Multi-functional dust-raising-prevention vertical type stone edge grinding machine

An anti-dust and multi-functional technology, applied in machine tools, grinders, mechanical equipment and other directions suitable for grinding the edge of workpieces, can solve the problems of grinding machinery damage and stone edge damage, etc. effect, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

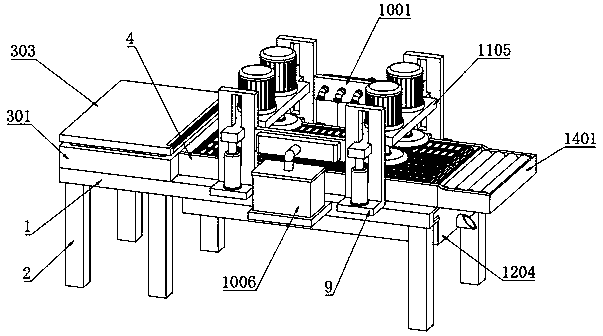

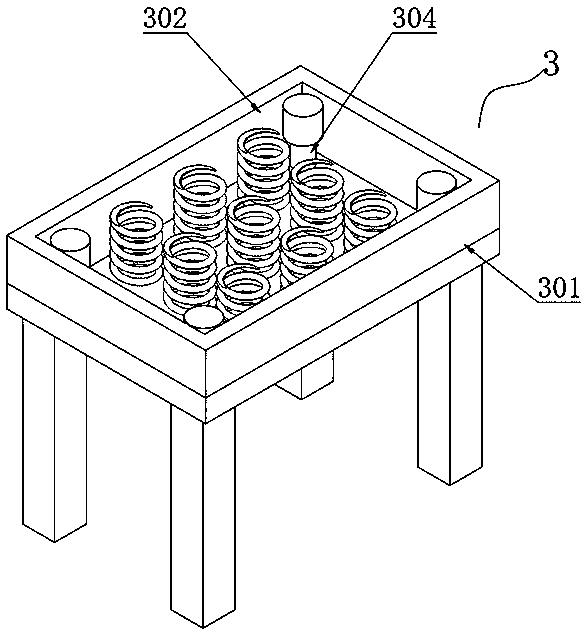

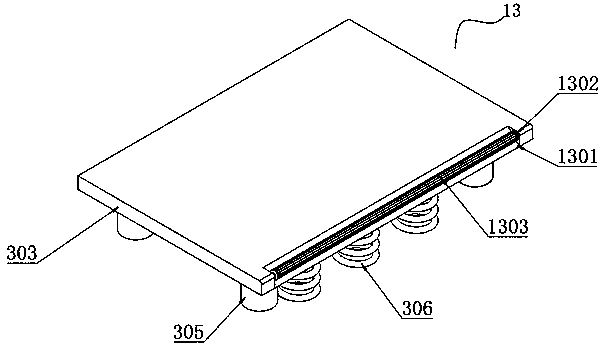

[0045] Example: such as Figure 1-7 As shown, the present invention provides a technical solution, a multi-functional dust-proof vertical stone edging machine, including an edging table 1, and stable pillars 2 are fixedly installed at each corner of the bottom end of the edging table 1. A buffer mechanism 3 is installed on one side of the side platform 1, and the buffer mechanism 3 includes a support platform 301, a buffer chamber 302, a pressure bearing plate 303, a limit guide rod 304, a limit sleeve 305 and a buffer spring 306;

[0046] A support platform 301 is fixedly installed on one side of the edging platform 1, and a buffer chamber 302 is provided inside the support platform 301. The inner side of the buffer chamber 302 is located at the top of the support platform 301, and a pressure plate 303 is embedded and connected. The buffer chamber 302 Limiting guide rods 304 are fixedly installed at each corner of the inner side, and limit sleeves 305 are installed at the fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com