Axial-flow fan blade high-flow glass fiber reinforced flame-retardant AS special material and preparation method thereof

A technology of flowing glass fiber and axial flow fan blades, which is applied in the field of plastics, can solve the problems of not being able to meet the use requirements of fan blades and the large amount of addition, and achieve the effects of stable mechanical properties, suitable fluidity, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described below with embodiment.

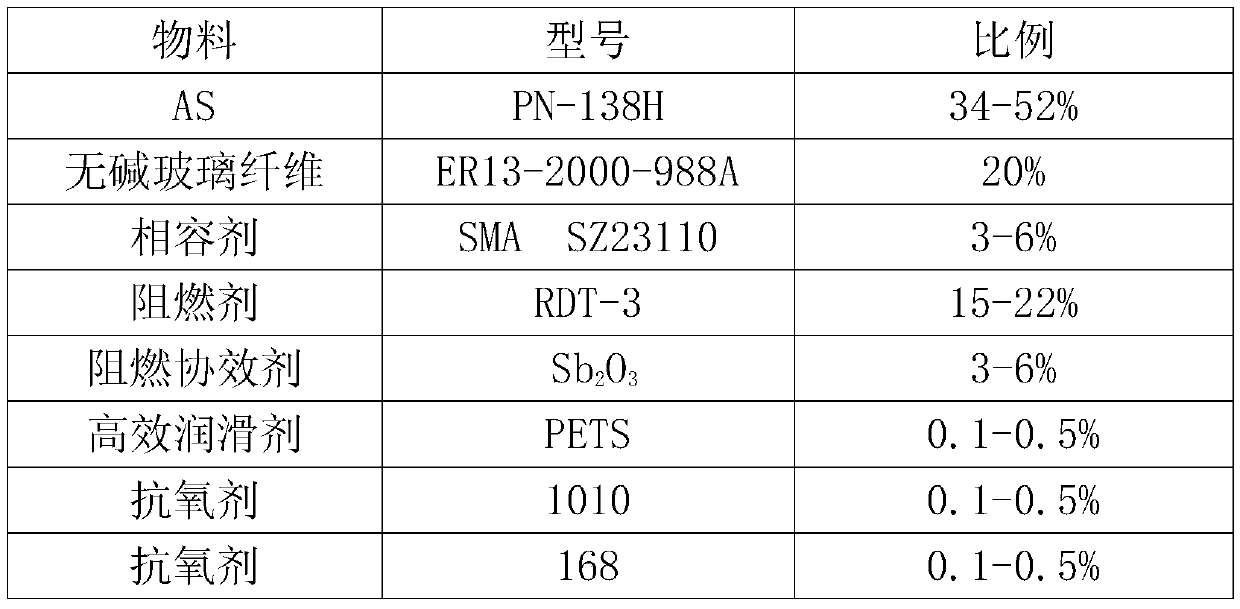

[0025] The high-flow glass fiber reinforced flame-retardant AS special material for axial-flow fan blades includes 34-52% of acrylonitrile-styrene copolymer, 20% of alkali-free glass fiber, 3-6% of compatibilizer, and flame retardant in percentage by weight. 15-22%, flame retardant synergist 3-6%, high-efficiency lubricant 0.1-0.5% and antioxidant 0.2-1%.

[0026] The surface of alkali-free glass fiber is coated with silane-based sizing agent; the compatibilizer is styrene-maleic anhydride copolymer.

[0027] The flame retardant is decabromodiphenylethane; the flame retardant synergist is antimony trioxide.

[0028] The high-efficiency lubricant is pentaerythritol stearate.

[0029] The antioxidants are tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester and phosphite.

[0030] Prescription of the present invention is as follows:

[0031]

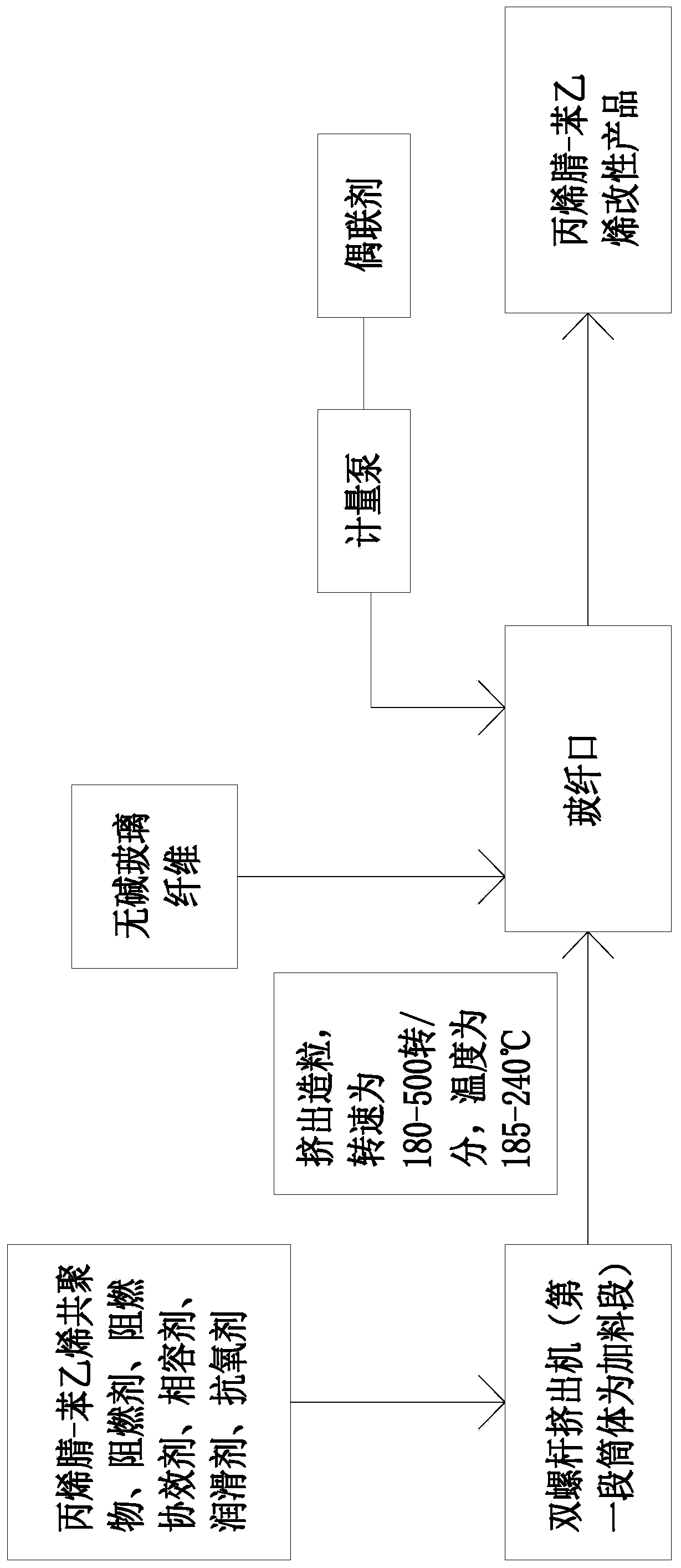

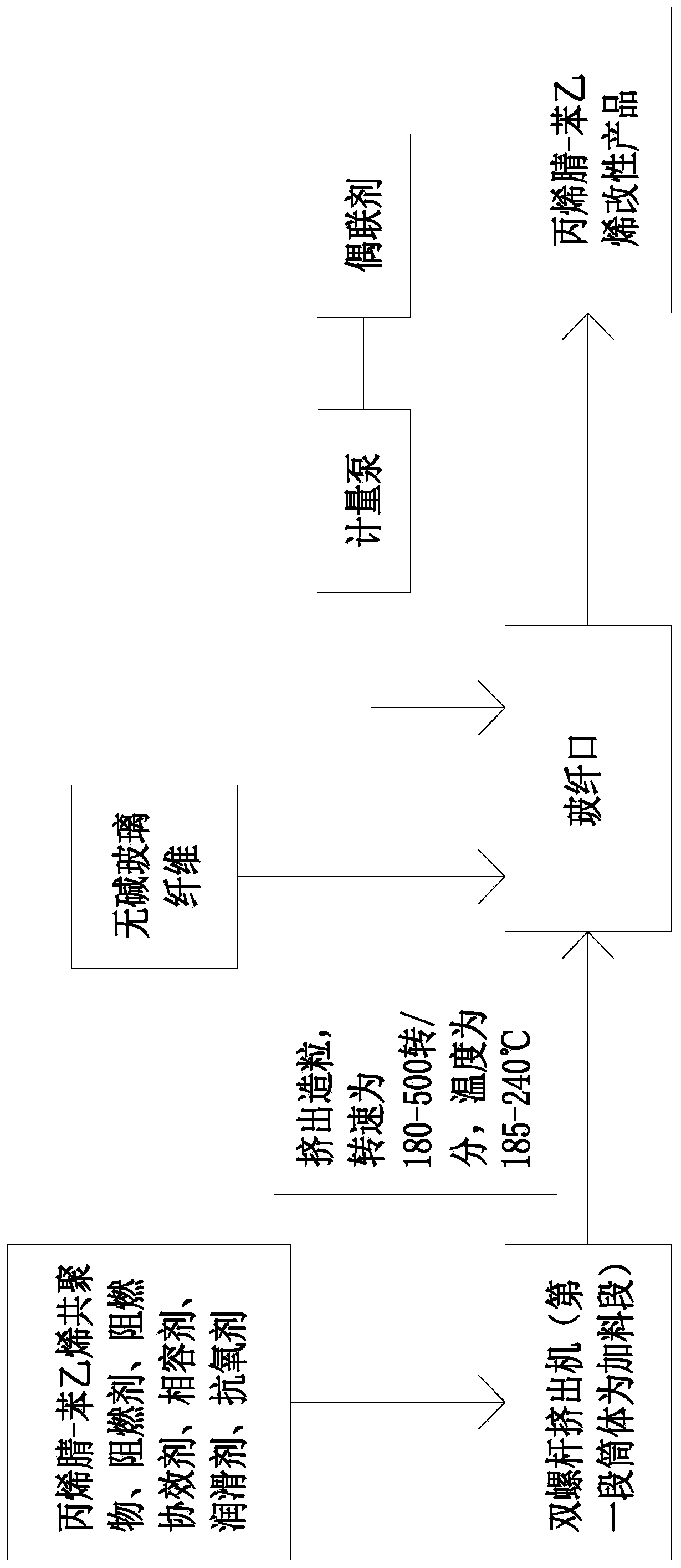

[0032] The method for prepari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com