Egg roll processing equipment

A processing equipment and egg roll technology, which is applied in baking, pancake baking, oil/fat baking, etc., can solve problems such as difficult to guarantee the quality of egg roll processing, large differences in artificial roll materials, and affect the taste of egg rolls. The structure is simple, the production efficiency is improved, and the process is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to better understand the purpose, structure and function of the present invention, the egg roll processing equipment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

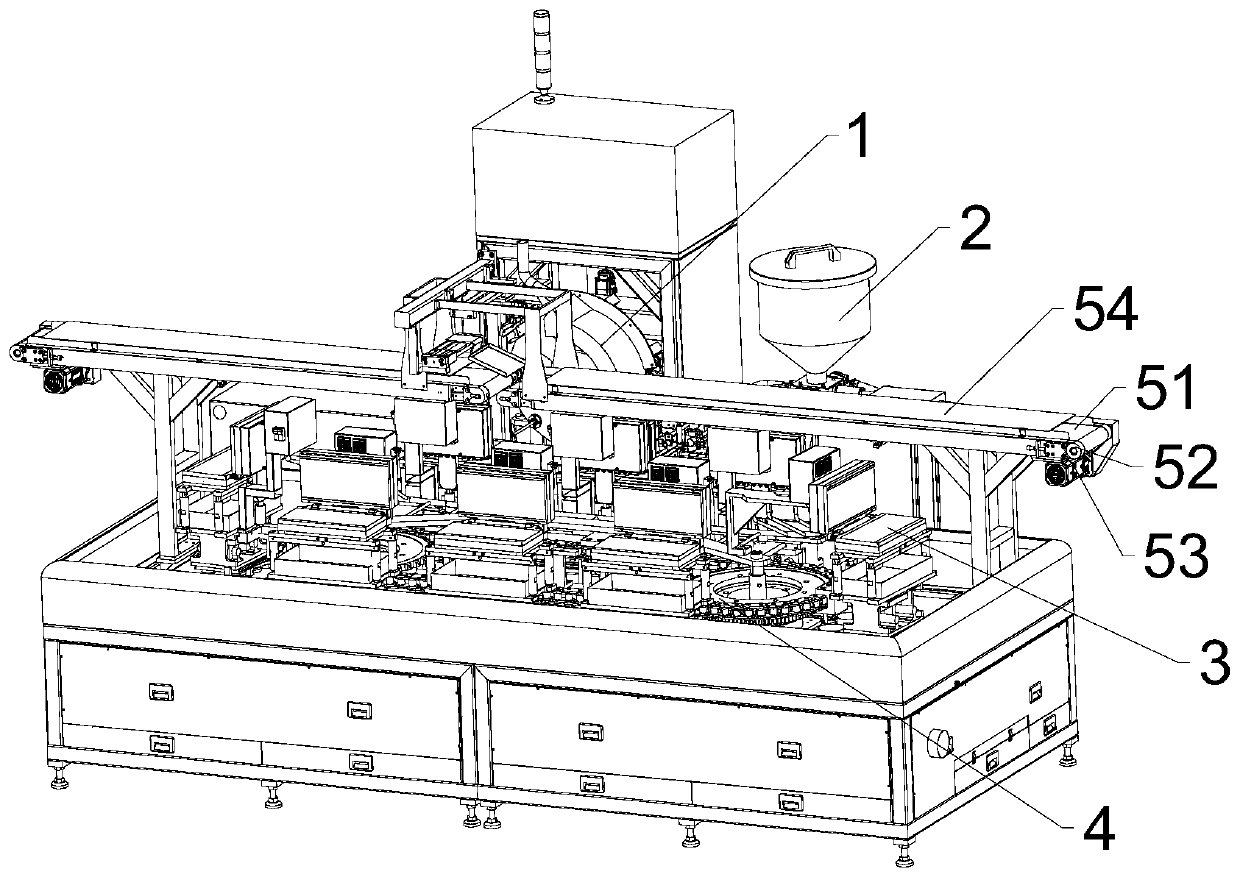

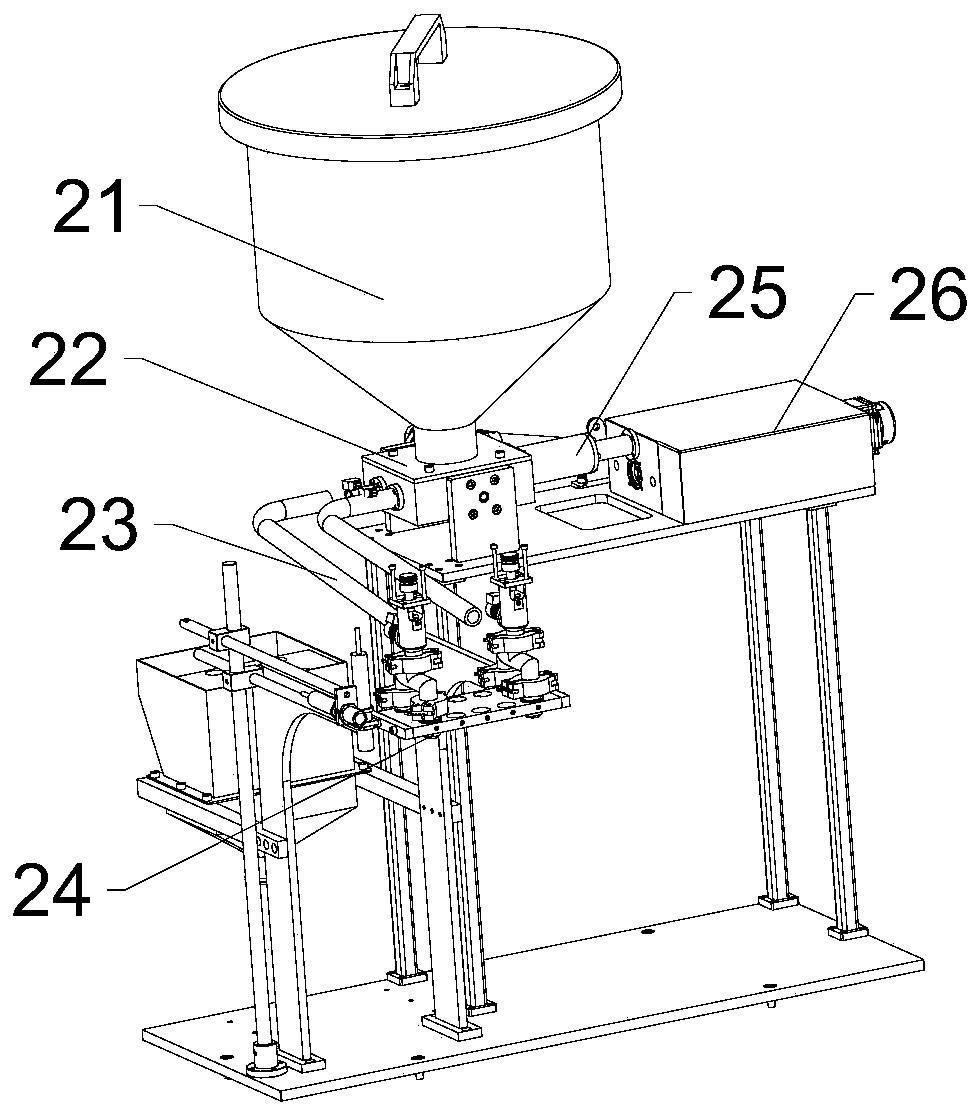

[0047] Such as Figure 1-Figure 2 As shown, the egg roll processing equipment of the present invention includes a grouting mechanism 2, a baking plate mechanism 3, a baking plate circulation mechanism 4 and an egg roll forming mechanism 1, wherein,

[0048] The baking plate mechanism 3 includes a plurality of baking plates, and the plurality of baking plates have a grouting position and a roll material position, and are used to make the slurry dripped from the grouting mechanism 2 onto the baking plate into egg roll wrappers;

[0049] The baking plate mechanism 3 is uniformly fixed on the baking plate circulation mechanism 4, and the baking plate circulation mechanism 4 drives the baking plate mechanism 3 to cycle and controls the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com