Two-dimensional optical fiber array

A two-dimensional optical fiber and array technology, applied in the direction of bundled optical fiber, etc., can solve the problems that cannot meet the requirements of two-dimensional image acquisition range and pixel positioning accuracy, and difficult positioning of optical fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

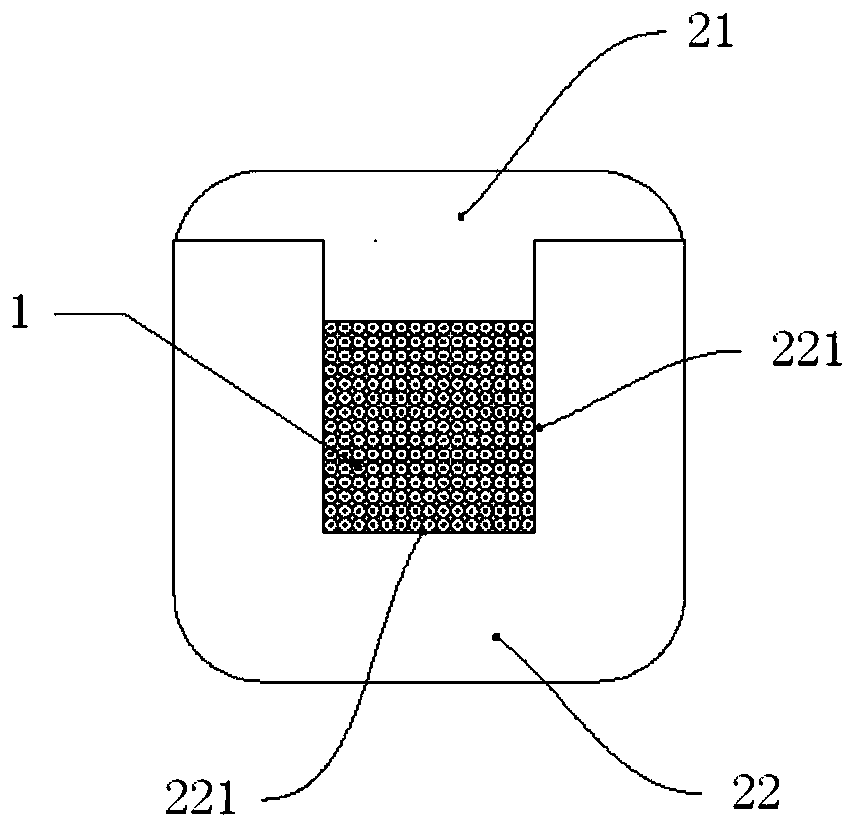

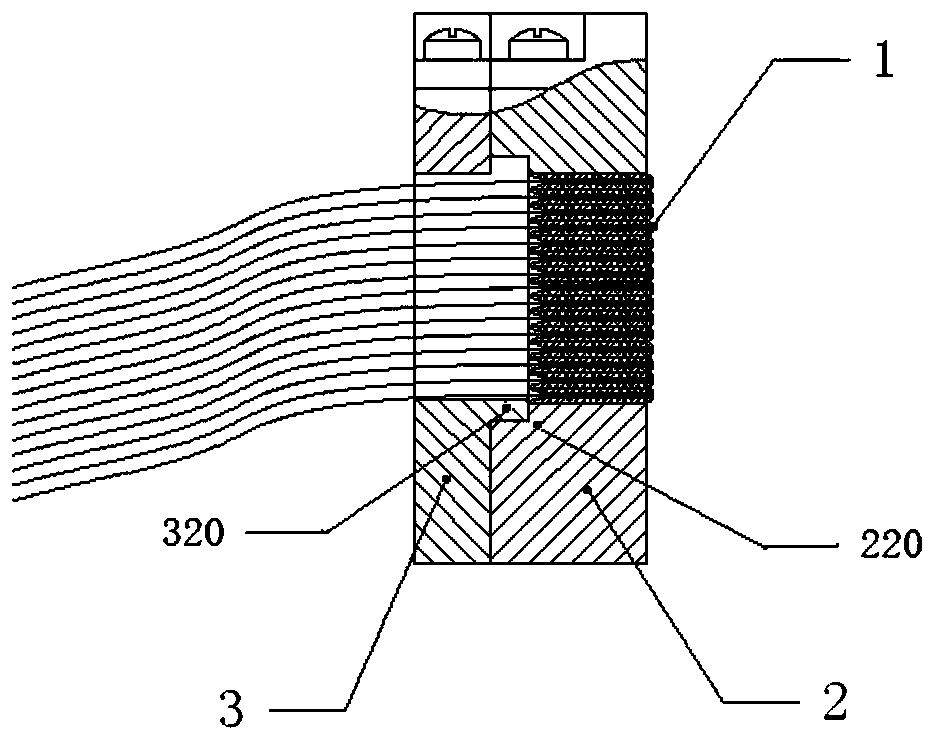

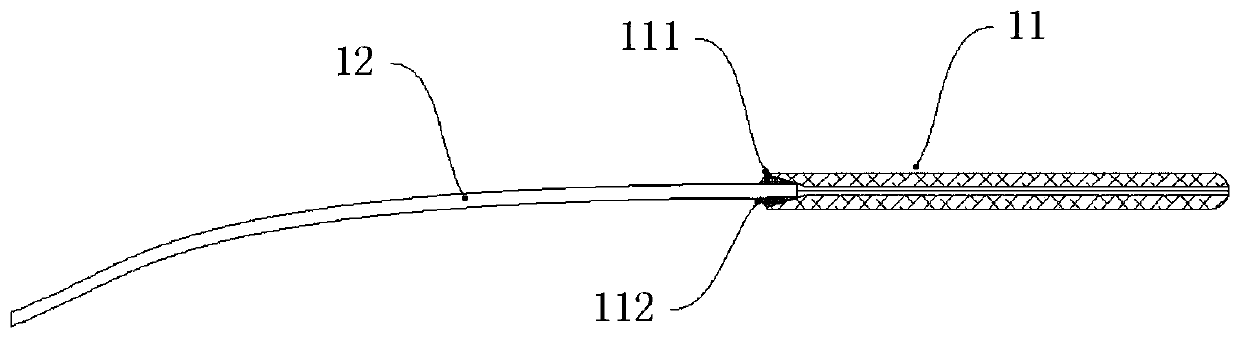

[0042] Such as Figure 1~6 As shown, this embodiment provides a two-dimensional optical fiber array for collecting large-scale, high-precision two-dimensional image information. According to the requirements of use, the effective acquisition surface of the array is 12mm×12mm, the number of pixel acquisition points is 15×15=225, and the pixel positioning error (that is, the absolute error of the core positioning in the optical fiber unit) is not greater than 0.003mm. The nominal diameter of the bare optical fiber is The 0.125mm optical cable transmits two-dimensional image information.

[0043] The difficulty in the design and production of the two-dimensional fiber array in this embodiment is that the two-dimensional fiber array is formed by orderly arrangement of 225 optical fibers, the number of fibers is large, and the positioning accuracy is high. It is possible to make a two-dimensional optical fiber array formed by arranging several or dozens of bare optical fibers with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com