Desulfurization control method and device, storage medium and electronic equipment

A control method and control device technology, applied in the field of data processing, can solve problems such as component wear, fuel loss, and desulfurization timing difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

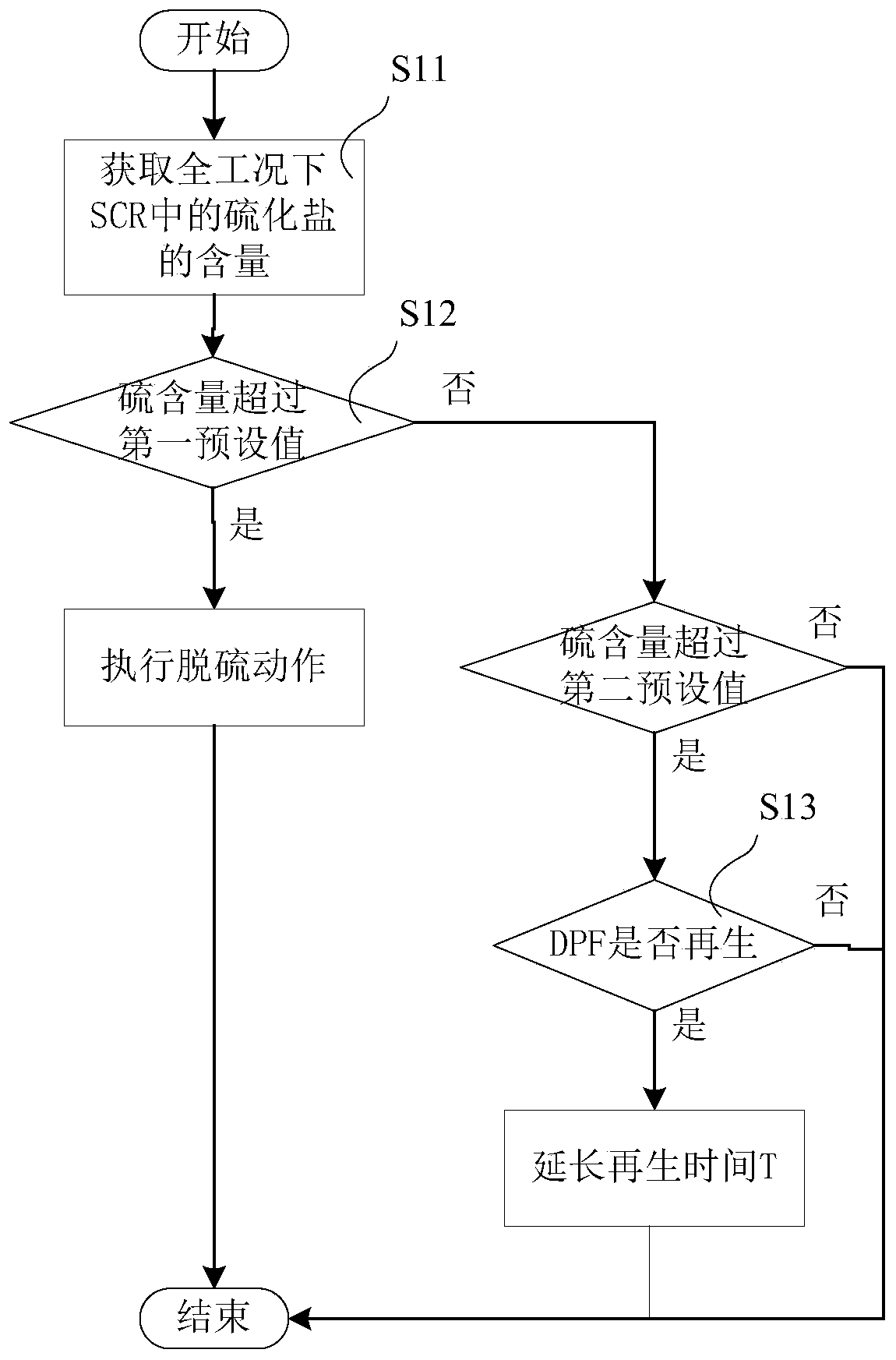

[0051] see figure 1 , figure 1 A schematic flow chart of a desulfurization control method provided by an embodiment of the present invention, the method includes:

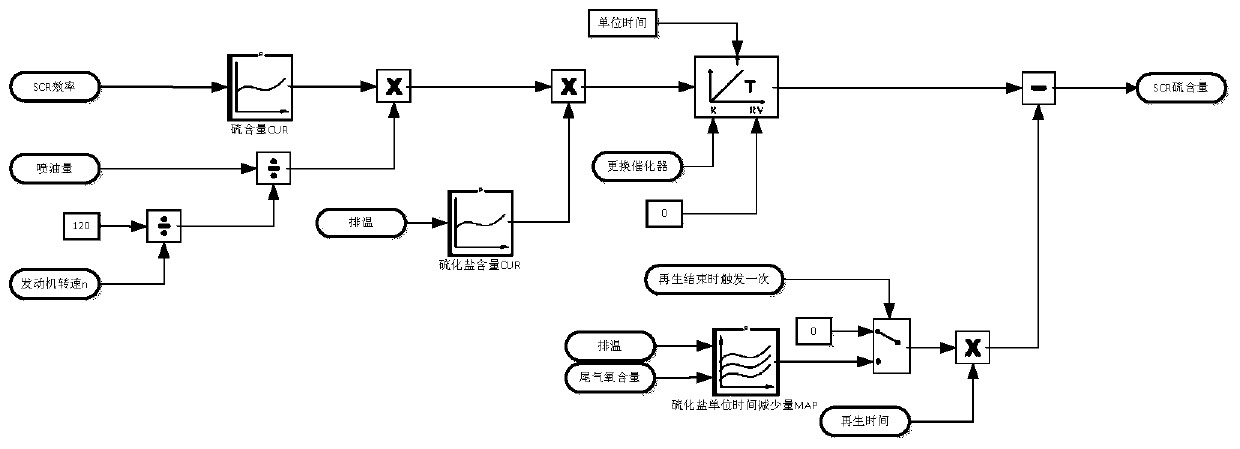

[0052] S11. Obtain the content of sulfide salt in the SCR under all working conditions;

[0053] S12. Judging whether the content of the sulfide salt is greater than a first preset value, if yes, performing a desulfurization action, if not, judging whether the content of the sulfide salt is greater than a second preset value;

[0054] S13. If yes, acquire the regeneration state of the DPF, and if the regeneration state is regeneration, control the regeneration time to a third preset value.

[0055] Wherein, the first preset value is greater than the second preset value, and the third preset value is greater than the control duration during normal regeneration.

[0056] It can be seen that in this embodiment, after obtaining the sulfide salt content in the SCR under all working conditions, judgment can be made ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com