A green production process of PVC type disposable gloves using water as medium

A green production, disposable technology, applied in gloves, clothing features, clothing, etc., can solve environmental pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

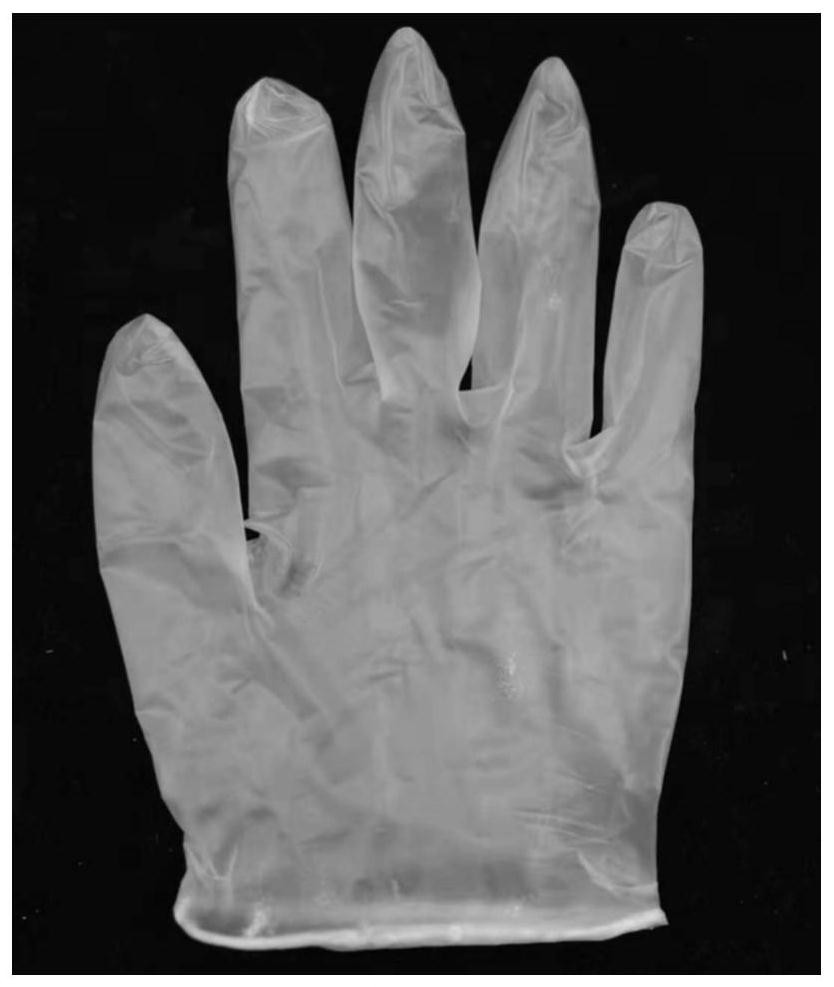

[0036] Embodiment 1: PVC gloves are prepared by plasticizing after swelling first

[0037] (1) The trade mark that present embodiment adopts PVC particle is TPH-31, and nonionic emulsifier is nonylphenol polyoxyethylene ether (TX-4), and plasticizer is dioctyl terephthalate (DOTP), will 100 parts of PVC particles, 4 parts of TX-4 and 160 parts of water are mixed and dispersed to obtain a dispersion of PVC particles containing an emulsifier in water;

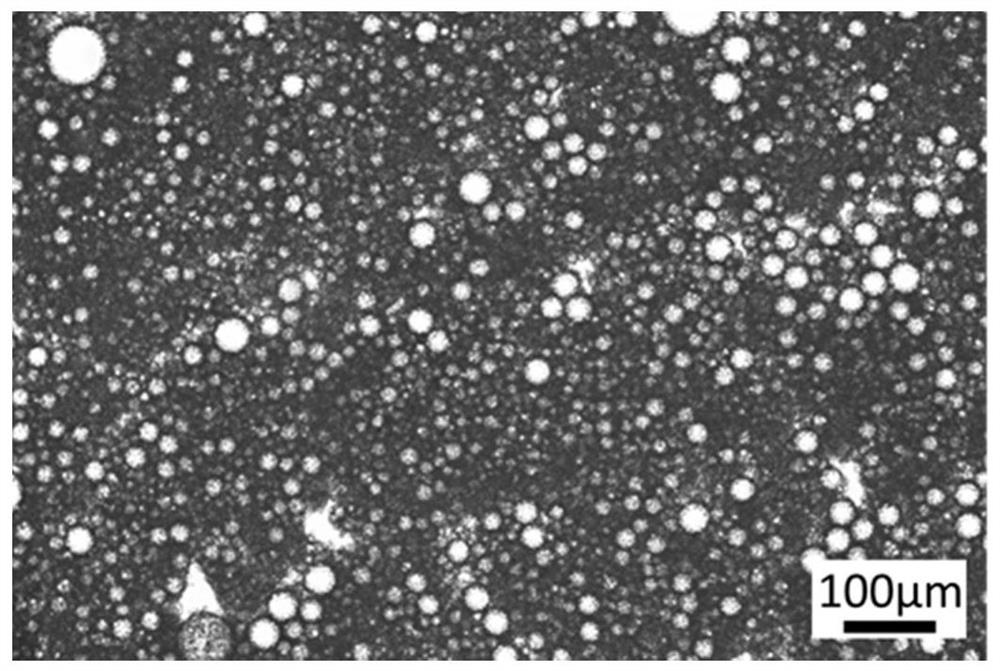

[0038] (2) Add 70 parts of DOTP to the PVC dispersion generated in step (1), start to stir and disperse the DOTP on the upper layer, and mix at a low speed to high speed to disperse the stirring to obtain a PVC paste resin emulsion, such as figure 1 As shown, the circular area is the emulsion, the interior of the emulsion is DOTP plasticizer, and the PVC particles gathered at the boundary appear black;

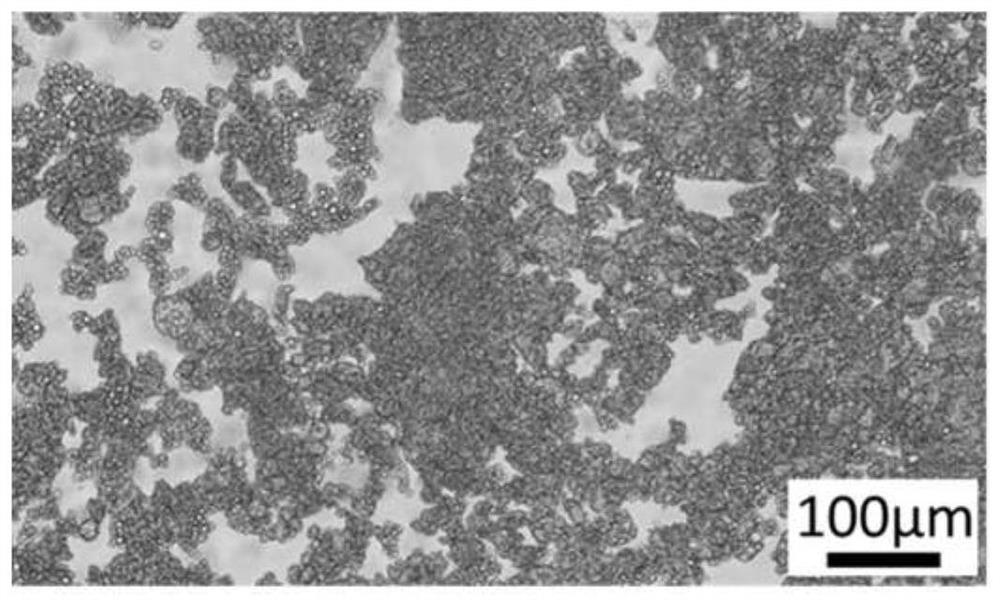

[0039] (3) Stir the emulsion generated in step (2) at a temperature of 40°C with a rotation speed of 70rpm for 6 hours at a slo...

Embodiment 2

[0043] Embodiment 2: Adjust DOTP to prepare PVC gloves with different properties

[0044] (1) The trade mark that present embodiment adopts PVC particle is TPH-31, and nonionic emulsifier is nonylphenol polyoxyethylene ether (TX-4), and plasticizer is dioctyl terephthalate (DOTP), will 100 parts of PVC granules, 4 parts of TX-4 and 160 parts of water are mixed and dispersed to obtain a dispersion of PVC granules containing emulsifiers in water. Repeat the above steps to obtain another two parts of the same PVC granules containing emulsifiers dispersion in water;

[0045] (2) Add 50 parts, 70 parts, and 90 parts of DOTP to the three parts of PVC particle dispersion generated in step (1) respectively, and start stirring to disperse the DOTP in the upper layer, and mix at a low speed to high speed. Get PVC paste resin emulsion;

[0046] (3) Stir the three parts of emulsions generated in step (2) at a temperature of 40° C. at a slow speed of 70 rpm for 6 hours at the same time, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap