Lower shell assembly for refrigerator compressor

A technology for refrigerator compressors and components, which is applied to pump components, mechanical equipment, variable-capacity pump components, etc. It can solve problems such as poor fixation of shell components, overheating of internal parts of the compressor, and affecting the overall operation of the compressor. Achieve the effect of preventing poor heat dissipation, prolonging service life, and good anti-corrosion and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

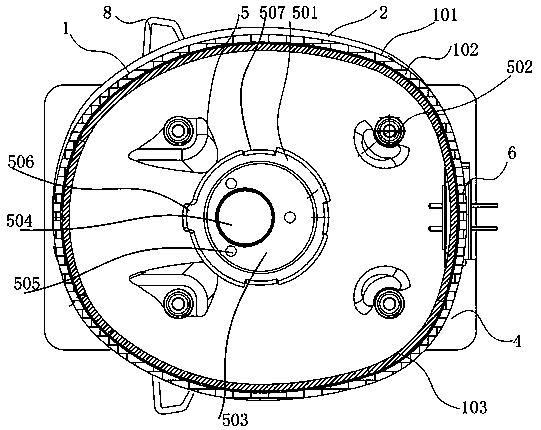

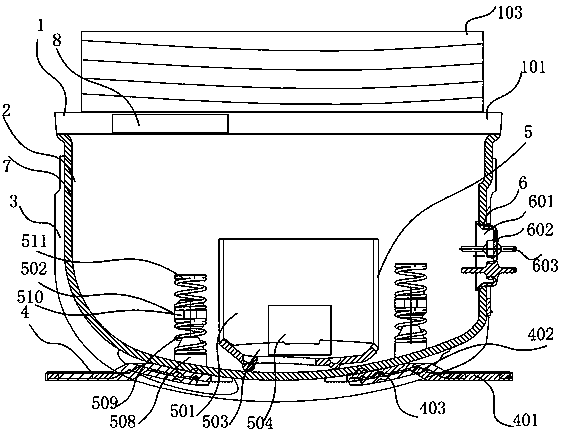

[0018] A lower shell assembly for a refrigerator compressor, comprising a positioning top ring seat assembly 1, a shell body assembly 2, a reinforced protective support 3, a positioning support plate assembly 4, an elastic positioning assembly 5, and a heat dissipation unit assembly 6. The shell body assembly 2 The top is provided with a positioning top ring seat assembly 1 and connected by welding. The inner end of the shell body assembly 2 is bonded with a sound-absorbing and shock-absorbing layer 7. The outer wall of the shell body assembly 2 is welded with a reinforced protective support 3. The positioning support The plate component 4 runs through the through hole on the reinforced protective support 3 and extends inward to the bottom of the shell body component 2. The positioning support plate component 4 is welded to the shell body component 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com