Glass bottle arranging, detecting, alarming and automatic processing device

A technology for automatic processing and glass bottles, which is applied in the direction of conveyor control devices, transportation and packaging, conveyors, etc., can solve the problem of low efficiency of the arrangement of the arrangement mechanism, and achieve the effect of improving the arrangement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

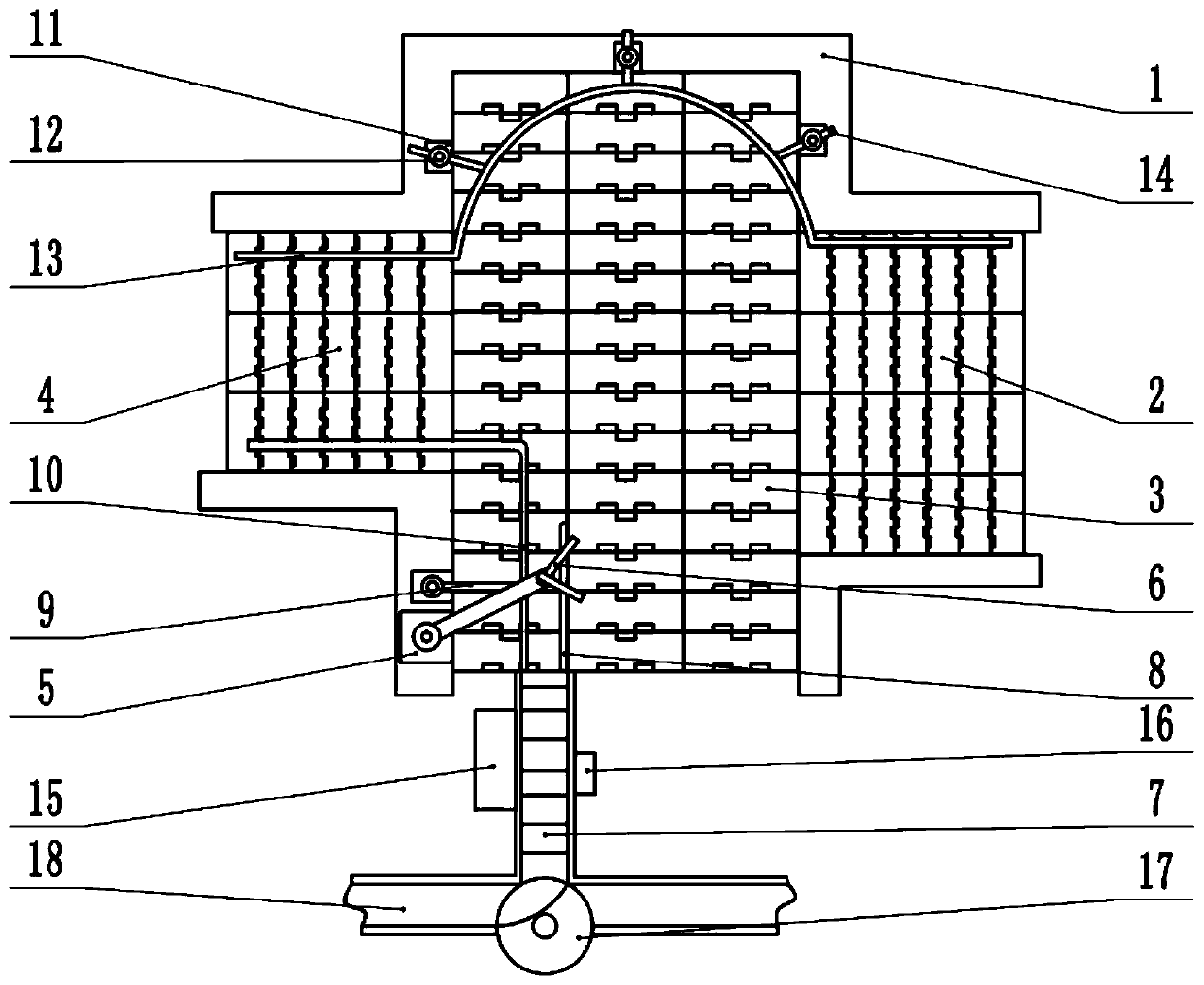

[0025] The reference signs in the accompanying drawings of the description include: frame 1, input conveyor belt 2, transverse feed belt 3, temporary stop conveyor belt 4, arrangement support frame 5, adjustment plate 6, conveyor belt 7, main guide plate 8, fixed rod 9, Auxiliary guide plate 10, steering bracket 11, adjustment column 12, steering bar 13, adjustment rod 14, luminescent panel 15, photosensitive sensor 16, turntable 17, collection channel 18.

[0026] The embodiment is basically as attached figure 1 As shown: the glass bottle arrangement detection alarm and automatic processing device, including a frame 1, and the frame 1 is fixedly connected with an arrangement mechanism, a detection mechanism and a processing mechanism.

[0027] Wherein the arrangement mechanism includes an input conveyor belt 2, on which thirty glass bottles can be conveyed side by side at the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com