Tea grinding oven

A technology for tea stove and tea leaves, which is applied in the directions of stove, stove type, tea drying, etc., can solve the problems of maintaining fragrance and greenness, and cannot evenly disperse tea leaves, so as to achieve the effect of facilitating the formation of fragrance and preventing the diffusion of fragrance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

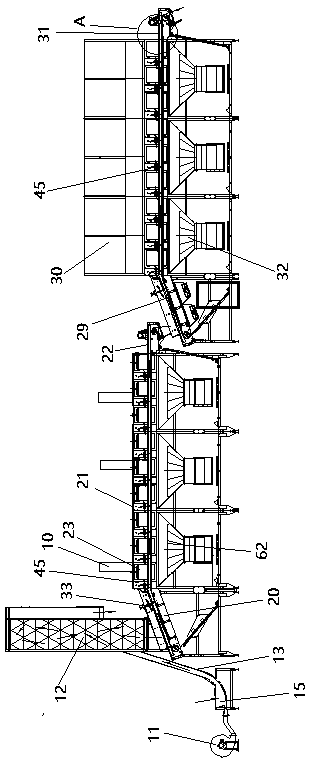

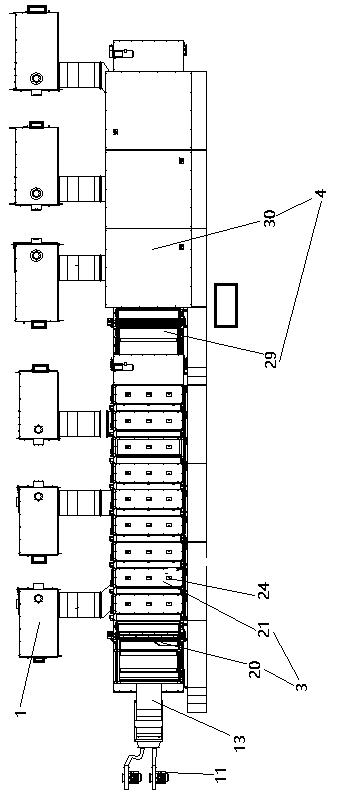

[0030] Embodiment one, see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 , a kind of tea-grinding stove, comprises hot-air generator 1 and the air-sent loose tea machine 2 that connects together successively, tea primary drying machine 3 and tea re-drying machine 4.

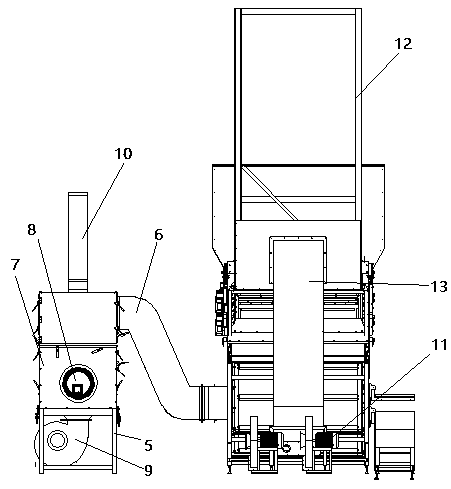

[0031] There are 6 hot air generators in this embodiment. Hot blast generator comprises hot blast generator frame 5, is arranged on the casing 7 that is provided with hot blast outlet 6 on the hot blast generator frame, is positioned at the combustion furnace 8 in casing and is connected together with casing so that air flows through casing The second blower blower 9 that flows out from the hot blast outlet afterward. The combustion furnace is provided with a tail gas discharge pipe 10 .

[0032] The wind blowing loose tea machine comprises a first air blower 11 and a cylindrical body 12 with a closed upper end and an open lower end. The side wall of the barrel is prov...

Embodiment 2

[0039] Embodiment two, the difference with embodiment one is:

[0040] see Figure 8 and Figure 9 , Tea primary drying machine and tea re-drying machine are equipped with conveyor belt anti-clogging mechanism and the setting method is the same. Taking the tea re-drying machine as an example, the specific description is as follows:

[0041] The conveyor belt anti-blocking mechanism includes a positioning block 54, a pendulum 55 hinged on the frame of the re-dryer through a pendulum 58, a pendulum 56 connected to one end of the pendulum and pressing the other end of the pendulum to make the pendulum swing and drive the pendulum. The hammer hits the pressing head 57 of the portion between the driving roller of the first re-drying machine part and the driving roller of the second re-drying machine part by hammering the tea conveyor belt of the re-drying machine part. The pressing head is connected on the rotating shaft 59 . The pendulum shaft, the rotating shaft and the drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com