A multi-station universal joint special-shaped automatic chamfering machine

A universal joint and multi-station technology, which is applied in the direction of machine tools, manufacturing tools, and grinding workpiece supports suitable for grinding the edge of workpieces, and can solve the problems of scratching the dust cover, low precision, jamming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

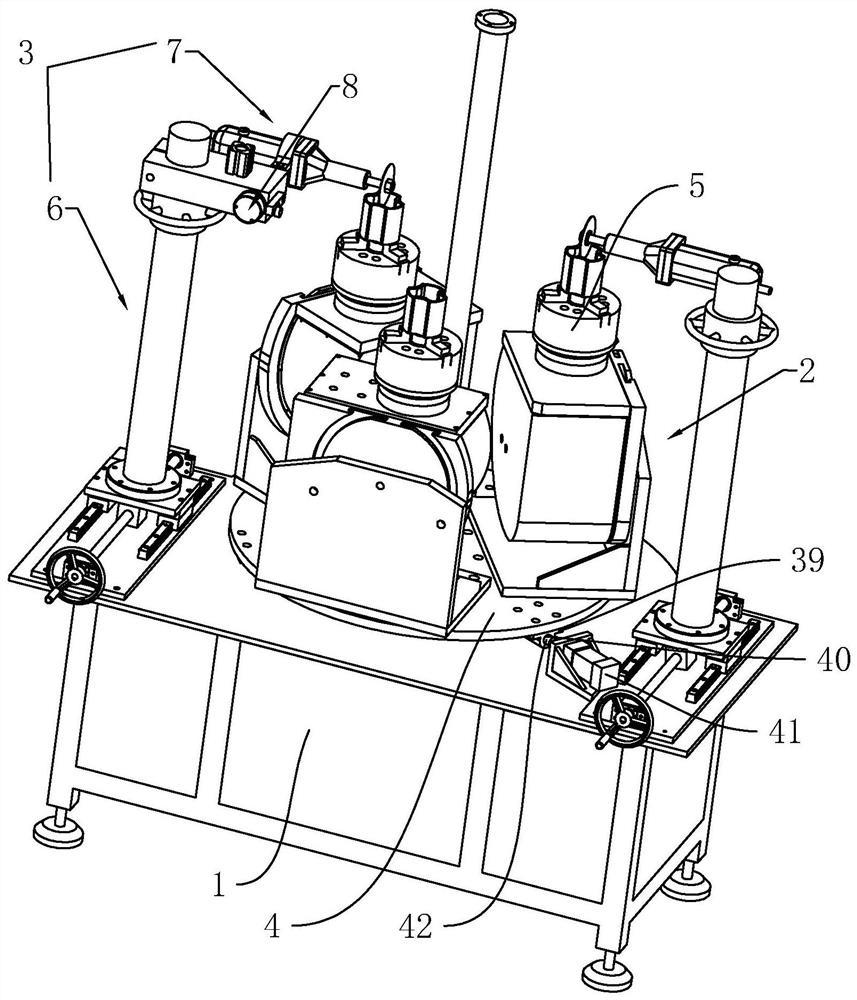

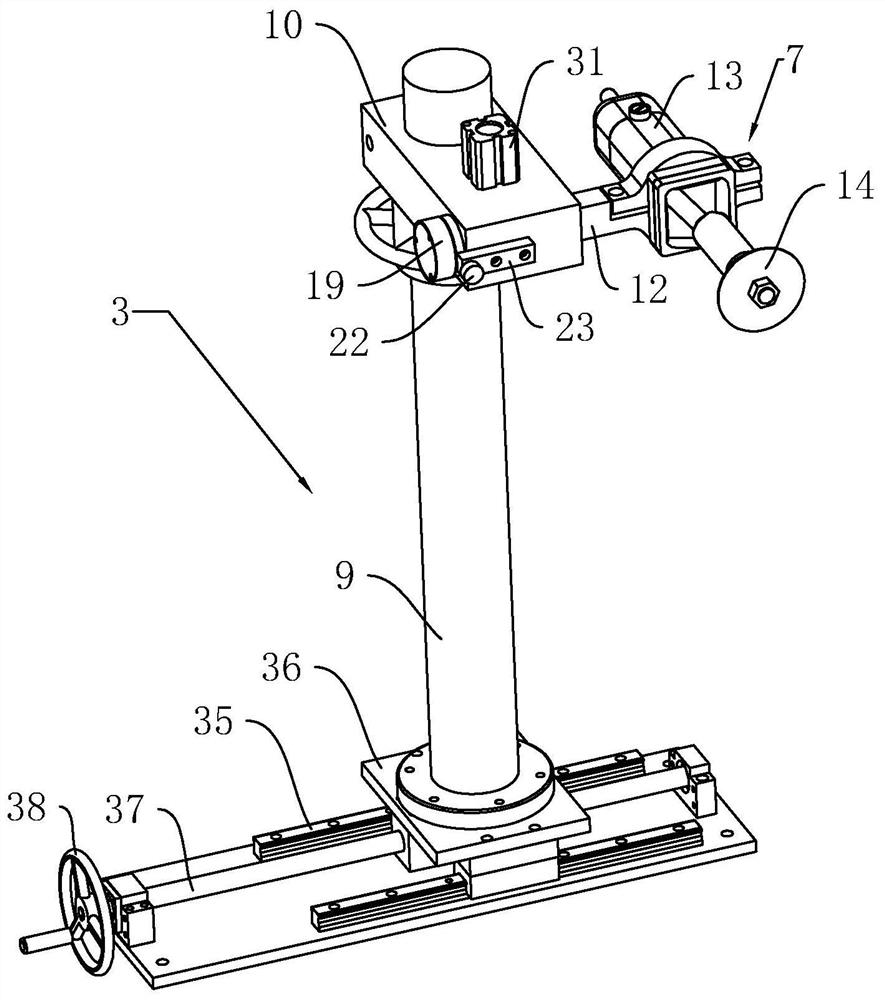

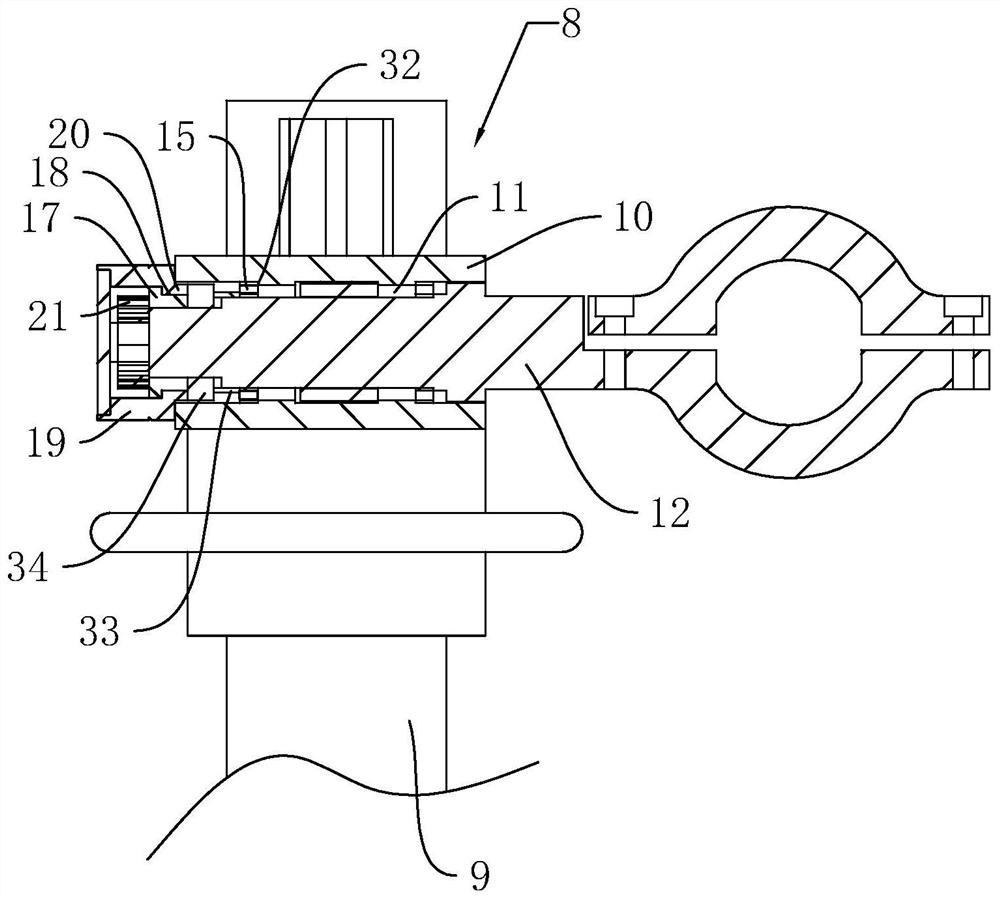

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0037] refer to figure 1 and figure 2 , is a multi-station universal joint special-shaped automatic chamfering machine disclosed by the present invention, comprising a machine body 1 fixed on the ground, a feeding mechanism 2 arranged on the body 1 and a chamfering mechanism 3 arranged on the body 1, The feeding mechanism 2 includes a drive disc 4 that is rotatably connected to the body 1 and driven by a motor, at least two rotating motors that are connected to the drive disc 4, and a clamping member 5 that is connected to the rotating motor. The clamping member 5 here can adopt three Jaw chucks, and the optimal choice is three, the universal joint is clamped on one of the clamping parts 5, and the drive disc 4 is driven by the motor to rotate so as to drive the workpiece to be transferred to the next station. The chamfering mechanism 3 includes a The body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com