Neutron flux tube inspection integrated device

A flux and neutron technology, which is used in the field of integrated hydrostatic test and helium inspection of sub-flux tubes. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

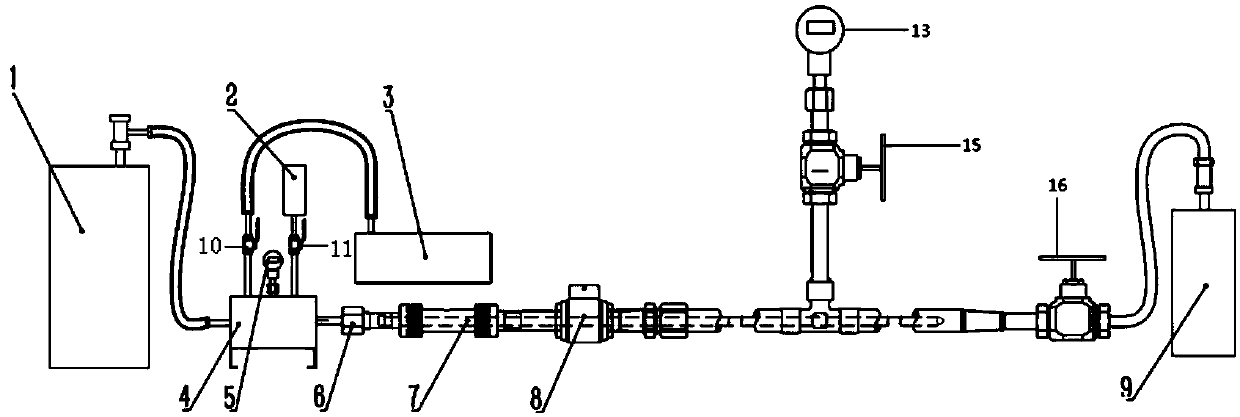

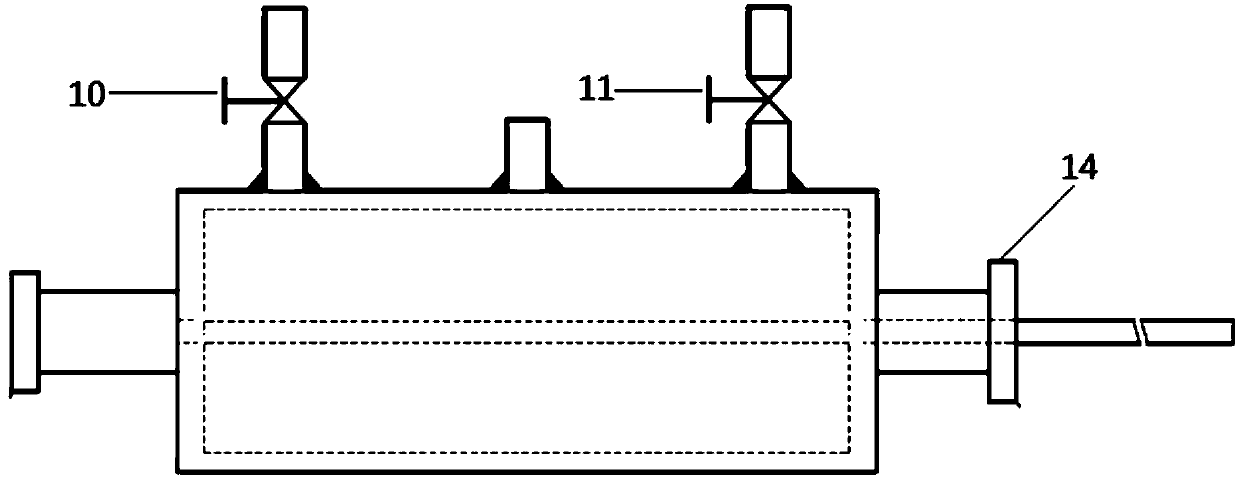

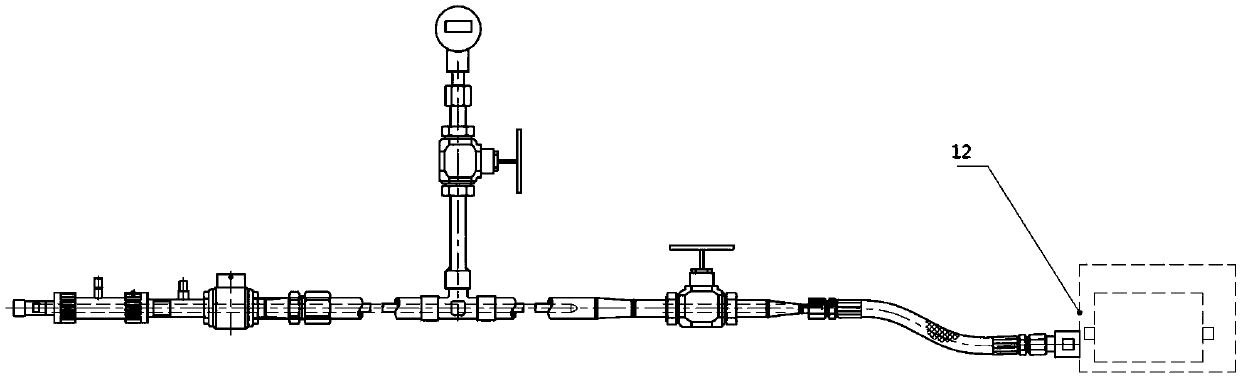

[0024] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0025] like figure 1 , figure 2 , image 3 As shown, a nuclear reactor neutron flux tube overall hydrostatic test and helium inspection integrated device, including: helium leak detector 1, helium leak detection connection device 4, sealing ball valve 8, neutron flux tube outer wall filling Helium device 9, water pressure booster pump 12, pressure gauge 13. The helium leak detector 1 and the helium leak detection connection device 4 are snap-connected by bellows, the neutron flux tube 6 is connected with the helium gas leak detection device 4, the handle end of which is fixed at the sealing section 7 of the middle body, and the middle body The sealing section 7 is connected with the sealing ball valve 8 by bolts; in the state of helium gas leak detection, the helium filling device 9 on the outer wall of the neutron flux tube is connected with the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com