Oil well cement composition and application thereof

A technology of oil well cement and composition, which is applied in the field of exploration and development of oil and gas fields, can solve the problems of high cost of micropearl cement slurry, limited space for ash storage on site, and inability to realize full sealing, etc., and achieves reduced curing time, simple composition, and easy construction. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

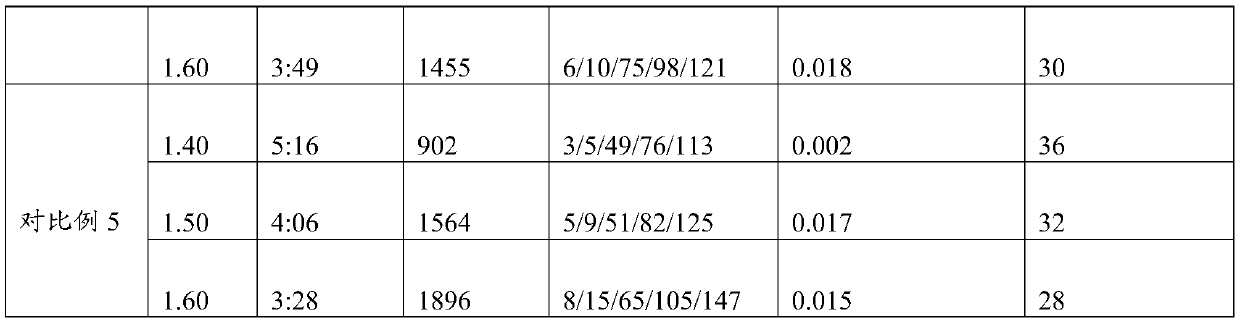

Examples

Embodiment 1

[0048] In this embodiment, various raw materials are taken in parts by weight to prepare an oil well cement composition.

[0049] Mix 100 parts of G grade oil well cement, 15 parts of cement kiln dust, 3 parts of lithium carbonate, 10 parts of calcium oxalate, 8 parts of superfine material, and 5 parts of expansion agent to form an oil well cement composition. Prepare the above oil well cement composition with appropriate amount of water, fluid loss reducer, retarder and defoamer according to the cement slurry preparation method specified in GB / T 19139-2012 "Oil Well Cement Test Methods" 1.40g / cm 3 , 1.50g / cm 3 and 1.60g / cm 3 Three densities of grout. In this embodiment, the ultrafine material is a mixture of ultrafine calcium carbonate and ultrafine calcium hydroxide with a weight ratio of 70:30; the expansion agent is a mixture of α hemihydrate gypsum and magnesium oxide with a weight ratio of 60:40.

Embodiment 2

[0051] In this embodiment, various raw materials are taken in parts by weight to prepare an oil well cement composition.

[0052] Mix 100 parts of G-grade oil well cement, 30 parts of cement kiln dust, 1 part of sodium aluminate, 15 parts of sodium sulfate, 5 parts of superfine material, and 1 part of expansion agent to form an oil well cement composition. Prepare the above oil well cement composition with appropriate amount of water, fluid loss reducer, retarder and defoamer according to the cement slurry preparation method specified in GB / T 19139-2012 "Oil Well Cement Test Methods" 1.40g / cm 3 , 1.50g / cm 3 and 1.60g / cm 3 Three densities of grout. Ultrafine material ultrafine calcium carbonate in the present embodiment; Expansion agent is the mixture of dihydrate gypsum and magnesium oxide that the weight ratio is 55:45.

Embodiment 3

[0054] In this embodiment, various raw materials are taken in parts by weight to prepare an oil well cement composition.

[0055] Mix 100 parts of G-grade oil well cement, 20 parts of cement kiln dust, 5 parts of anhydrous sodium metasilicate, 15 parts of sodium sulfate, 5 parts of superfine material, and 2 parts of expansion agent to form an oil well cement composition. Prepare the above oil well cement composition with appropriate amount of water, fluid loss reducer, retarder and defoamer according to the cement slurry preparation method specified in GB / T 19139-2012 "Oil Well Cement Test Methods" 1.40g / cm 3 , 1.50g / cm 3 and 1.60g / cm 3 Three densities of grout. In this embodiment, the ultrafine material is ultrafine calcium oxide; the expansion agent is magnesium oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com