Double-T plate joint connecting structure

A technology for connecting structures and slab seams, applied in the field of building joints, can solve problems such as easy water leakage, inconvenient construction, easy cracking, etc., and achieve the effects of good aging, convenient construction, and non-aging protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific drawings.

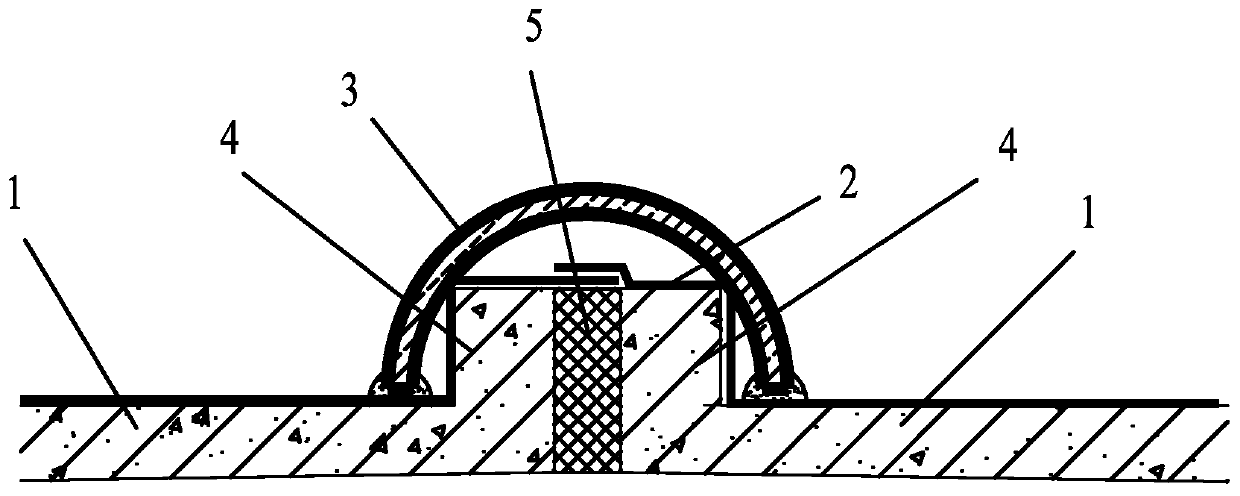

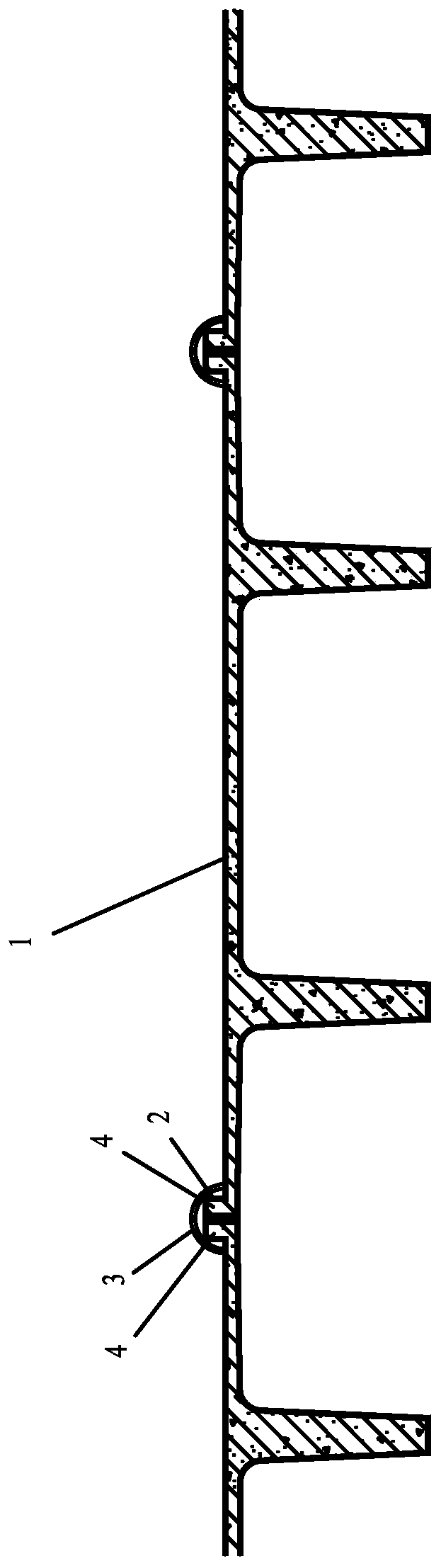

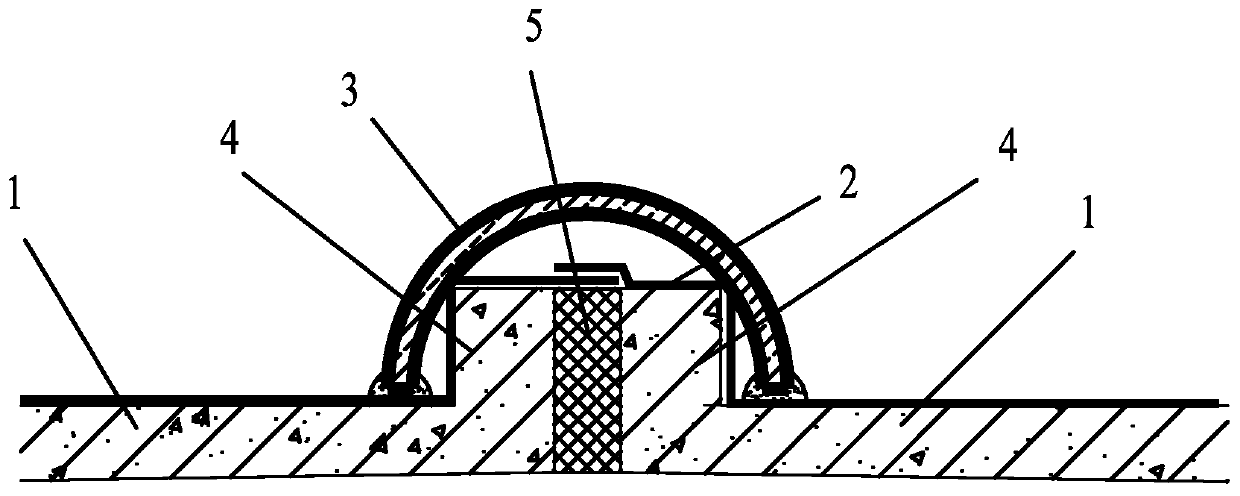

[0022] like figure 1 and figure 2 As shown, a double T board seam connection structure includes a double T board 1, a waterproof layer 2 and a curved tile 3, and the curved tile 3 is a cement ridge tile; the two ends of the double T board 1 The flanging protrusions 4 are respectively provided, and the flanging protrusions 4 are integrally formed with the double T-board 1; the gaps between every two adjacent double-T-boards 1 are filled with a buffer material 5, and the upper surface of the double-T-board 1 is provided with a waterproof layer 2. The waterproof layer 2 covers the cushioning material 5 at the same time; every two adjacent double T-boards 1 are covered with arc-shaped tiles 3 at the upper joints.

[0023] The arc-shaped tile 3 is fixed on the double T-board 1 by mortar.

[0024] Preferably, the cushioning material 5 uses a polyurethane foaming agent.

[0025]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com