System for automatic cleaning and automatic detection of auto parts

A technology for auto parts and automatic cleaning, which is applied in the direction of cleaning methods, cleaning methods and utensils, and sorting using gas flow, which can solve the problems of high cost and inapplicability, achieve convenient operation, save time, and improve clean production capacity The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

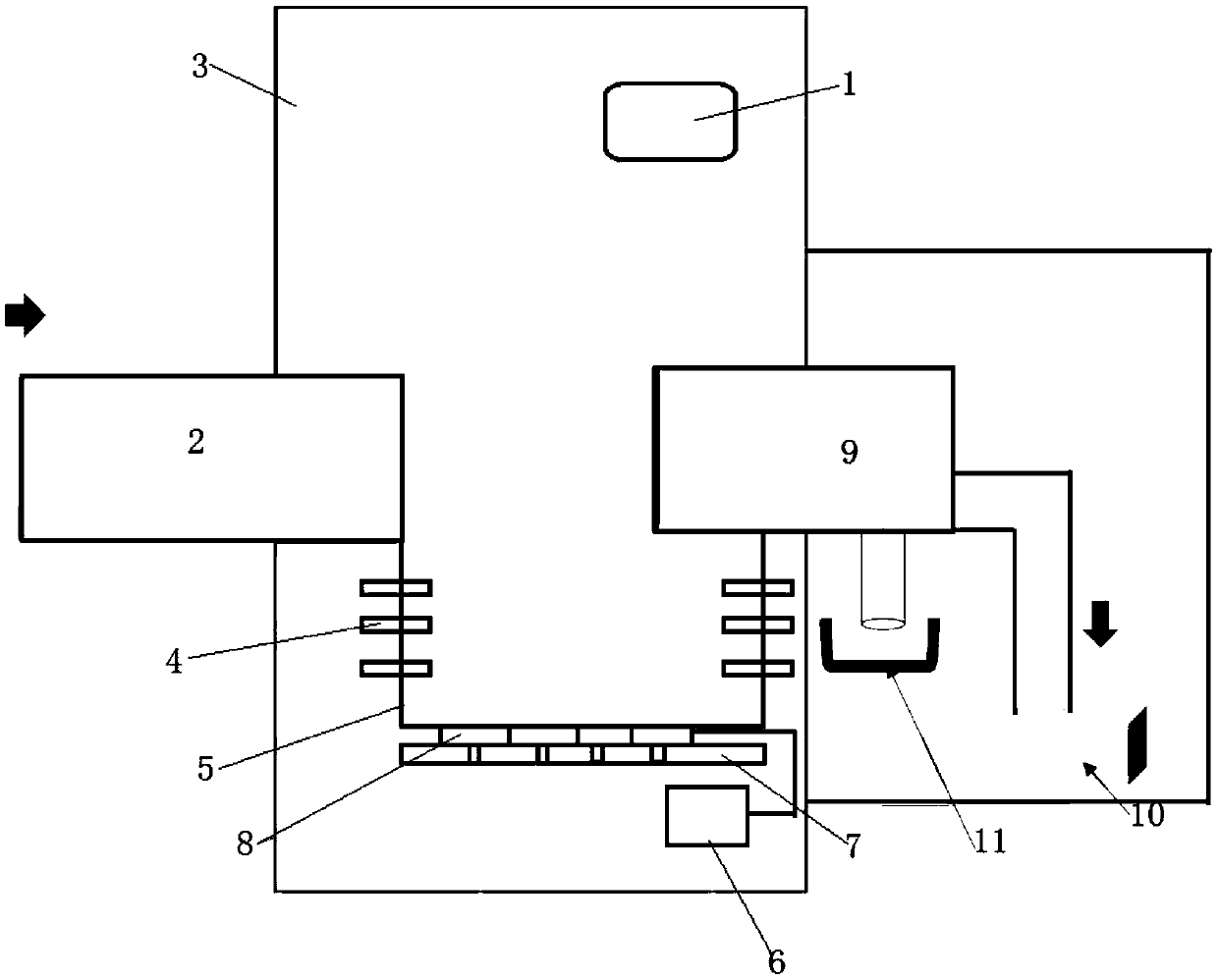

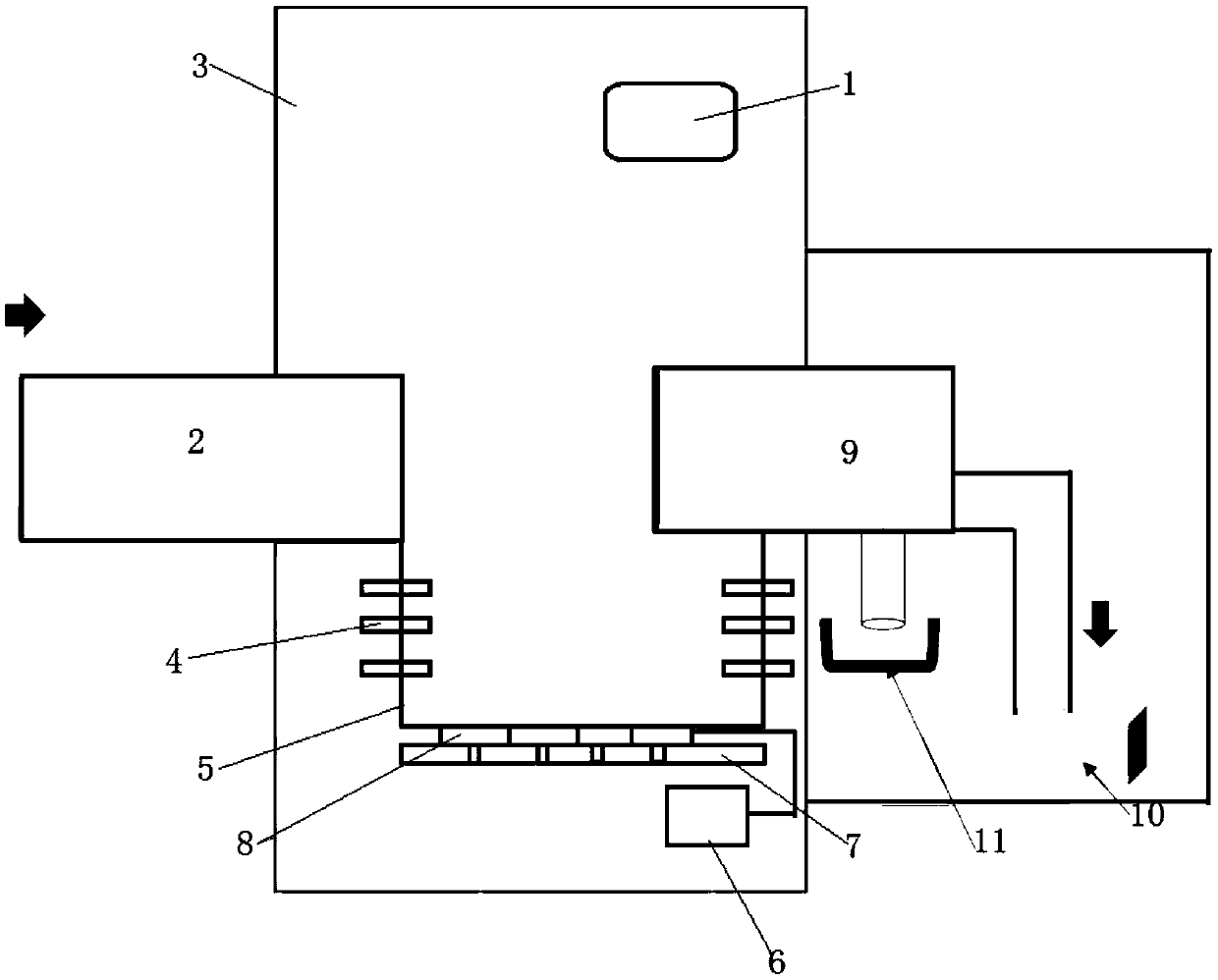

[0041] refer to figure 1 , a system for automatic cleaning and automatic detection of auto parts, including an automatic product conveying tank 2, a cleaning storage tank 5, an air blowing device 4, a dust suction device 6 and a product output detection guide groove 9, and the product automatic conveying tank 2 is used for Transport the auto parts to the cleaning storage tank 5, and the air blowing device 4 is arranged on the side wall of the cleaning storage tank 5, and is used to clean the dust and impurities on the surface of the auto parts products by blowing air, that is, to realize the cleaning of the auto parts products by blowing air Effect, the dust suction device 6 is arranged at the bottom of the cleaning storage tank 5, and is used to collect and discharge the dust and impurities blown off the surface of the auto parts product, and the product output detection guide groove 9 is used to detect the cleaned auto parts product, Identify qualified products and unqualifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com