Composite temperature rising and controlling integrated heating element and temperature control method

A heating element and composite technology, applied in the field of tobacco, etc., can solve the problems of complex manufacturing process of heating elements, complex circuit, short circuit of heating elements, etc., to achieve the effect of improving the baking effect, simplifying the manufacturing process, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

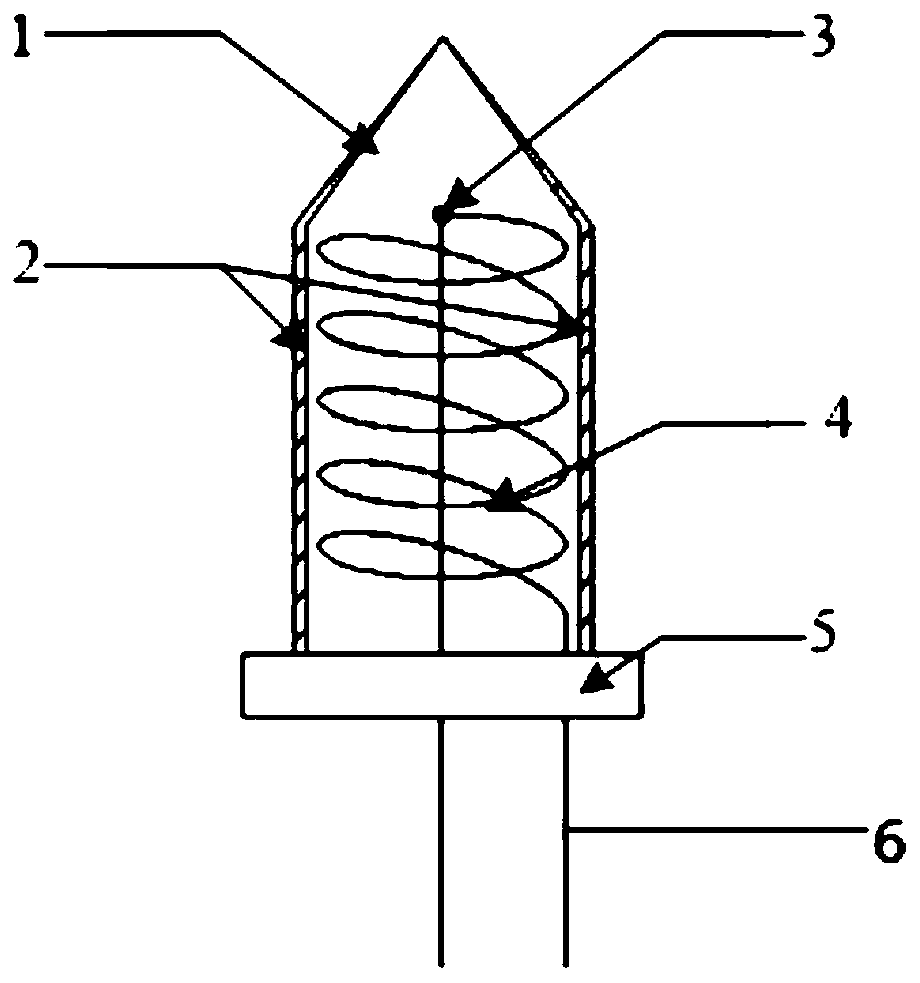

[0033] like figure 1 As shown, a composite heating element 1 with temperature rise and control includes: a casing 2 , welding points 3 , a heating element 4 , and a base 5 . No temperature measuring element other than the heating element 4 is arranged on the heating element 1 .

[0034] The heating element 1 is in the shape of a rod with a pointed end. The shell 2 is formed by pressing two metal sheets, the boundaries of the two sheets are pressed and sealed, and there is a cavity in the middle where the heating element 4 is placed. The heating element 4 is welded together at the welding point 3 by two different alloy materials, nickel-chromium alloy and nickel-silicon alloy. The heating element 4 is a helically wound wire-like structure with two heating circuit pins 6 exposing the casing 2 and the base 5 at the end. The base 5 is arranged on the bottom of the heating element.

Embodiment 2

[0036] A method for measuring the temperature of a composite heating element integrated with temperature rise and control. The heating element 1 described in Embodiment 1 is electrically connected to the positive and negative poles of the circuit control device through the two heating circuit pins 6 on it. The temperature control method comprises the following steps:

[0037] like figure 2 As shown, under temperature control (voltage is the state of = battery voltage), the electronic switch is regulated by PWM and then the supplied voltage is adjusted to the heating element 4, and its temperature is controlled; under temperature detection (voltage is 0 state ), the heating element 4 at t 0 Test the temperature of the heating element within a certain period of time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com