A pavement engraving machine

A technology of engraving and dust-absorbing mechanism, which is applied in the direction of roads, roads, road repairs, etc., can solve problems that affect the breathing health of construction workers, large gravel dust, polluted air environment, etc., to facilitate safe road construction and enhance processing capacity , the effect of avoiding additional damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

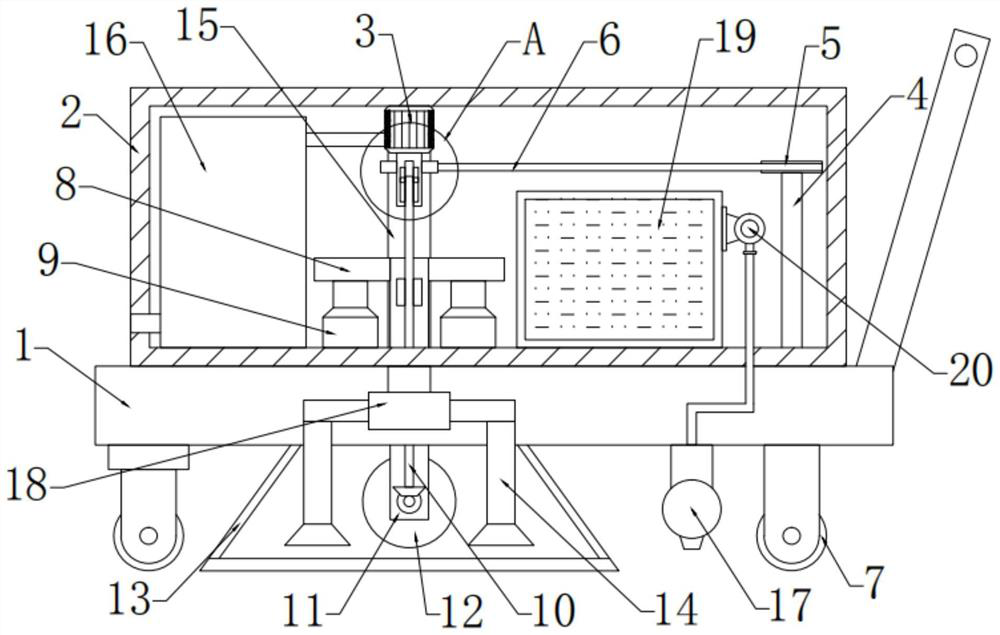

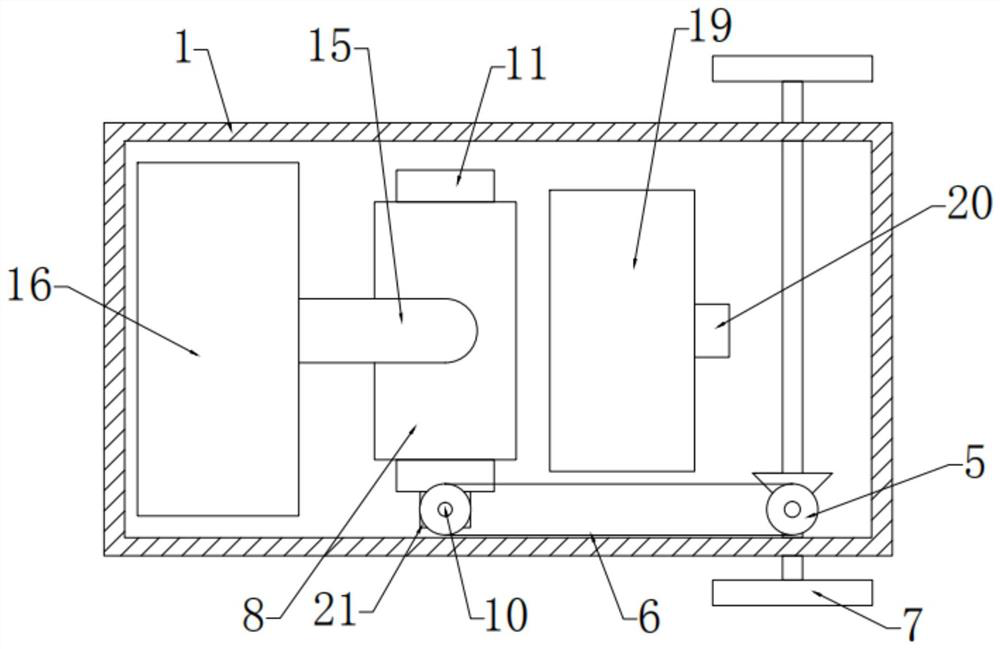

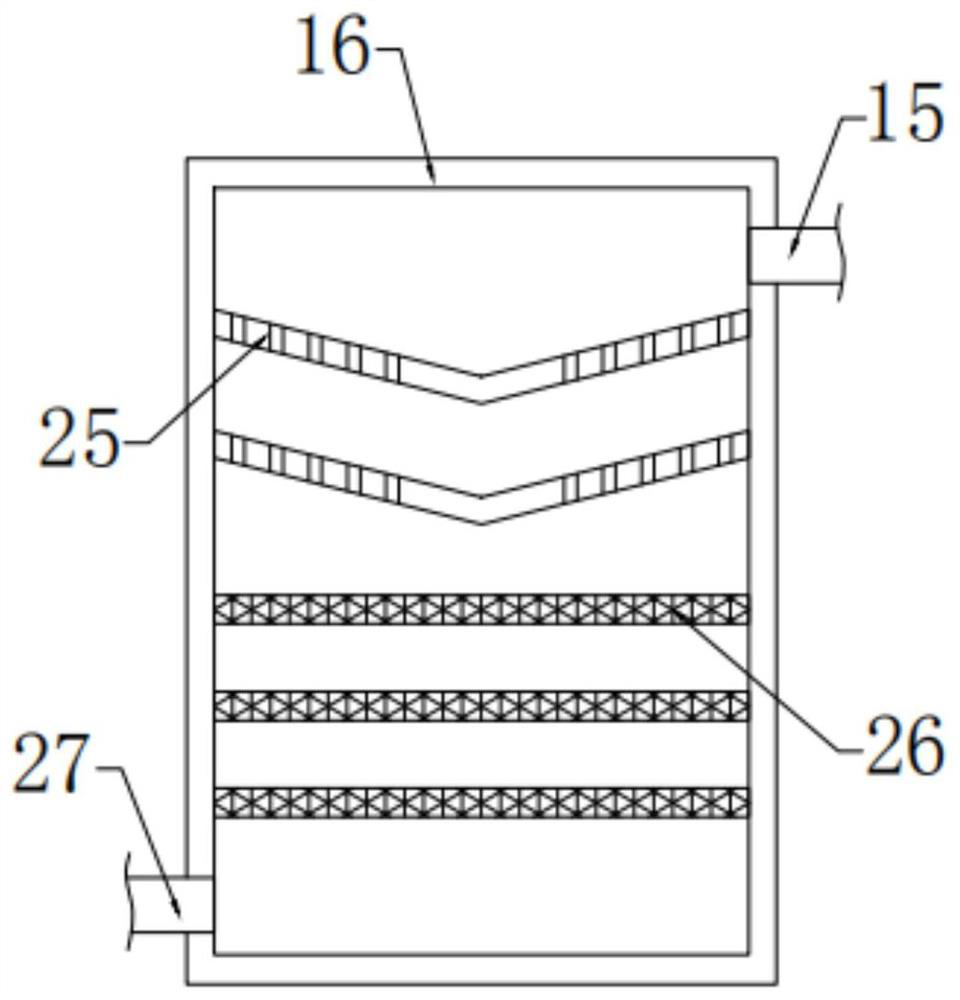

[0025] see Figure 1-4 , in an embodiment of the present invention, a road surface engraving machine includes a base plate 1, a housing 2 is fixedly connected to the top of the base plate 1, and an engraving mechanism is arranged on the inner side of the housing 2, and the left side of the engraving mechanism A dust suction mechanism is provided, and a dust reduction mechanism is provided on the right side of the engraving mechanism.

Embodiment 2

[0027] In this embodiment, the engraving mechanism includes an engraving roller 12 arranged on the lower side of the bottom plate 1, and a fixed plate 11 is arranged on the front and rear sides of the engraved roller 12, and the engraved roller 12 and the fixed plate 11 They are rotatably connected by a rotating shaft, and the rotating shaft is connected to the drive mechanism arranged inside the housing 2. The top of the fixed plate 11 is fixedly connected with a support plate 8, and the bottom end of the support plate 8 is fixed to the housing 2. The connection is provided with a telescopic rod 9.

[0028] In this embodiment, the drive mechanism includes a motor 3, the motor 3 is bolt-connected and arranged on the inner top of the housing 2, the output end of the motor 3 is fixedly connected to the fixed rod 22, and the inner side of the fixed rod 22 is slidably connected with a The rotating rod 10, the rotating rod 10 is located on the left and right sides of the inner part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com