Fluorinated styrene/butadiene copolymer and preparation method thereof

A fluorinated styrene and butadiene technology, applied in the direction of rolling resistance optimization, road transportation emission reduction, etc., can solve the problems of affecting tire performance, poor dispersion, lack and other problems, and achieve the effect of improving performance and improving poor dispersion.

Active Publication Date: 2022-06-03

PETROCHINA CO LTD

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the lack of functional functional groups in the existing styrene-butadiene rubber, when subsequently processed with carbon black and silica, the dispersion of carbon black and silica is poor, which affects the performance of the tire

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0026]

[0028] At room temperature, under the protection of an inert gas, 10.1 mg of rare earth organic compound 1 and 18.4 mg [Ph

Embodiment 2

[0033]

[0035] At room temperature, under the protection of an inert gas, 10.1 mg of rare earth organic compound 1 and 18.4 mg [Ph

Embodiment 3

[0040]

[0042] At room temperature, under the protection of an inert gas, 10.1 mg of rare earth organic compound 1 and 8.4 mg [Et

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

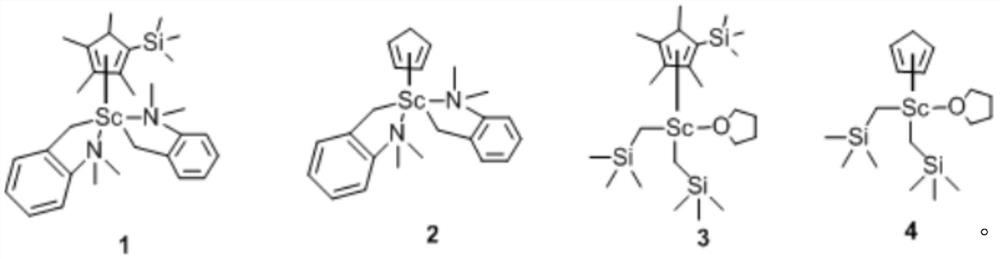

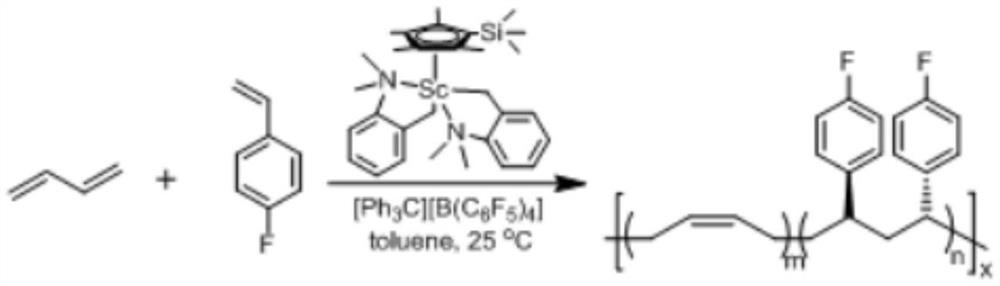

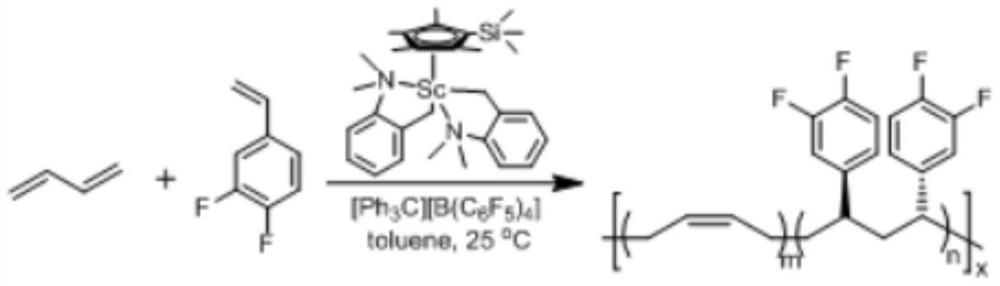

The invention discloses a fluorinated styrene / butadiene copolymer and a preparation method thereof. The fluorinated styrene and butadiene copolymer is characterized in that: based on 100% of the total amount of the obtained copolymer, each The proportions of the components are as follows, the content of fluorostyrene in mass percent is 1% to 30%, and the content of butadiene in mass percent is 70% to 99%; the structure of butadiene in the polymer is 1,4-structure and 3, There are two forms of 4-structure, the content of 1,4-structure polybutadiene is 45%-98%, and the content of cis-1,4-polybutadiene is 30%-97%. The catalytic system of the preparation method uses a rare earth Sc compound as a catalyst, and a boron reagent as a cocatalyst, and the two together constitute a catalytic system for preparing fluorostyrene and butadiene copolymers. Under this catalytic system, fluorostyrene and butadiene Diene is polymerized to produce a copolymer of fluorostyrene and butadiene.

Description

Fluorinated styrene / butadiene copolymer and preparation method thereof technical field The invention belongs to the field of styrene-butadiene rubber, specifically relate to a class of fluorostyrene / butadiene copolymer and preparation thereof preparation method. Background technique Styrene-butadiene rubber based on styrene and butadiene has the advantages of wear resistance, aging resistance, heat resistance and fast vulcanization speed, and is Widely used in tire manufacturing industry. However, due to the lack of functional functional groups in the existing styrene-butadiene rubber, in the follow-up with carbon black and When silica is processed, the dispersion of carbon black and silica is poor, which affects the performance of tires. In order to make up for the defects of styrene-butadiene rubber, in The introduction of functional groups into styrene-butadiene rubber has become an effective way to solve this problem. Among various functional groups, Fluorin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08F212/14C08F236/10C08F4/58C08F4/52

CPCC08F212/14C08F236/10C08F4/58C08F4/52Y02T10/86

Inventor 李旭李福崇陶惠平宋同江张华强龚光碧董静王锋丛日新梁滔汤海鲲

Owner PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com