Liquid tank truck and anti-wave plate assembly thereof

A technology for a wave-proof board and a liquid tank truck, applied in the field of liquid tank trucks, can solve the problems of poor wave-proof effect of the wave-shaped wave-proof board, large assembly and welding stress, and low strength of the dish-shaped wave-proof board, so as to eliminate the risk of cracking. , The effect of improving impact resistance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Typical embodiments that embody the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

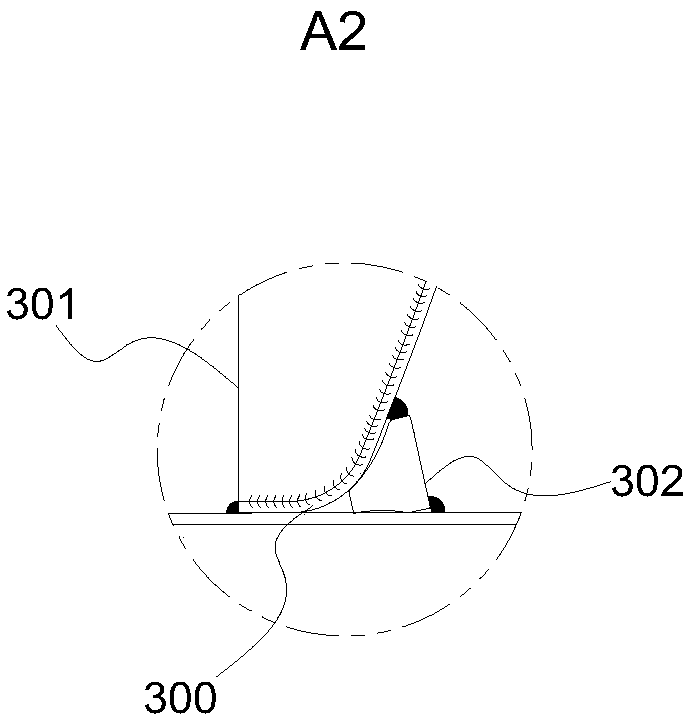

[0026] This embodiment provides a new anti-wave plate assembly. By combining the respective advantages of the above traditional wave-shaped anti-wave boards and dish-shaped anti-wave boards, a wave-proof board structure with high strength and good anti-wave effect is formed.

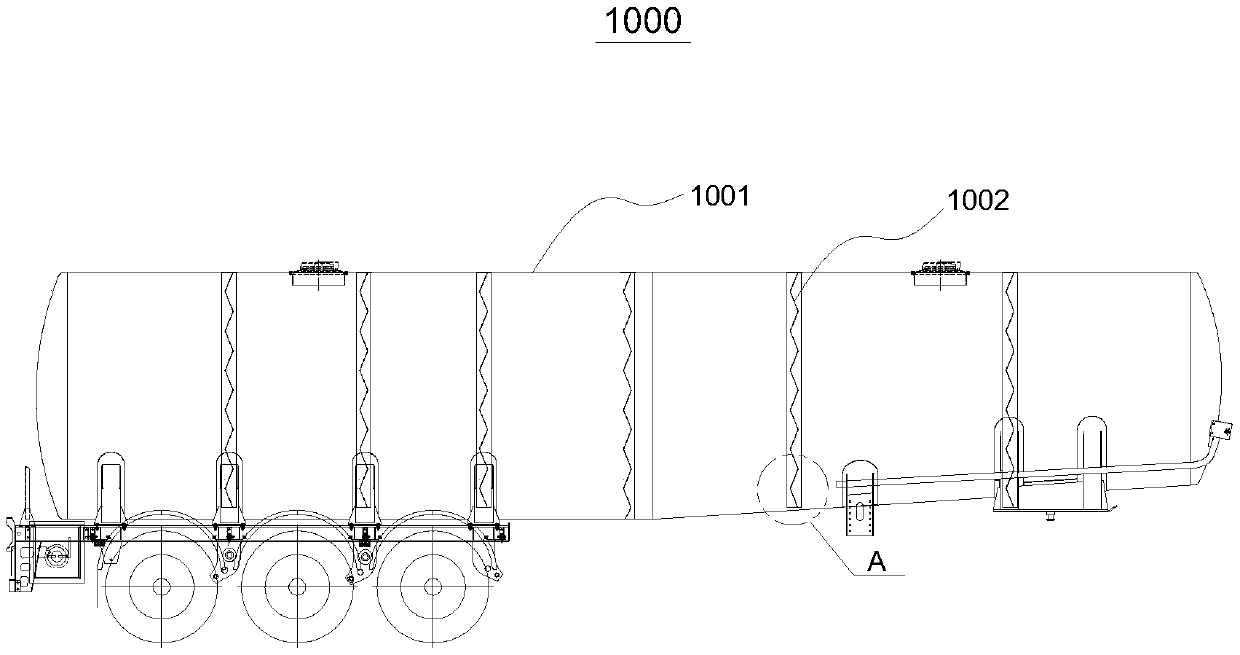

[0027] This embodiment also provides a liquid tank truck equipped with multiple sets of anti-wave plate assemblies.

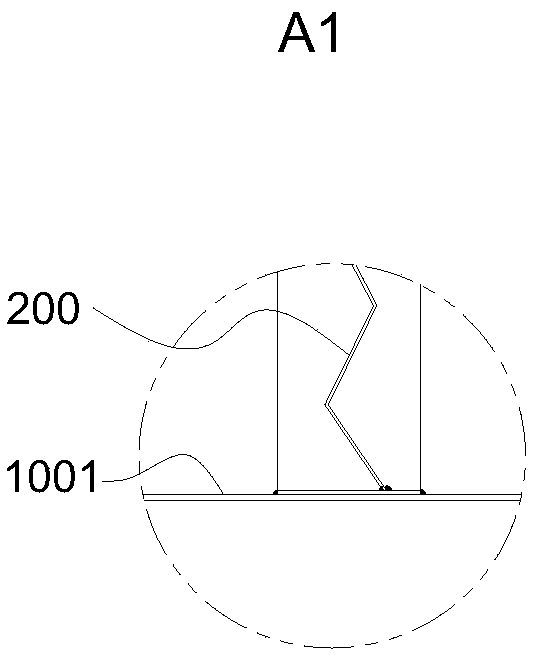

[0028] image 3 It is a schematic structural diagram of a liquid tank truck 1000, and the body of the liquid tank truck 1000 is provided with a tank body 1001 plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com