Double-power single-pass drive heat pump with double-clutch gearbox switched

A dual-clutch gearbox and dual-power technology, applied in the field of heat pumps, can solve the problems affecting the continuity of heating, direct heat emission, and low output, and achieve the effects of improving the utilization rate of primary energy, saving operating costs, and maintaining continuous and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

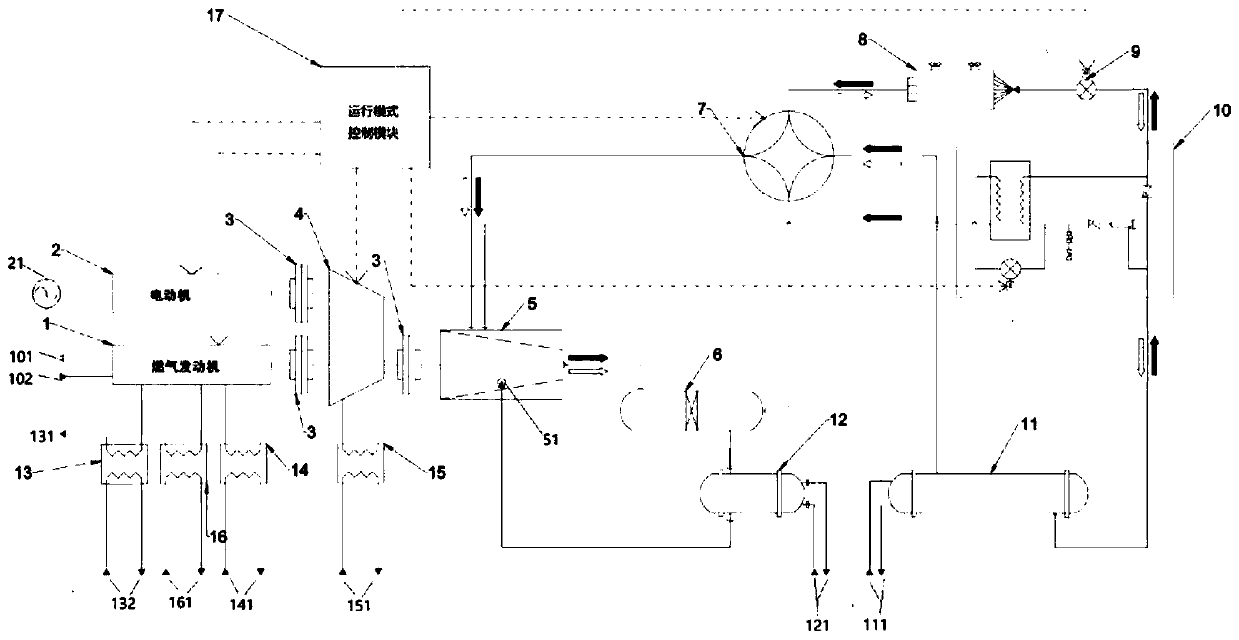

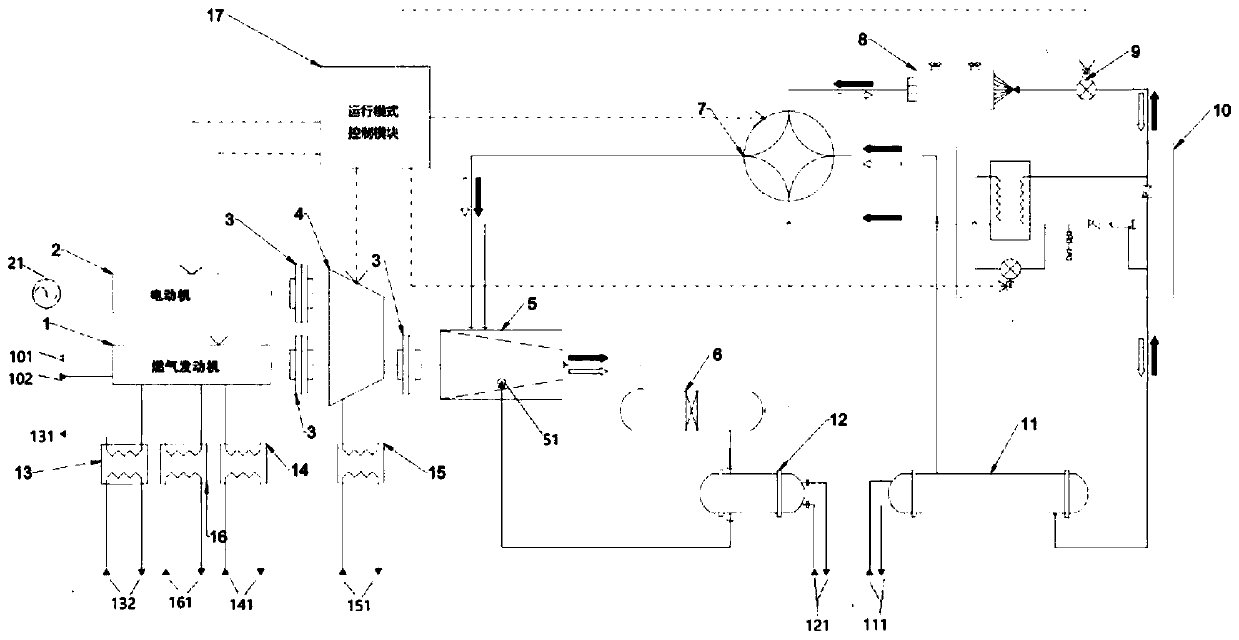

[0029] Such as figure 1 As shown, a dual-power single-pass drive heat pump switched by a dual-clutch gearbox in a preferred embodiment of the present invention includes a drive module, a compression module, a power control switching module, a heat exchanger module and an operating mode control module; the drive The module includes a gas engine 1 and an electric motor 2; the power control switching module is configured to accept the command of the operation mode control module, select the input of the gas engine 1 to drive the compression module to heat, or select the input of the electric motor 2 to drive the The compression module heats / cools; the heat exchanger module is configured to output cooling / heat; the compression module is configured to complete a refrigeration / heating cycle through a refrigerant.

[0030] In this embodiment, the compression module selects the compressor 5; the power control switching module includes a coupling 3 and a dual-clutch gearbox 4; the heat...

Embodiment 2

[0037] In order to improve the multi-directional application of energy cascades and improve the utilization rate of primary energy, preferably, a heat recovery delivery waterway system is set up. The heat recovery delivery waterway system includes a heat recovery module and a waterway system. The heat recovery module is used to recover the gas engine 1. Waste heat generated by dual clutch gearbox 4 and compressor 5. Preferably, a flue gas heat exchanger 13 , a jacket water heat exchanger 16 , an intercooler water heat exchanger 14 , a dual-clutch gearbox heat exchanger 15 , and an oil cooler 12 are provided. Preferably, it is divided according to the temperature range of the heat recovered by each heat exchanger. According to the energy demand, the recovered heat of one heat exchanger can be selected for direct use, or the recovered heat of several heat exchangers can be combined and output. Flue gas heat exchanger 13, cylinder jacket water heat exchanger 16, intercooler water...

Embodiment 3

[0040] This embodiment combines figure 1 The flow direction of the refrigerant as shown by the hollow arrow in the figure describes the refrigeration and defrosting working process of the present invention in detail.

[0041] Similar to the control process of the first embodiment and the second embodiment, the system control cabinet 17 judges the defrosting working condition according to the difference between the surface temperature of the finned heat exchanger 8 and the air temperature. The system control cabinet 17 issues instruction information to the four-way valve 7, switches the four-way valve 7, changes the flow direction of the refrigerant in the system, and switches to the cooling working condition. The refrigerant is compressed by the compressor 5 to form a high-temperature and high-pressure gas. After entering the oil-gas separator 6, the gas passes through the switched four-way valve 7 and enters the finned heat exchanger 8 to exchange heat with the air. The gas c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com