Road and bridge fence protective guard structure

A technology for guardrails and bridges, applied to roads, bridges, roads, etc., can solve the problems of destroying family happiness, threats to people on board, casualties, etc., and achieve the effect of light and novel structure, novel connection structure and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

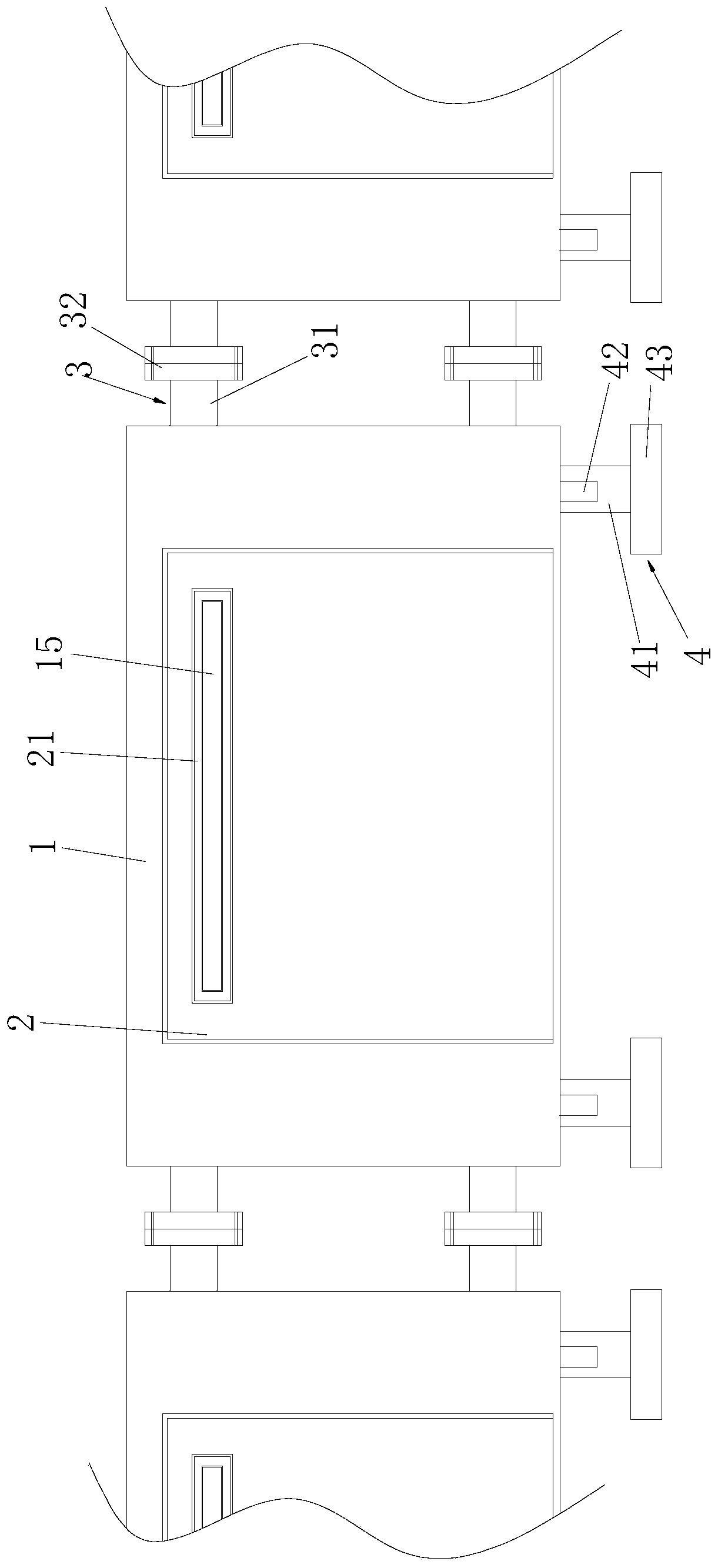

[0037] combine Figure 1 to Figure 4 , a road and bridge fence structure, including a plurality of buffer protection devices, the buffer protection device includes a main protection support 1 and a buffer main board 2, the front and rear ends of the main protection support 1 are fixedly connected with a plate connection assembly 3, the protection The lower end of the main support 1 is connected with a support frame 4 .

[0038] One side of the protective main support 1 is provided with a first support groove 11, and a first lifting horizontal plate 12 is arranged in the upper part of the first support groove 11, and the middle and lower parts of the first support groove 11 A first buffer mechanism 5 and a second buffer mechanism 6 are respectively provided. The upper part of the buffer main board 2 is provided with a first main board slot 21 , and the inner side of the middle part and the lower part of the buffer main board 2 are connected with a first moving post 22 and a se...

Embodiment 2

[0055] The above-mentioned road and bridge fence structure is provided with a new type of buffer protection device. The device is provided with a new type of protective main support 1 and a buffer main board 2, and between the main protective support 1 and the buffer main board 2 is firstly provided with a second The first buffer mechanism 5 and the second buffer mechanism 6 of the primary buffer. When the first buffer mechanism 5 and the second buffer mechanism 6 fail or the buffer effect weakens, the buffer sub-plate 15 pops up for secondary buffering.

[0056] When the car hits the guardrail, it will first crash into the buffer main board 2, and the second buffer spring and the fourth buffer spring compress to alleviate the impact on the buffer main board 2. When the impulse is too large, the first buffer spring and the third buffer spring are compressed to further reduce the impulse received by the buffer main board 2. Through the setting of the first buffer spring, the se...

Embodiment 3

[0058] When the impulse of the car to the buffer main board 2 exceeds the limit buffer capacity of the first buffer spring, the second buffer spring, the third buffer spring and the fourth buffer spring, when the buffer main board 2 moves to the position of the first upper extension block 721, The first upper protruding block 721 is inserted into the first lifting slot 121 .

[0059] Then the first upper protruding piece 721 squeezes the first lower protruding piece 731 into the inside of the first connecting rod longitudinal groove 711, and then the first internal compression spring 14 returns to its original length, and the first internal compression spring 14 compresses the first The limit connecting rod 71 and the buffer sub-plate 15 are pushed outward, and after the buffer sub-plate 15 contacts the hit vehicle and receives the force from the upper right side of the vehicle, part of the buffer sub-plate 15 is stuck in the groove of the second lifting plate 13, and there is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com