A method for treating self-sustained combustion of VOCs by catalytic ignition at room temperature

A technology of catalytic ignition and treatment method, applied in combustion methods, combustion types, incinerators, etc., can solve the problems of difficult recycling and comprehensive utilization, insufficient attention to waste gas emission treatment, small total amount, etc., and achieve good water quality. Thermal stability and high temperature stability, good catalytic combustion activity, environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

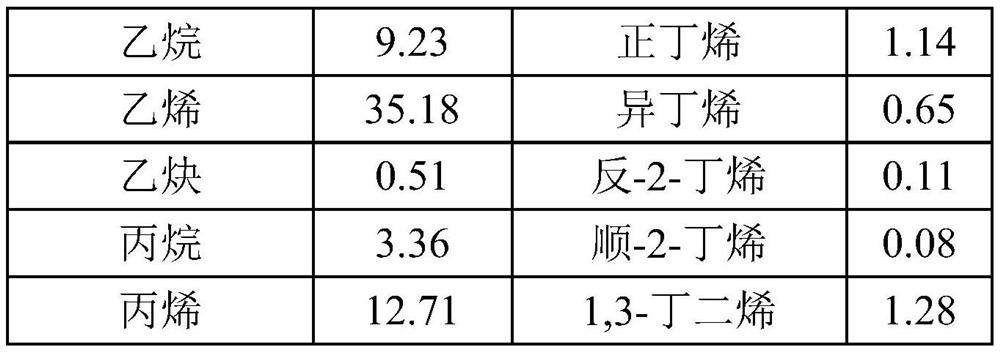

[0035] This example is used to illustrate a method for treating VOCs waste gas containing a certain amount of low unsaturated hydrocarbons by catalytic ignition at room temperature of the present invention.

[0036] The finished catalyst A was loaded into the reactor, and the catalyst loading amount was 0.02L, accounting for 80% by volume of the fixed bed reactor. When the temperature of the catalyst bed in the reactor equipped with the doped noble metal composite oxide catalyst is 33 °C, the volume flow rate of VOCs waste gas of 12 L / h (the composition is shown in Table 1) and 1.5 L / h of hydrogen Pass into the reactor together, and then pass in 20L / h of air to make the VOCs waste gas catalytically ignite, and the temperature of the catalyst bed is rapidly raised to 450 °C; enter the catalytic self-sustained combustion stage, and then stop the flow of hydrogen and reduce the volume of VOCs waste gas. The flow rate was adjusted to 6L / h, and air with a volume flow of 75L / h was i...

Embodiment 2

[0045] This example is used to illustrate a method for treating VOCs waste gas containing a certain amount of low unsaturated hydrocarbons and hydrogen by catalytic ignition at room temperature of the present invention.

[0046] The finished catalyst A was loaded into the reactor, and the catalyst loading amount was 0.02L, accounting for 80% by volume of the fixed bed reactor. When the temperature of the catalyst bed in the reactor equipped with the doped noble metal composite oxide catalyst is 33 °C, the VOCs waste gas (the composition is shown in Table 2) with a volume flow of 12 L / h is passed into the reactor, and then Introduce 20L / h of air to catalyze the ignition of VOCs waste gas, and the temperature of the catalyst bed is rapidly raised to 450°C; enter the catalytic self-sustained combustion stage, then adjust the volume flow of VOCs waste gas to 6L / h, and feed 75L / h With the volume flow of air, the temperature of the catalyst bed rapidly increased to about 650 °C, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com