A kind of concrete and frp bonding interface shear strength and stiffness testing device and method

A technology of shear strength and testing device, which is applied in the direction of measuring device, using a stable shear force to test the strength and strength characteristics of materials, etc. The shear stiffness cannot be accurately obtained, and there is no test of the shear performance of the concrete and FRP interface, so as to avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

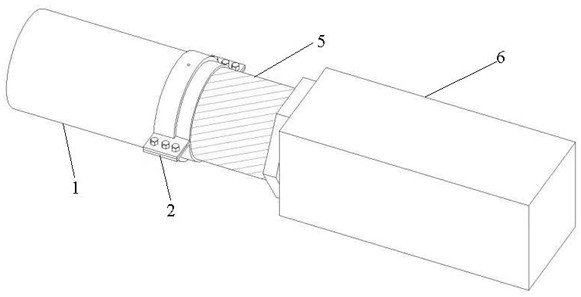

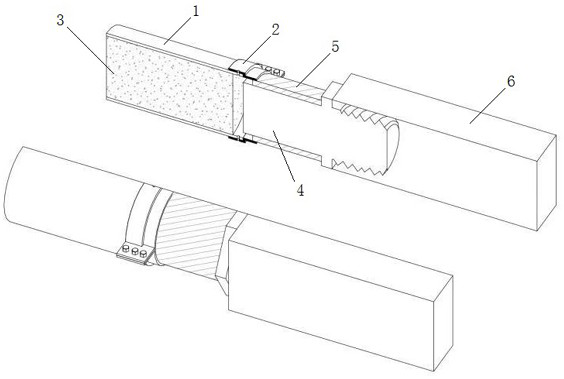

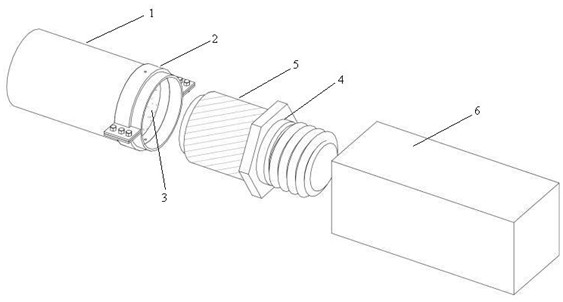

[0050] This embodiment provides a device for testing the shear strength and stiffness of the concrete and FRP bonding interface, including an outer sleeve 1, a connecting rod 4 and a tightening sealing ring 2; The outer diameter of the barrel 5 is the same; the connecting rod 4 includes a round rod part 4-1 for tightly socketing with the FRP sleeve 5 and a threaded part 4-3 for connecting with the threaded hole of the torsion joint 6; the round rod part 4 The end of the -1 is located outside the FRP sleeve 5; the tightening seal ring 2 includes two half tightening rings 2-1 and bolts 2-3 connecting the two half tightening rings 2-1; the half tightening ring 2 -1 includes a first half-ring body, a second half-ring body, and bolt connection ears arranged on the first half-ring body and the second half-ring body; the inner diameter of the first half-ring body is consistent with the outer diameter of the outer sleeve 1 , is provided with a binder injection hole 2-2; the inner diam...

Embodiment 2

[0059] The present embodiment provides a method for testing the shear strength and stiffness of the bonding interface between concrete and FRP, which is performed using the device for testing the shear strength and stiffness of the bonding interface between concrete and FRP described in Example 1, including the following steps:

[0060] S1, pour concrete 3 into the outer sleeve 1, vibrate and compact, maintain, remove the laitance after completion, and put it into an incubator for heat preservation after curing and molding;

[0061] S2, quickly wrap the heated FRP sleeve 5 on the round rod portion 4-1 of the cooled connecting rod 4, using the principle of thermal expansion and contraction, when the connecting rod 4 and the FRP sleeve 5 return to normal temperature, the FRP sleeve 5 sets tightly on the round rod part 4-1;

[0062] S3, apply lubricant (such as Vaseline) to the bottom surface of the overhanging part of the round rod part 4-1, and the end of the round rod part 4-1...

Embodiment 3

[0077] The difference between this embodiment and Embodiment 2 is:

[0078] In the step S1, the inner diameter of the outer sleeve 1 is 100mm~200mm, the height is 100mm~200mm, and the thickness is 20-40mm; after the concrete 3 is cured and formed, it is placed in a temperature of 20°C±2°C and a relative humidity of 65±5%. Cured in the environment for 28 days to form concrete-filled steel tubular columns;

[0079] In the step S2, the round rod portion 4-1 is 1-3 mm longer than the FRP sleeve 5, and the diameter is slightly larger than the inner diameter of the FRP sleeve 5, so as to realize an interference fit; the diameter of the adhesive injection hole 2-2 is about 2mm; the connecting rod 4 is put into the freeze-thaw test box to cool down by 50°C, and the FRP sleeve 5 is put into the temperature test box to heat up by 30°C. After 8 hours, take it out, and use the principle of thermal expansion and cold contraction to set the FRP sleeve 5 into the round rod part 4-1 to achie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com