Automatic quick response temperature measurement for rotary kilns

A temperature measurement and rotary kiln technology, applied in the field of temperature devices, can solve problems such as high risk of injury and health problems, and achieve the effects of increasing work safety, reducing personnel costs, and good process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

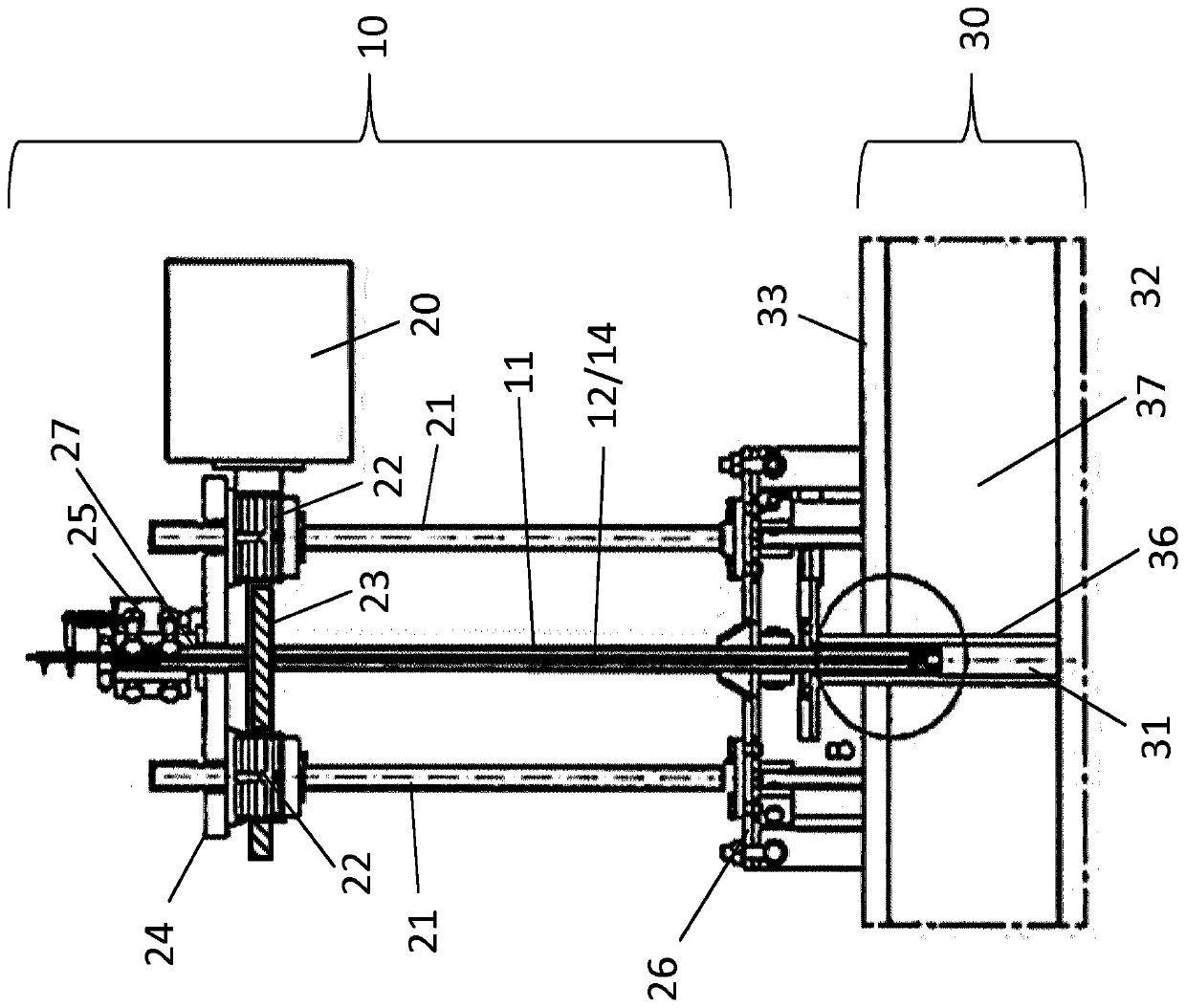

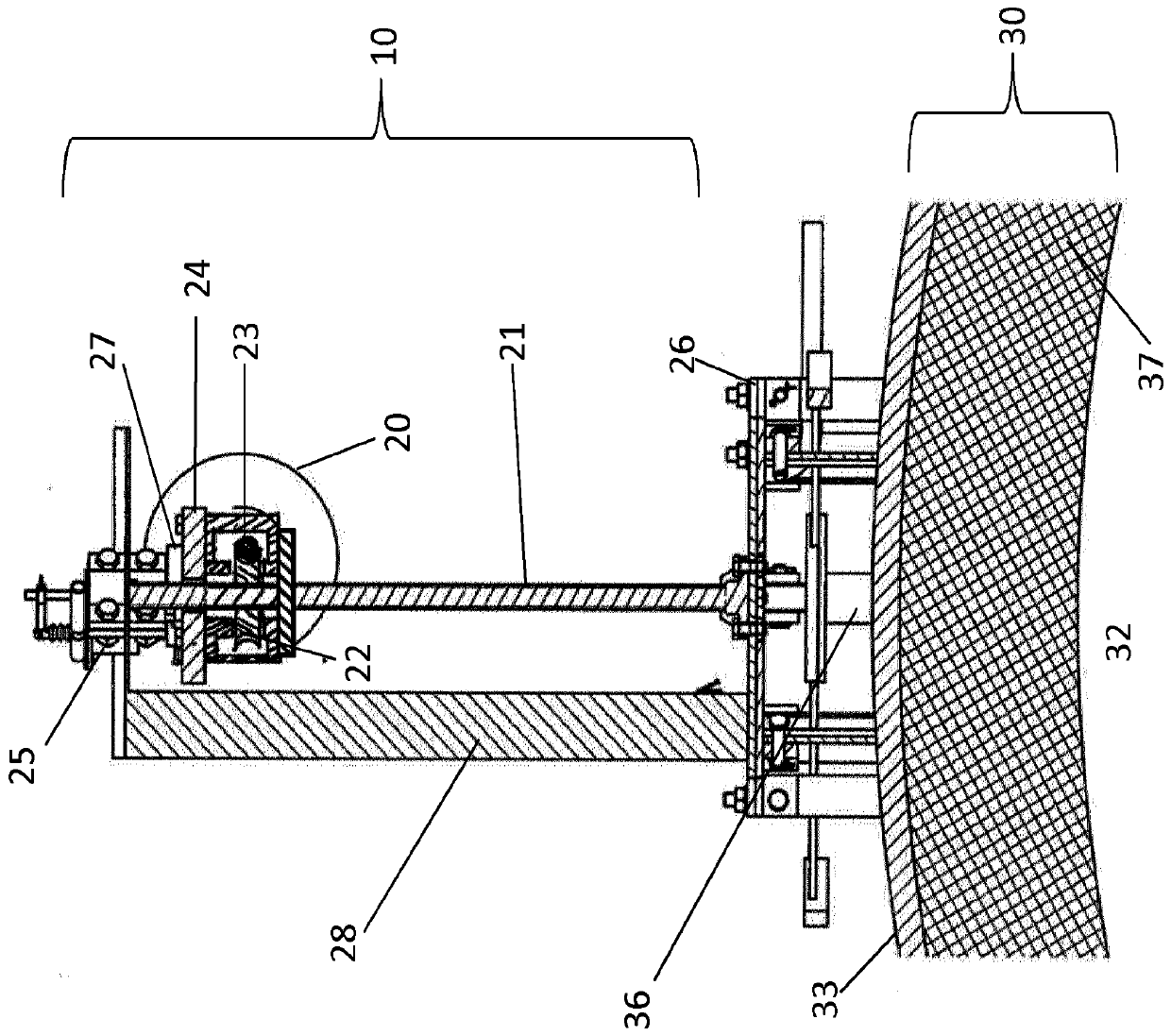

[0057] figure 1 A first semi-automatic embodiment of the invention is shown. Therein, the device 10 is mounted on a rotary kiln housing 33 and performs the working steps for temperature measurement.

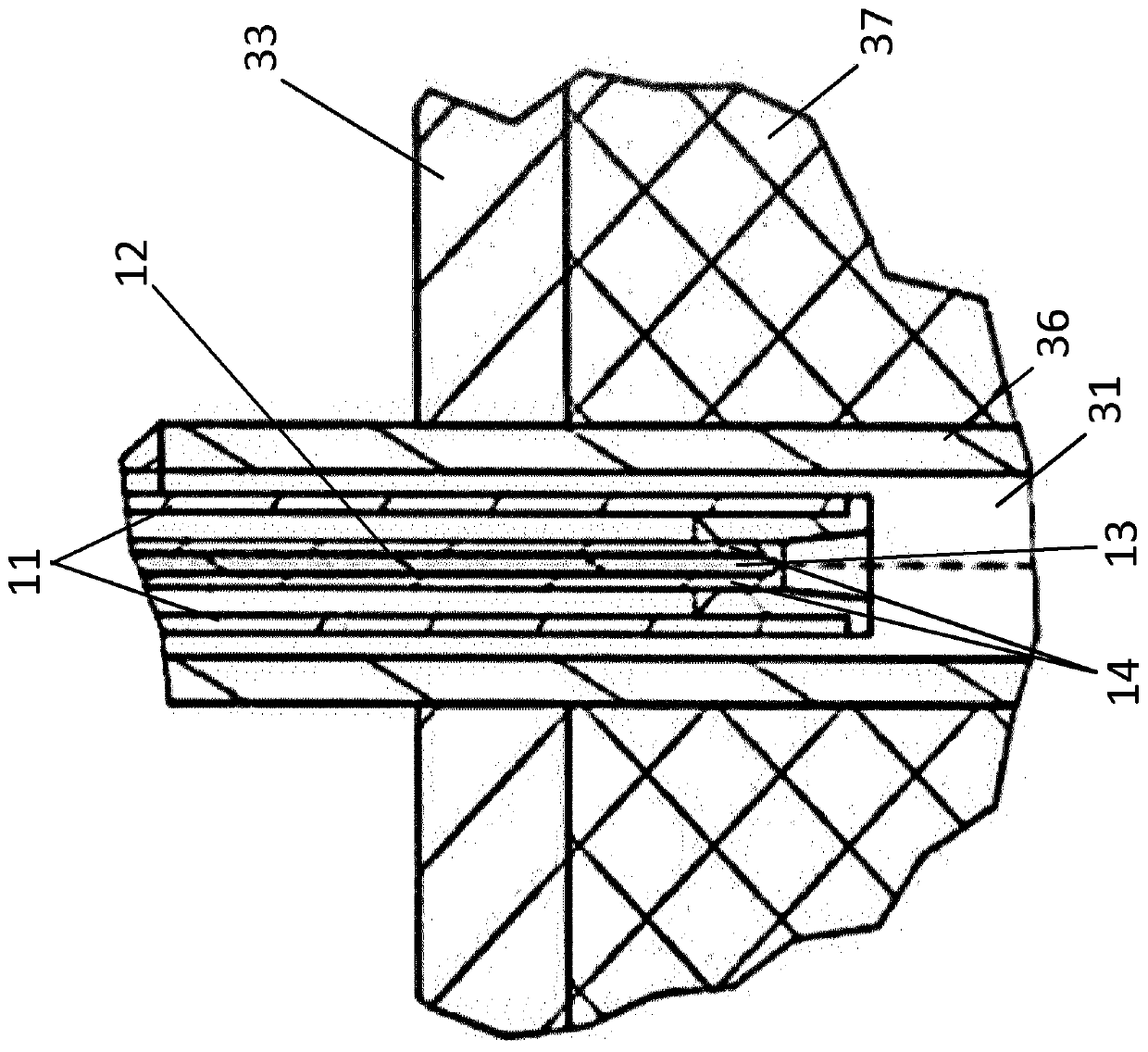

[0058] Specifically, the thermocouple 12 is located in the elongated hollow body 11 . In order to obtain a high response speed, its measuring end 13 is either permanently outside the elongated hollow body 11, or the thermocouple 12 can be moved independently so that its end 13 moves into and out of the elongated hollow body 11 . The thermocouple 12 is preferably protected by a protective tube 14, leaving the measuring tip 13 exposed to allow a rapid response to temperature changes.

[0059] In the latter case, preferably, the tip 13 can be positioned outside the elongated hollow body 11 by means of an actuator 25 on top of the elongated hollow body 11 . The actuator 25 moves the thermocouple 12 together with the protection tube 14 . In the standby position, the elongated ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com