Steel pipe welding device

A technology for welding devices and steel pipes, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of high stability requirements for welding guns, high physical exertion of operators, uneven welding quality, etc., and improve the level of And stability, improve welding efficiency, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

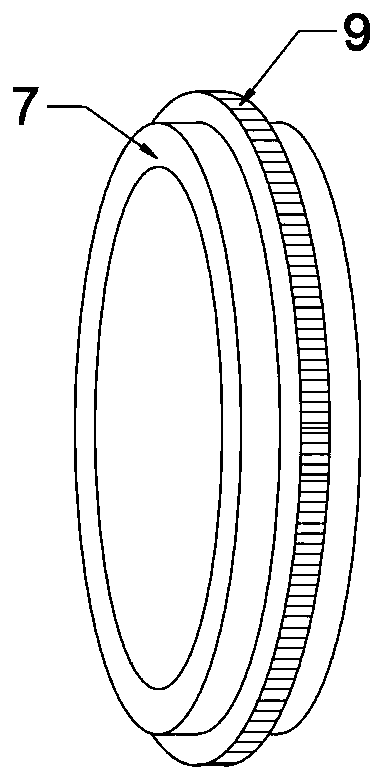

[0020] see Figure 1-4 , in an embodiment of the present invention, a steel pipe welding device includes a housing 1, a welding mechanism and a clamping mechanism; the housing 1 is a hollow box structure with openings on both sides, and a rotating drum is arranged inside the housing 1 7. The drum 7 is a hollow cylinder with openings at both ends. A welding mechanism is provided on the drum 7. The welding mechanism includes a set of welding guns 2 arranged oppositely. The upper end is nested with a chute plate 4, the chute plate 4 is provided with a radial chute, and the radial chute is provided with a screw 5, the screw 5 runs through the lifting frame 3 and is threadedly connected with the lifting frame 3; The rod 5 extends to the outside of the chute plate 4, and the end of the screw rod 5 is fixedly connected with a runner 6; the inside of the chute plate 4 is fixedly connected with a drum 7, and the drum 7 is connected with a fixed frame 8 through a bearing sleeve, and the...

Embodiment 2

[0022] The difference between this embodiment and Embodiment 1 is that: the two sides of the drum 7 are provided with a clamping mechanism, and the clamping mechanism includes two groups of symmetrically arranged clamping plates 12 distributed up and down, and the clamping plates 12 are arc-shaped plates. It can better fit the steel pipe surface; the clamping plate 12 is fixedly connected with a sliding block 13, and the housing 1 is provided with a chute frame 14 that cooperates with the sliding block 13, and the chute frame 14 is fixedly connected with the inner wall of the housing 1 , the chute frame 14 is provided with a vertical chute, the vertical chute is provided with a two-way screw mandrel 15, the two-way screw mandrel 15 is rotationally connected with the vertical chute inner wall, the two-way screw mandrel 15 runs through the sliding block 13, and the two-way screw mandrel 15 It is threadedly connected with the sliding block 13; the upper end of the housing 1 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com