Wax-removing and preventing oil pipe unit, wax-removing and preventing oil pipe and preparation method of wax-removing and preventing oil pipe unit

A wax oil pipe and oil pipe technology is applied in the field of wax removal and anti-wax oil pipe units (unit pipes), which can solve the problems that the heat preservation oil pipe cannot be used for heavy oil production operations and wax removal, high cost, and bulky volume, so as to avoid the phenomenon of wax deposition. , The effect of reducing oil well load and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

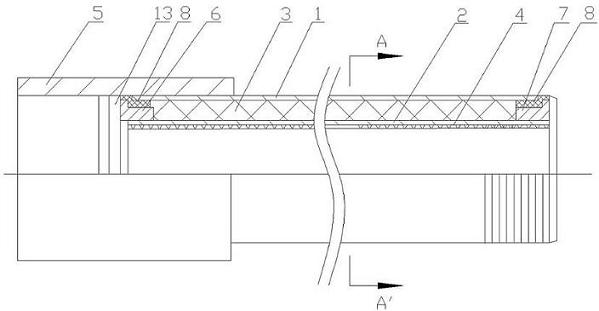

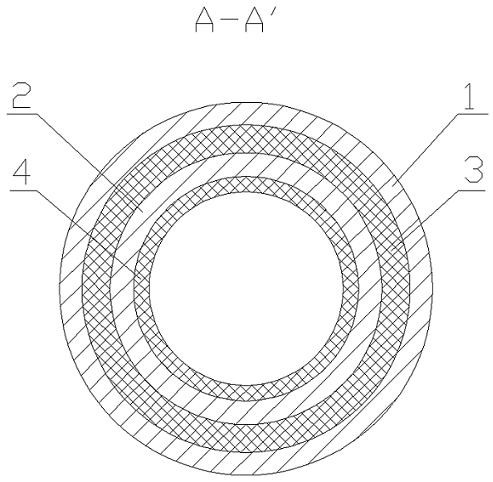

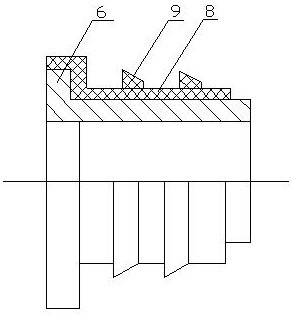

[0070] see figure 1 and figure 2 , the wax-removing oil pipe unit of the present invention comprises oil pipe body 1, and described oil pipe body can be common oil pipe, and the inner pipe 2 coaxial with it is arranged in described oil pipe body, leaves between described oil pipe body and described inner pipe. There is a gap, and the gap is filled with thermal insulation material, and the thermal insulation material fills the gap to form a thermal insulation layer 3, and the inner wall of the inner pipe is sprayed with an anti-wear insulating material to form an anti-wear insulating layer 4 , the outer walls of both ends of the oil pipe body are provided with external threads, and are screwed with collars 5 to realize the connection between the two oil pipe units.

[0071] One or more centralizers (not shown) are set on the inner pipe. The centralizer can adopt the existing technology, which is ring-shaped, and several support points extend radially from the periphery, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com