Double-sided laser marking mechanism for rapid automatic model changing of cylindrical products

A laser marking and cylindrical technology, applied in the field of laser marking, can solve the problems of difficult adjustment, time-consuming, error-prone, etc., and achieve the effect of improving efficiency and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

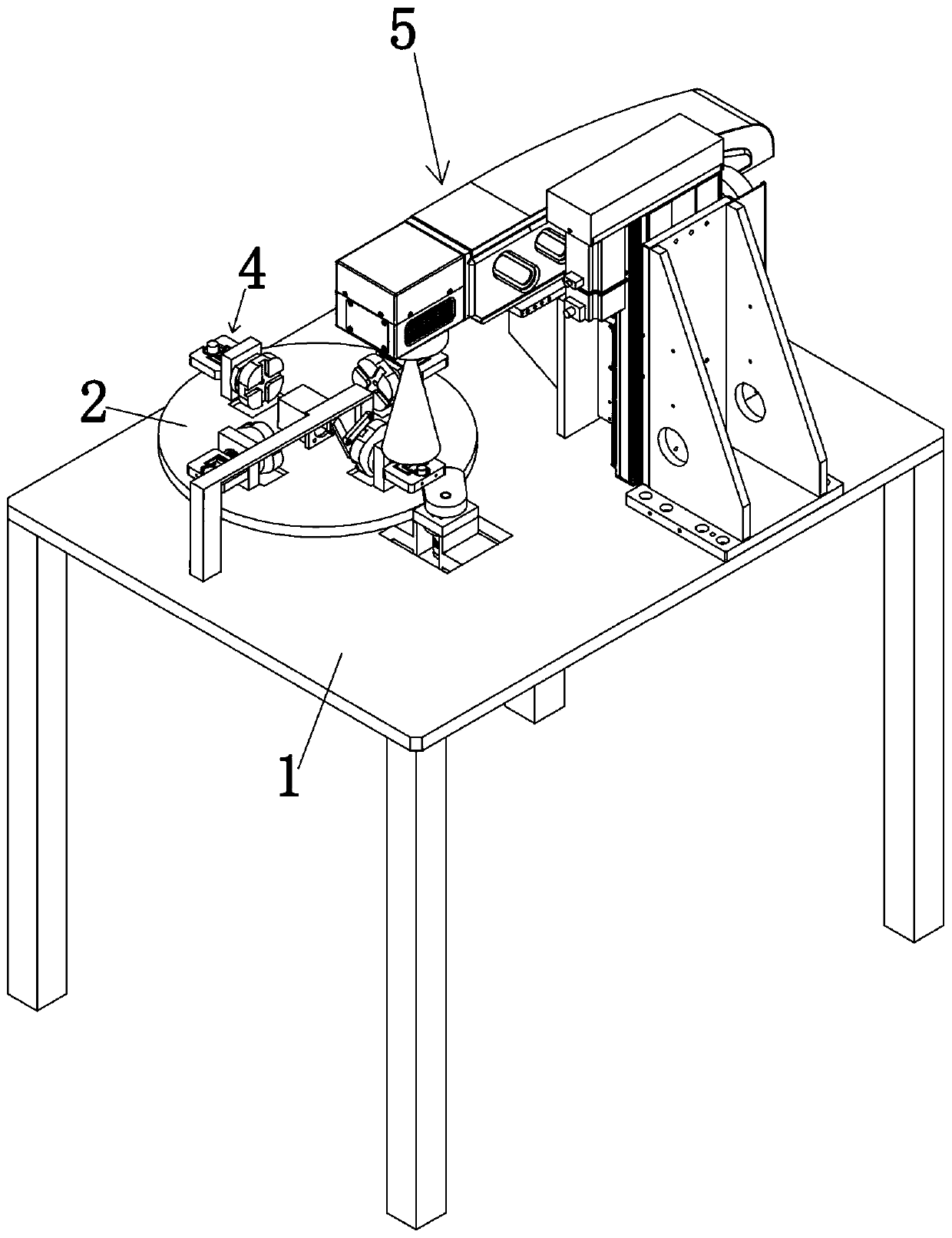

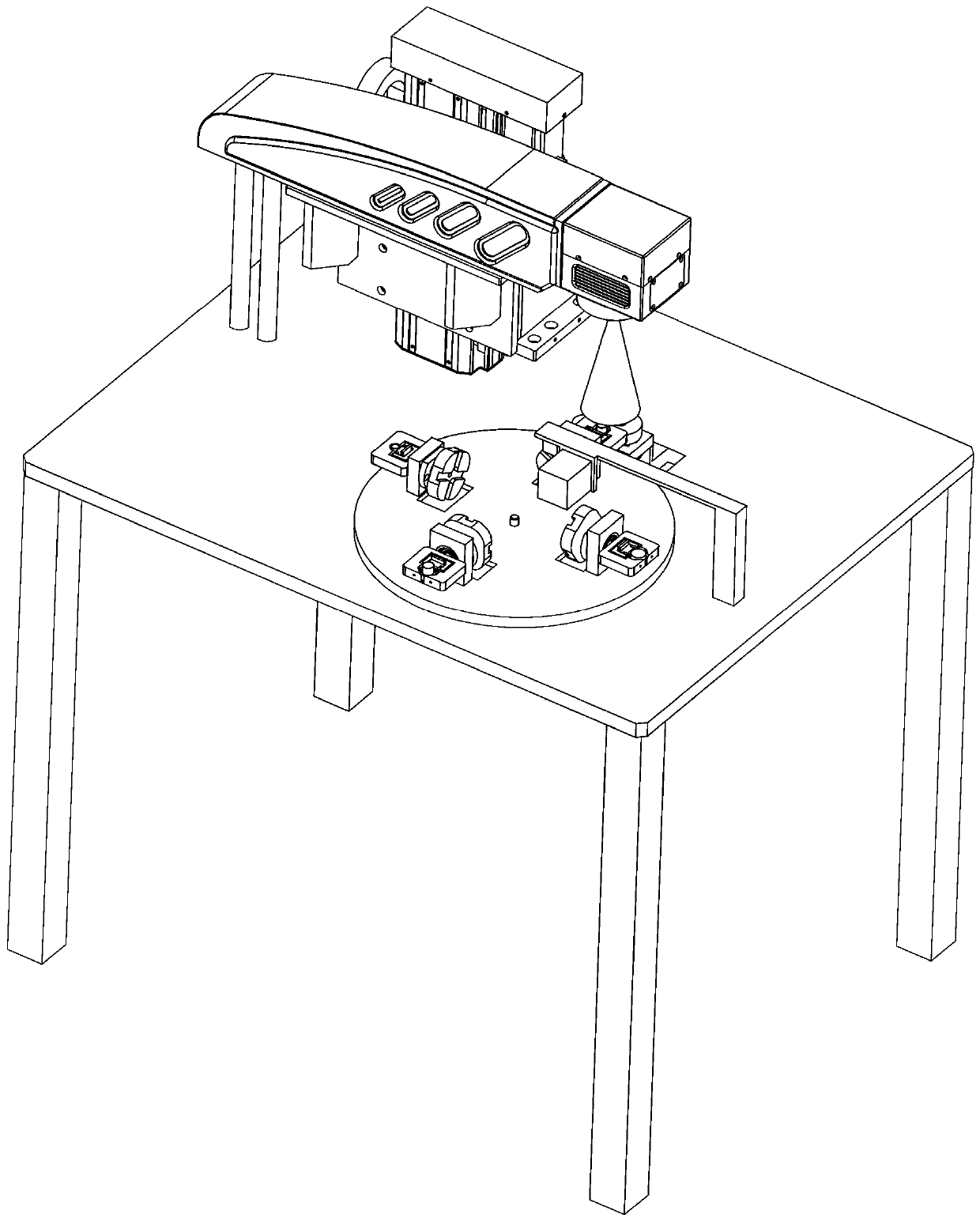

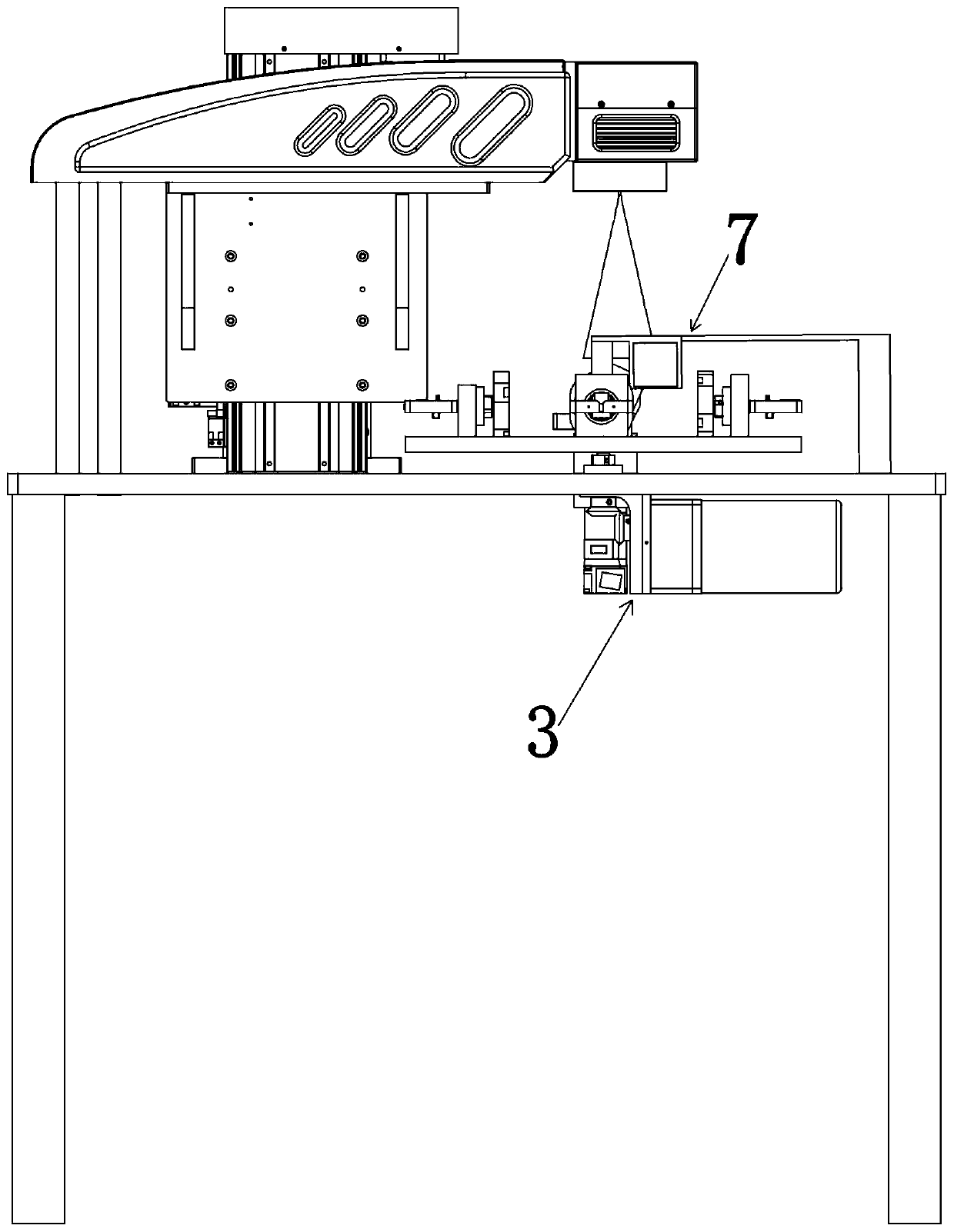

[0030] see Figure 1-18 As shown in the figure, a double-sided laser marking mechanism for fast and automatic type changing of cylindrical products includes a base 1, and a horizontally arranged turntable 2 is rotatably connected to the base 1, and is installed on the base 1. A power assembly 3 that drives the turntable 2 to rotate; the turntable 2 is provided with a plurality of flip positioning carriers 4 for clamping products of different specifications at intervals with its center as the center; The marking assembly 5 for marking the product in the flipping and positioning carrier 4; the base 1 is provided with an opening and closing assembly 6 below the marking assembly 5 for controlling the loosening or clamping of the flipping and positioning carrier 4; the The base 1 is provided with an inversion assembly 7 for controlling the rotation of the inversion positioning carrier 4 .

[0031] The power assembly 3 includes a reduction motor 31, a first bevel gear 32, a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com