SNCR denitration automatic control method and system thereof

An automatic control system and control module technology, applied in the field of flue gas denitrification, can solve the problems of low automation, poor flexibility and poor stability of SCNR system, and achieve the effect of reducing the number of manual adjustments, reducing workload and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

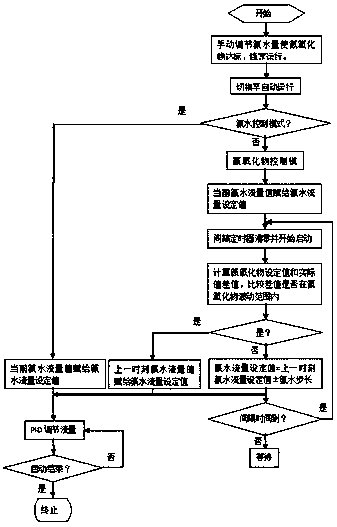

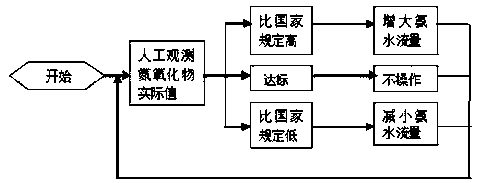

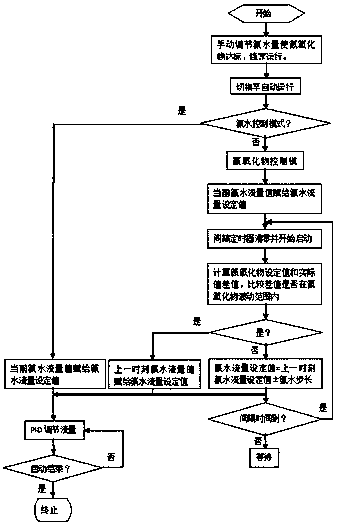

[0087] First aspect, such as figure 1 Shown, the first embodiment: a kind of SNCR out-of-stock automatic control method, wherein, comprises the following steps:

[0088] Step 1: Adjust the flow rate of ammonia water until the nitrogen oxide reaches the standard, and record the amount of ammonia water used as the amount of ammonia water V1;

[0089] Step 2: Determine whether to use the ammonia water control mode;

[0090] Step 3: If the ammonia water control mode is adopted, the ammonia water flow value V1 is assigned to the ammonia water flow set value V0, and the PID controls the ammonia water pump to adjust the ammonia water flow according to the ammonia water flow set value V0, and the actual flow of ammonia water is recorded as the feedback value V2;

[0091] If the ammonia water control mode is not used, the nitrogen oxide control mode is directly adopted;

[0092] Step 4: Using the nitrogen oxide control mode, measure the flow rate of ammonia water at intervals (inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com