Axial force online detection device for working roller of four-roller strip rolling mill

A detection device, axial force technology, applied in the direction of length measuring device, metal rolling, manufacturing tools, etc., can solve the problems of lack of direct clarity, signal lag, etc., and achieve the effect of quick connection and disconnection, and good correspondence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

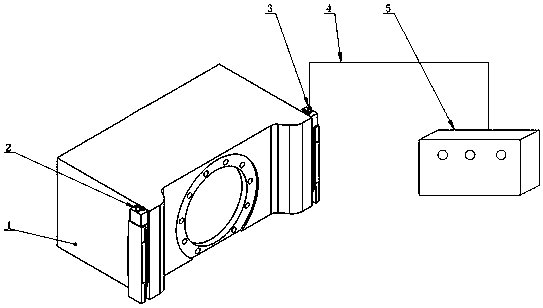

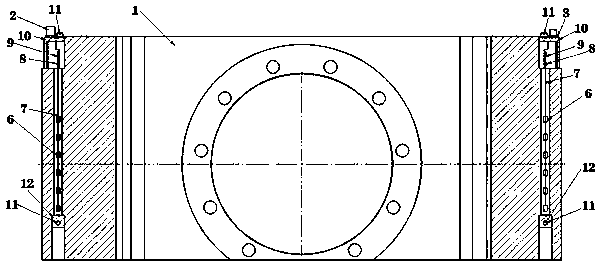

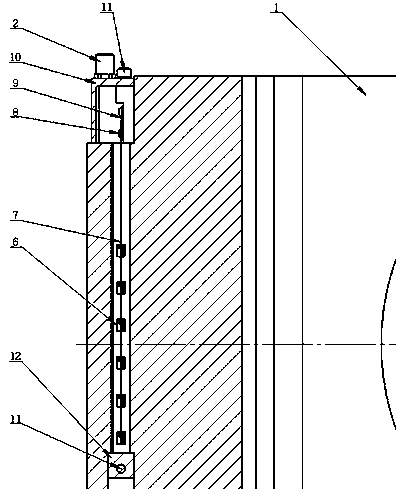

[0027] According to attached figure 1 to attach Figure 9 As shown, the bearing seat 1, the quick connector 3, the strain gauge 6, the circuit board 9 and the protective cover 13; the two ends of the bearing seat 1 are provided with flanges, and the strain gauges 6 are installed on the flanges to convert the axial force signal into bending Torque stress signal, the stress signal is output through the circuit board 9; a protective cover 13 is arranged outside the detection device, and a quick connector 3 is arranged at the signal output terminal. The detection device of the present invention is designed based on the inherent axial restraint structure in the work roll system, and the flange part of the bearing housing 1 in the axial restraint structure is used as the force-bearing body for signal detection. The structure of the detection device is design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com