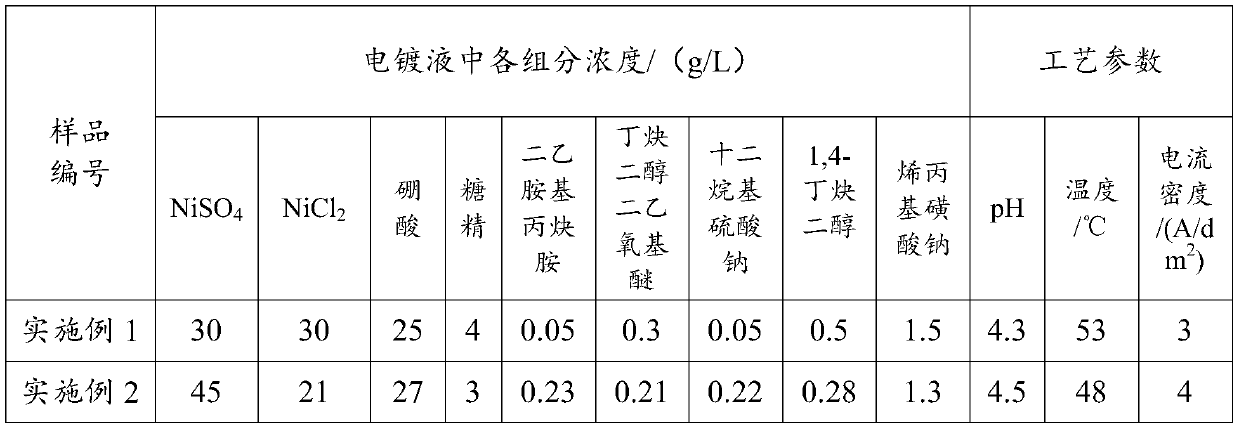

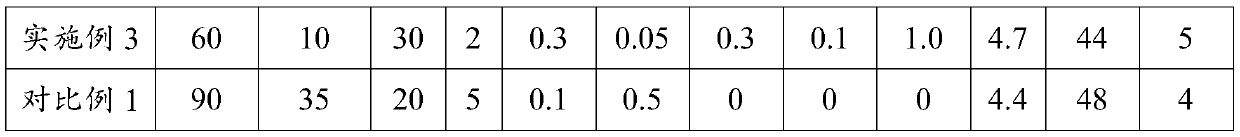

[0038] The electroplating solution composition of each sample of table 1 and the technological parameters used during electroplating

[0039]

[0040]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

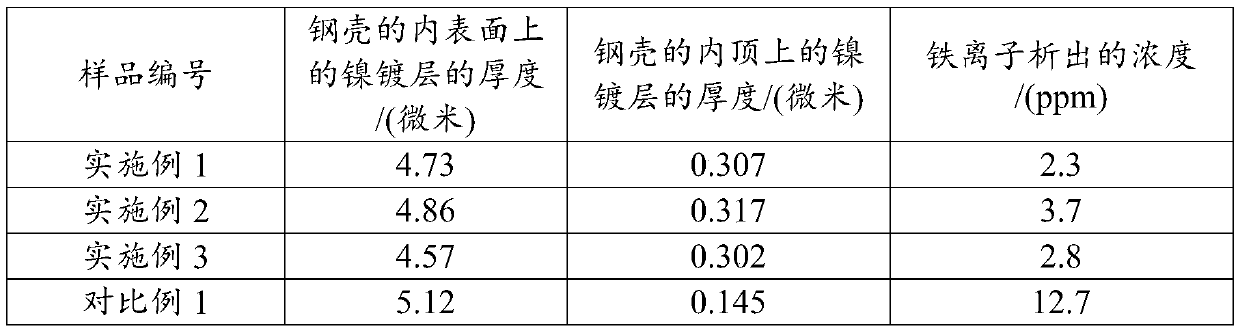

The invention discloses electroplate liquid and a method for electroplating a steel shell through the electroplate liquid. Water serves as a solvent of the electroplate liquid. In the electroplate liquid, the concentration of NiSO4 ranges from 30 g / L to 60 g / L, the concentration of NiCl2 ranges from 10 g / L to 30 g / L, the concentration of lauryl sodium sulfate ranges from 0.05 g / L to 0.3 g / L, the concentration of an alkyne compound ranges from 0.1 g / L to 0.5 g / L, and the concentration of sodium allysulfonate ranges from 1.0 g / L to 1.5 g / L. A more compact and evenly-electroplated nickel-plated layer can be obtained on the inner surface of the steel shell through the synergistic effect of components in the electroplate liquid, the precipitation concentration of iron ions in the steel shell isbelow 5 ppm, the thickness of the nickel-plated layer on the inner surface of the steel shell is not smaller than 0.5 micrometer, the thickness of a nickel-plated layer at the inner top of the steelshell ranges from 0.2 micrometer to 0.4 micrometer, and therefore the problem that air expansion and liquid leaking are caused after primary batteries are formed in batteries after batteries are stored for a long time is reduced, and the electric performance of batteries is improved.

Description

technical field [0001] The invention belongs to the field of electrochemistry, in particular, the invention relates to an electroplating solution and a method for electroplating a steel shell by using the electroplating solution. Background technique [0002] Generally speaking, an alkaline battery is composed of a steel shell, a cathode, an anode, a diaphragm, and an electrolyte. Among them, the steel shell is one of the most important parts of the alkaline manganese battery, which plays the dual role of the active material storage container and the positive electrode collector in the battery. As an active material container, it must have sufficient mechanical strength, occupy as little space as possible in the battery, and be able to withstand the corrosion of chemical substances inside the battery; as a positive electrode collector, it must have as high a conductivity as possible, and The best possible electrical contact with the positive active material is possible. Th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C25D3/16C25D7/00C25D5/04

CPCC25D3/16C25D5/04C25D7/00

Inventor 常海涛涂志晖林建兴王贵希薛祥峰刘国镇

Owner FUJIAN NANPING NANFU BATTERY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com