Welding type probe, intelligent bolt and assembly process thereof

A technology of intelligent bolt and assembly process, applied in the direction of screws, measuring devices, connecting components, etc., can solve the problems of destroying the strength of bolts, difficult processing, unfavorable for mass production, etc., to reduce production costs, low processing difficulty, and beneficial to The effect of mass production and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

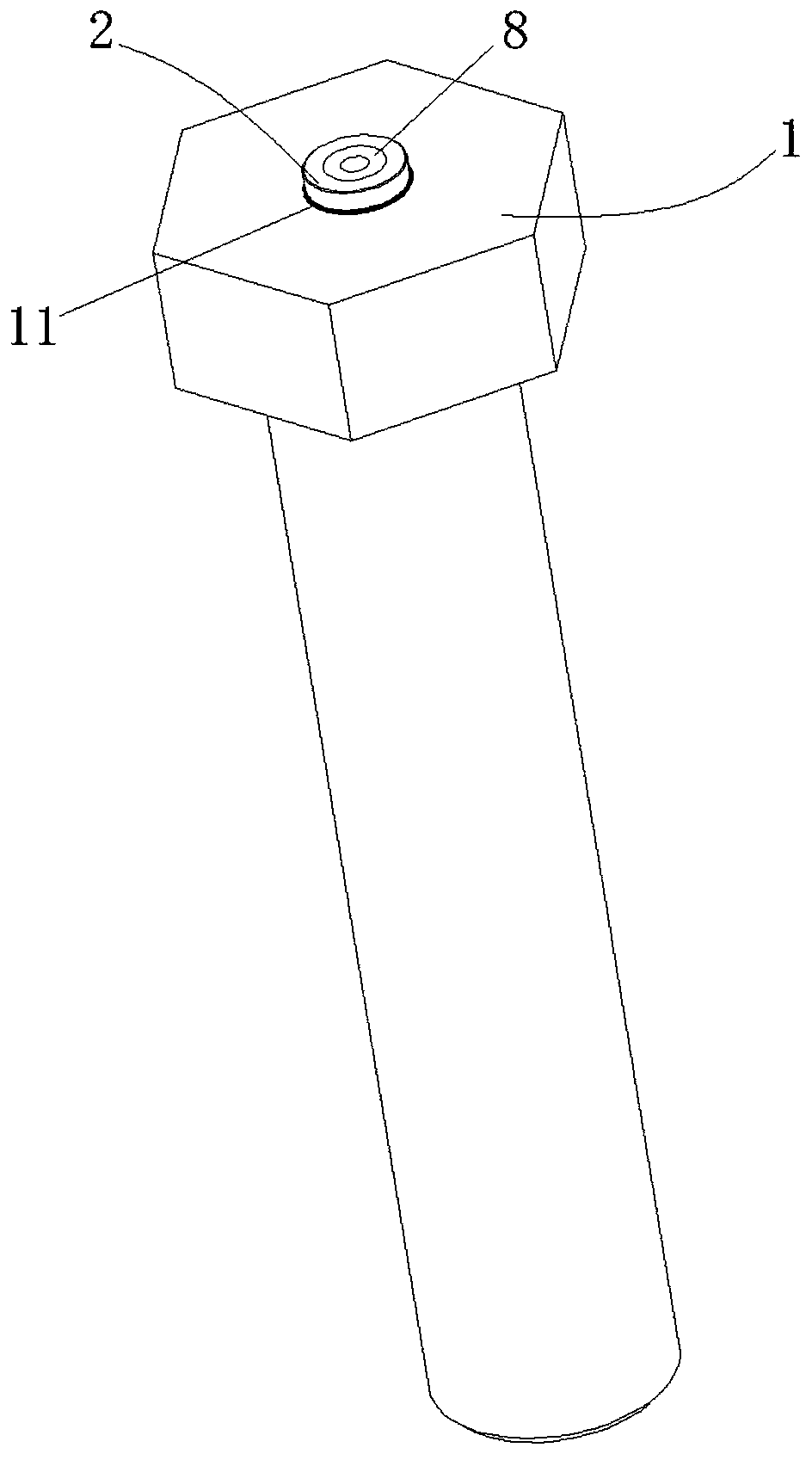

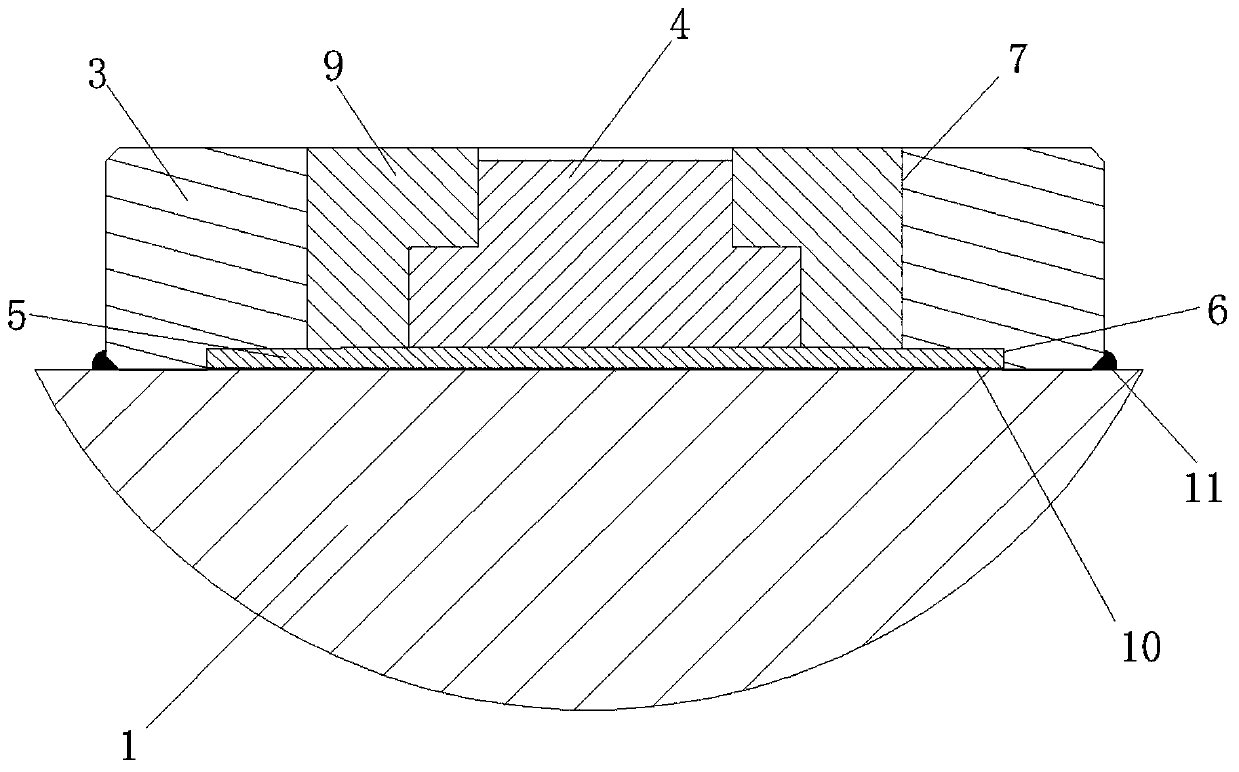

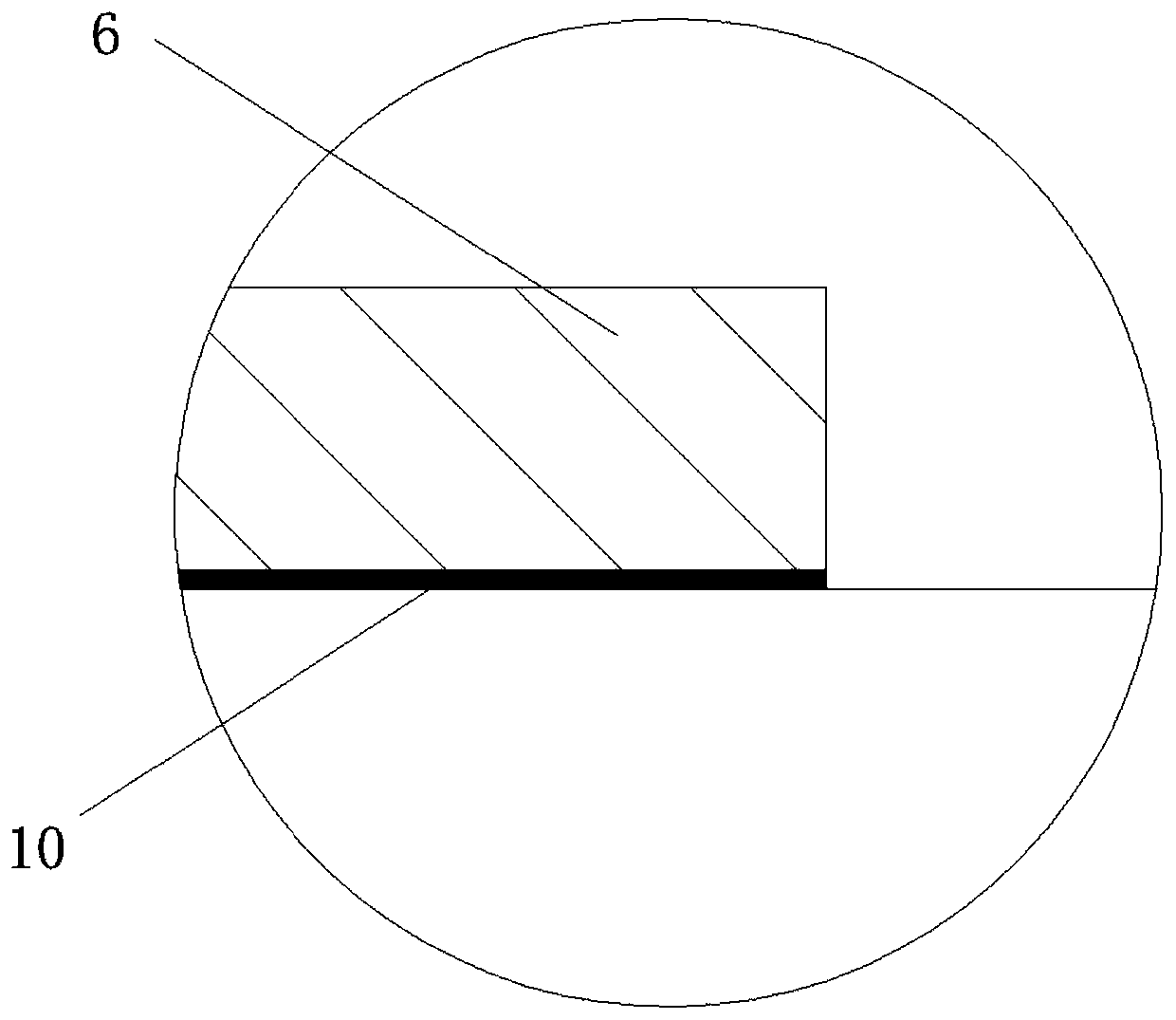

[0029] Such as Figure 1-3 As shown, the welded probe includes a sheath 3, a contact 4 and a wafer 5. The sheath 3 is also provided with a mounting groove 6 and a through hole 7. The wafer 5 is inserted into the mounting groove 6. The upper surface of the wafer 5 is connected to the sheath 3. An insulating film is provided, and the insulating film is used to insulate and firmly connect the upper surface of the wafer 5 and the sheath 3, the contact 4 is located in the through hole 7, and the contact 4 is fixedly connected to the wafer 5, and the contact 4 is connected to the sheath 3. There is a gap 8 filled with a damping layer 9 for insulating the contact 4 from the sheath 3 , the upper surface of the wafer 5 is electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com