A combined fireworks automatic production line

An automated production line, combined fireworks technology, applied in the direction of fireworks, offensive equipment, weapon types, etc., can solve the problems of inadequate safety measures, restricting the development of the fireworks industry, low explosion-proof level, etc., to facilitate maintenance, replacement and upgrades, and improve production efficiency. , to ensure the effect of production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

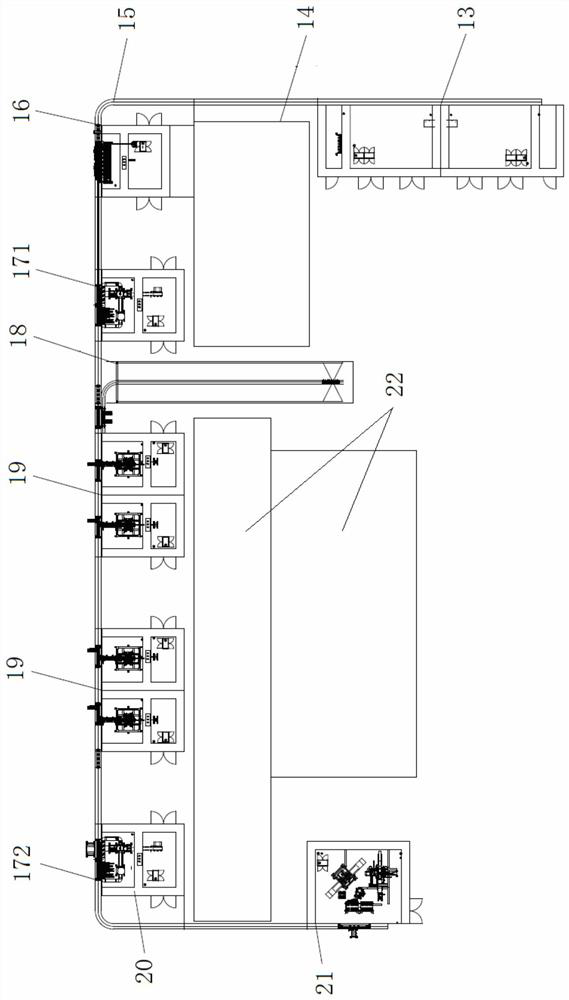

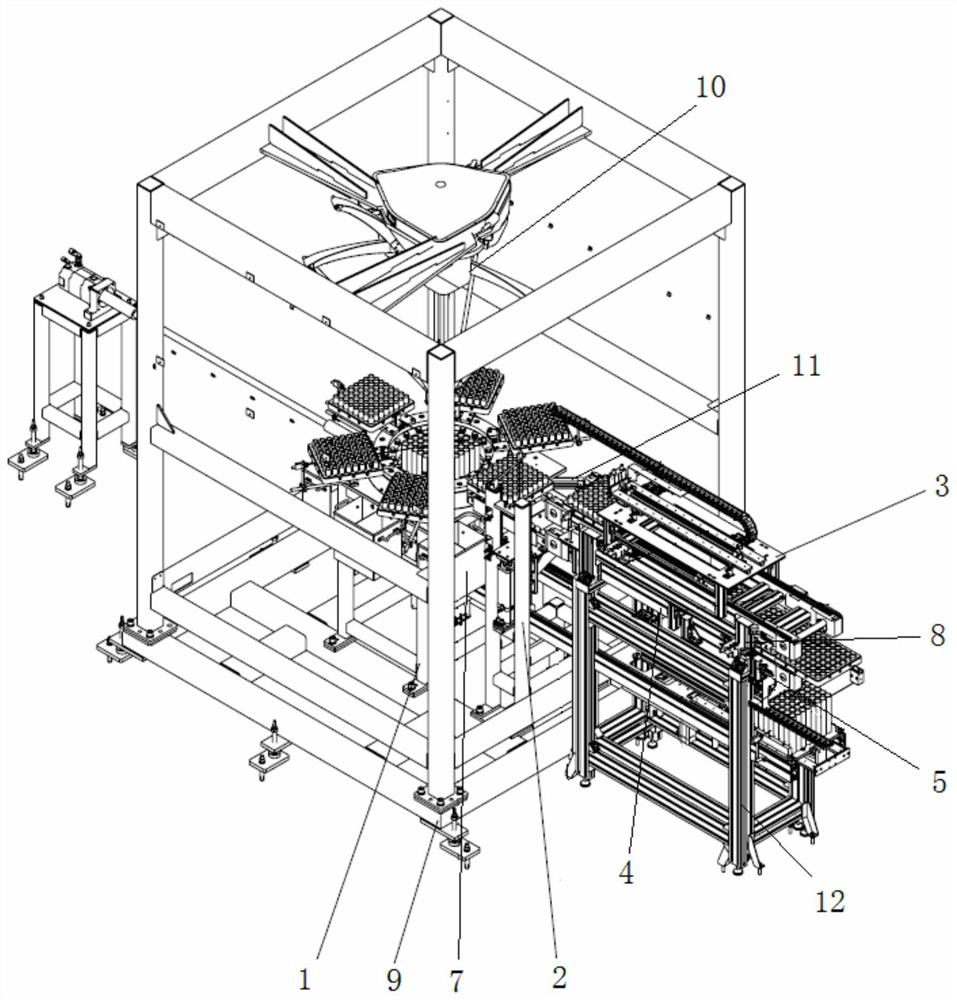

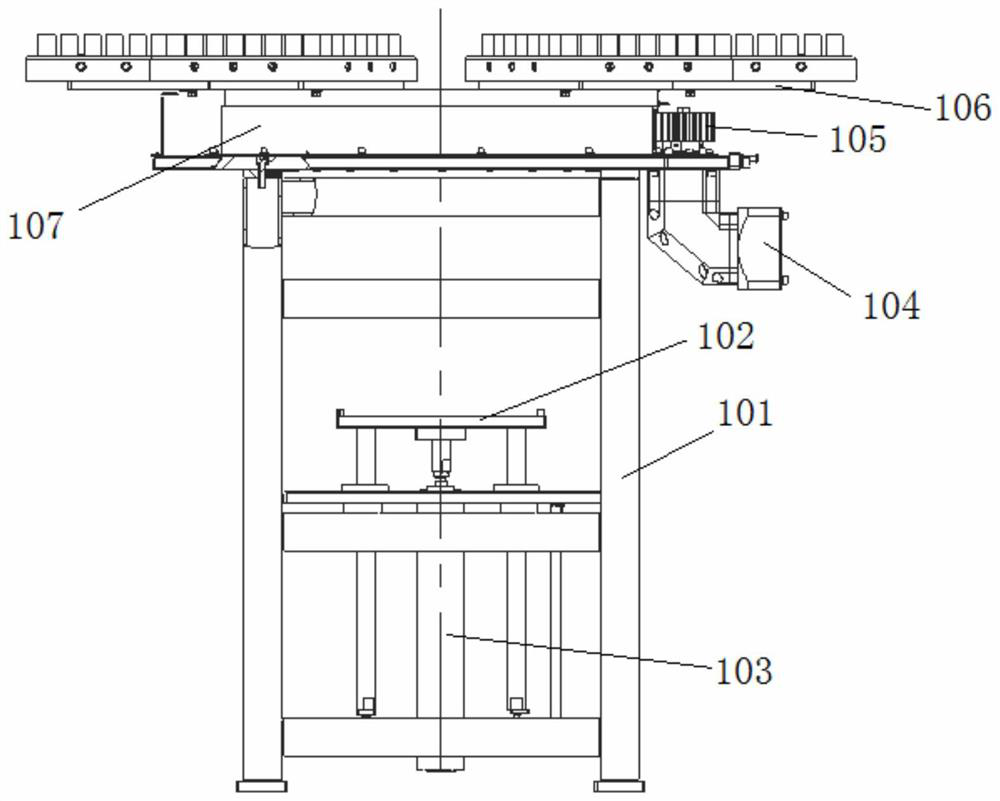

[0035] Such as figure 1 As shown, the present invention comprises a potted flower conveying line 15 and an inner tube conveying line 18, and on the described potted flower conveying line 15, along the transmission direction of the potted flower composition, a group pot connecting device 13, a nitrating device 16, a first Press paper baba device 171, cast inner cylinder device 19, second paper press baba device 172 and packaging stacking device 21, the output end of inner cylinder conveying line 18 is connected with described throwing inner cylinder device 19, and described potted flower conveying line 15 It is concave, and a first explosion-proof embankment 14 is provided between the inner cylinder conveying line 18 and one side of the potted flower conveying line 15, and a second explosion-proof embankment is provided between the inner cylinder conveying lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com