Relay drying and dust removing device

A dry dust removal and relay technology, applied in the direction of drying gas arrangement, dust removal, drying solid materials, etc., can solve the problems of dust diffuse, harmful to health, poor dust removal effect, etc., to reduce energy consumption, prevent water short circuit, and improve work environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] All features disclosed in this specification, or all disclosed steps in a method or process, may be combined in any way except mutually exclusive features and / or steps.

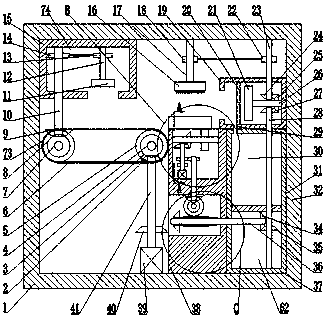

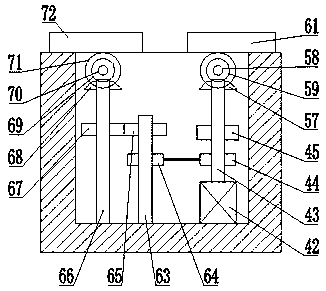

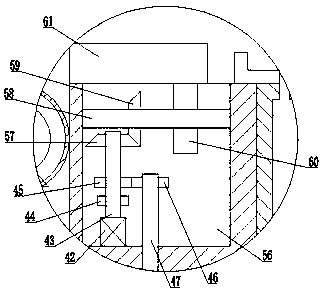

[0016] Combine below Figure 1-4 The present invention is described in detail, for the convenience of description, the orientations mentioned below are now specified as follows: figure 1 The projection relationship of itself is the same as the up, down, left, right, front, and rear directions.

[0017] A relay drying and dust-removing device of the device of the present invention includes a frame 1 , a mobile drying assembly is arranged at the inner bottom end of the frame 1 , and the mobile drying assembly includes a first motor fixedly installed with the bottom end of the frame 1 39. The end of the first motor 39 is powered with a first rotating shaft 41 extending up and down, the upper end of the first rotating shaft 41 is fixedly connected with a first bevel gear 2, and the upper end of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com