Cold shrink outdoor terminal pre-molding mixing device

A terminal and pre-mixing technology, which is applied in the field of mixing devices before molding, can solve problems such as material sticking, incomplete discharge, and mixing red interference, etc., and achieve the effects of low equipment cost, reduced usage, and strong energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

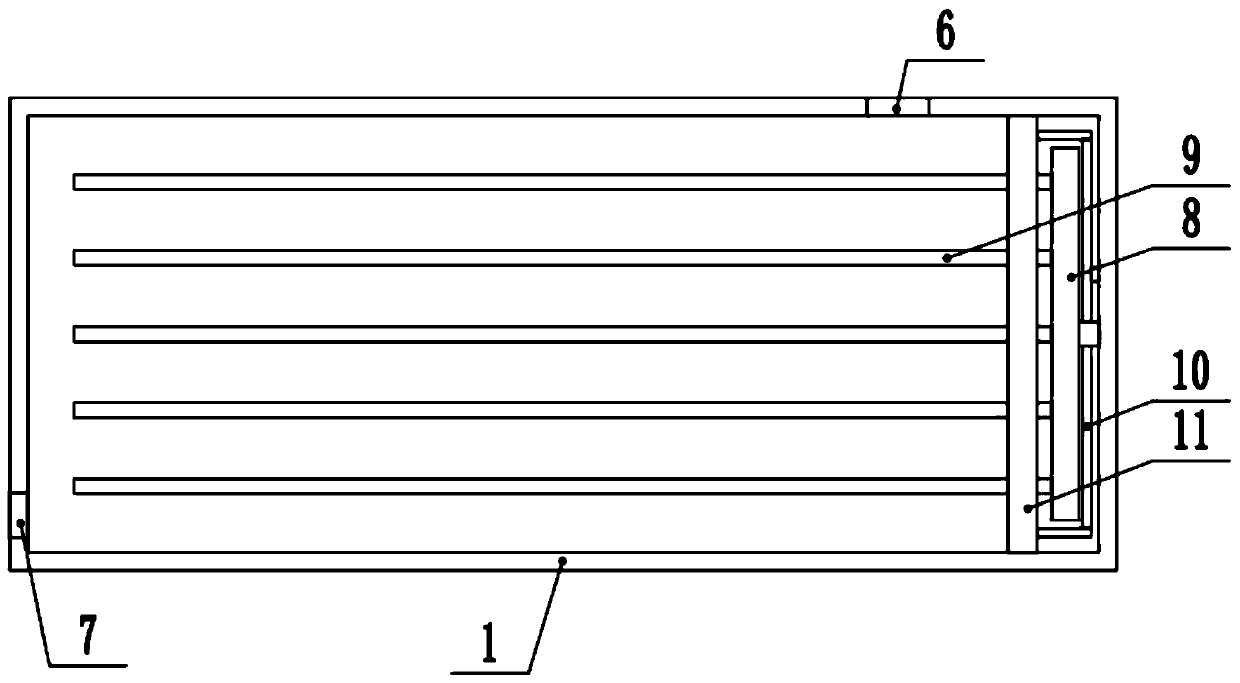

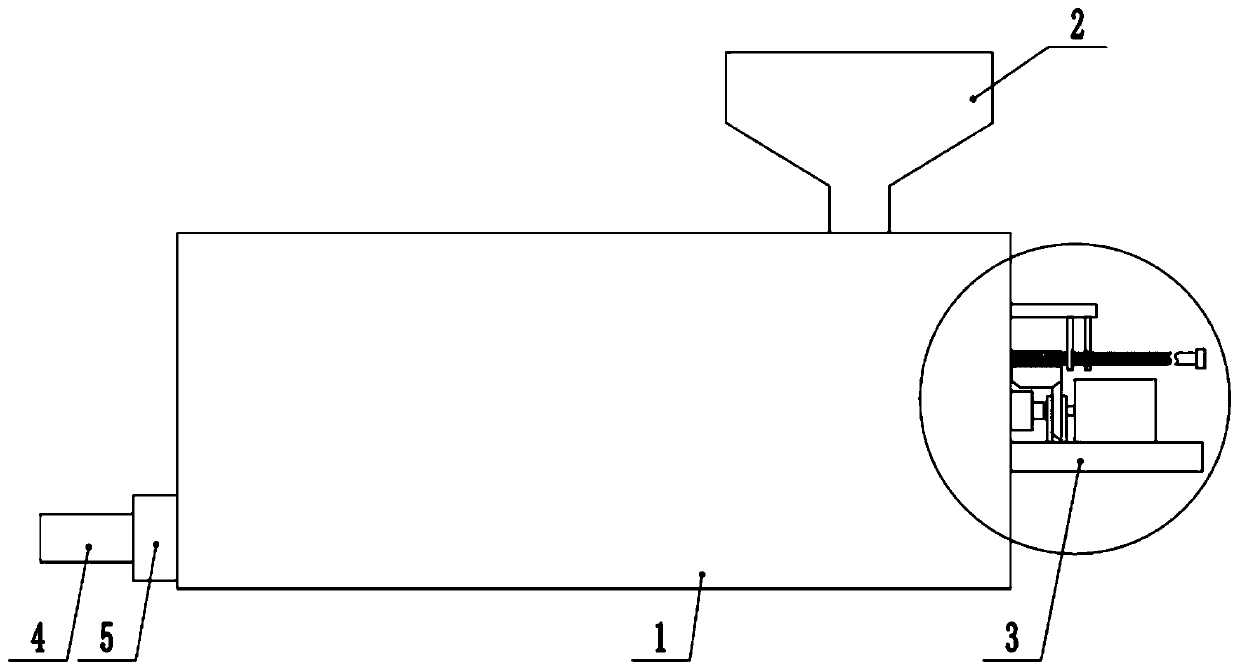

[0028] see Figure 1-5 , a pre-molding mixing device for cold-shrinkable outdoor terminals, including a mixing box 1, one end of the top of the mixing box 1 is fixedly connected to a feed hopper 2, and the mixing box 1 is provided with a stirring mechanism and a pushing mechanism, One end outside the mixing box 1 is provided with a driving device 3 for driving the stirring mechanism and the pushing mechanism, and the end of the mixing box 1 away from the driving device 3 is fixedly connected to the discharge pipe 4, and the discharge pipe 4 is provided with The discharge valve 5, the top and the side of the mixing box 1 are respectively provided with a feed inlet 6 and a discharge outlet 7 corresponding to the feed hopper 2 and the discharge pipe 4.

[0029] The stirring mechanism includes a turret 8 arranged at one end of the mixing box 1 , and one side of the turret 8 is fixedly connected with a plurality of stirring rods 9 .

[0030] The pushing mechanism includes a push p...

Embodiment 2

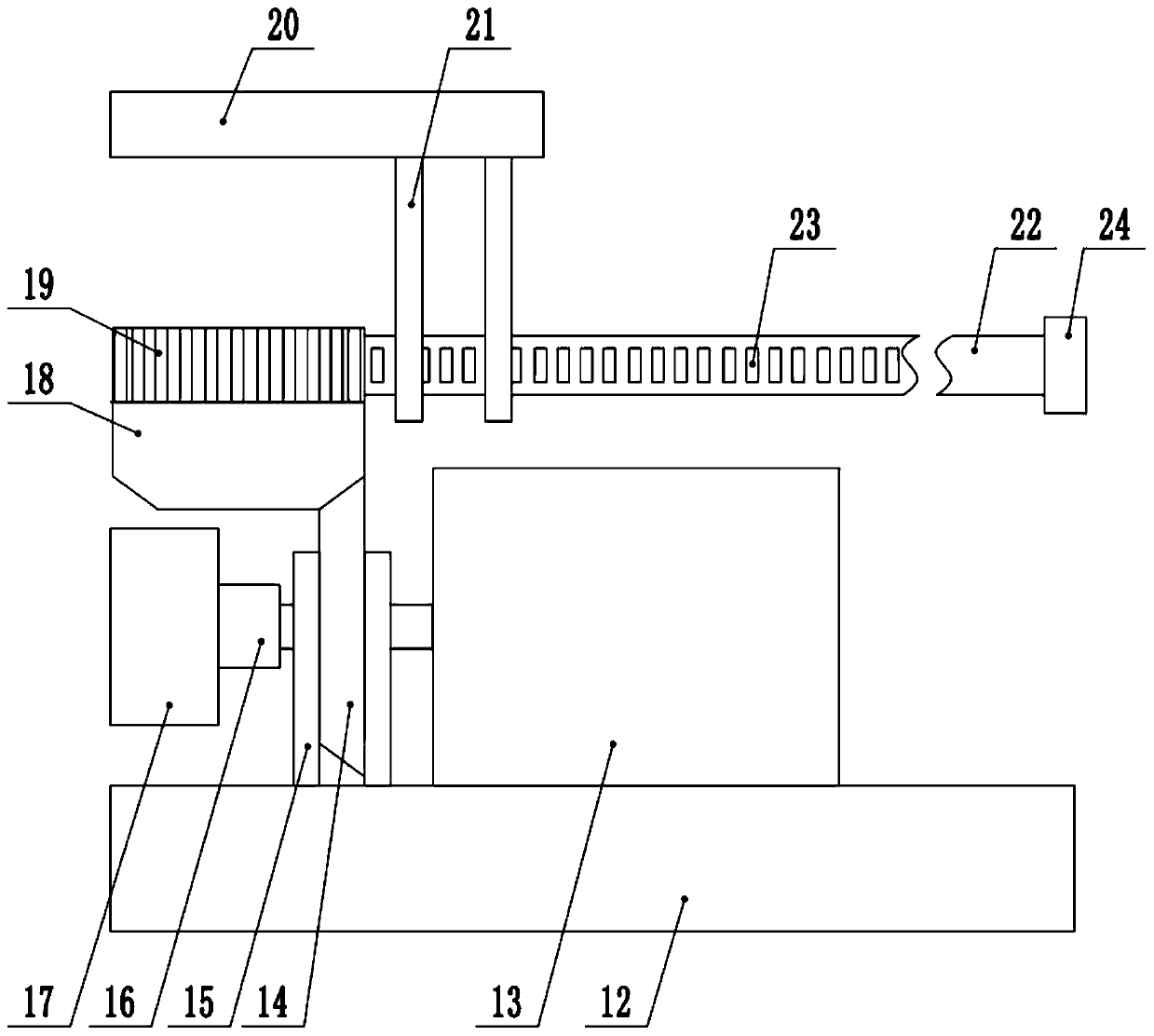

[0035] see Figure 1-5, the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the end of the mixing box 1 above the fixed seat 12 is fixedly connected to the top fixed seat 2012, and the bottom end of the top fixed seat 2012 is fixedly connected to a plurality of fixed plate 21 , the moving rod 22 runs through the fixed plate 21 . One end of the moving rod 22 away from the pushing frame 10 is fixedly connected to a limit end block 24 .

[0036] In the implementation process of the present invention, the material is first poured into the mixing box from the feed hopper 2, and then the driving motor is started, and the driving motor drives the locking device 17 outside the fixed sleeve 16 to rotate, so that the stirring rod inside the mixing box 1 9 Rotate to stir the material. After the stirring is completed, control the locking device 17 in the first cone wheel 14 to lock, and the drive motor 13 drives the first cone wheel 14 to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com