Probe for measuring whole parameters of transonic three-dimensional steady-state flow field

A steady-state flow field and full-parameter technology, which is applied to the measurement of full-parameters of the outlet and interstage transonic three-dimensional steady-state flow field, the inlet of turbomachinery, and the field of probes for measuring the full parameters of the transonic three-dimensional steady-state flow field. Solve the problem that the probe cannot simultaneously measure the total temperature, total pressure, static temperature, static pressure, Mach number, deflection angle, pitch angle, speed, density parameters, temperature probe airflow insensitivity angle is small, temperature sensor Easy to damage and other problems, to achieve the effect of strengthening convective heat transfer, stable temperature recovery coefficient, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

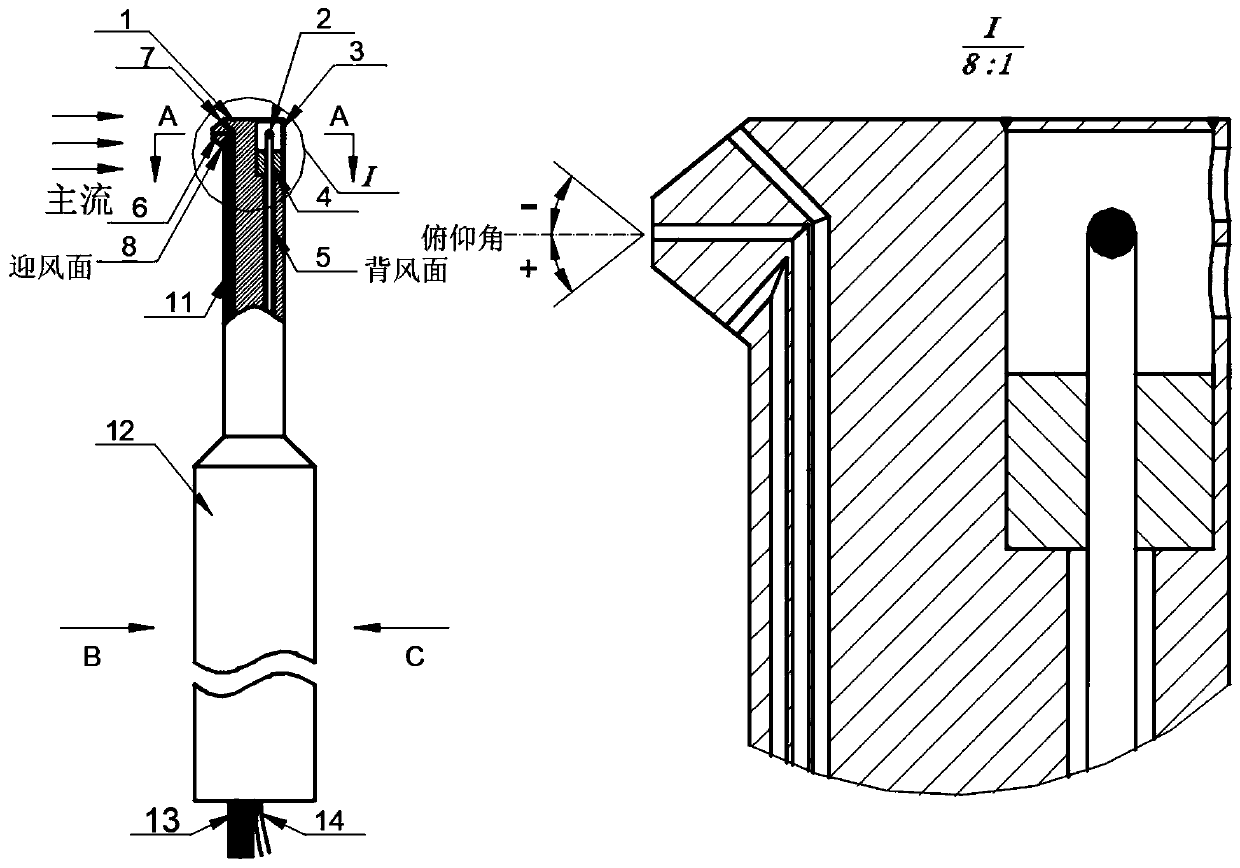

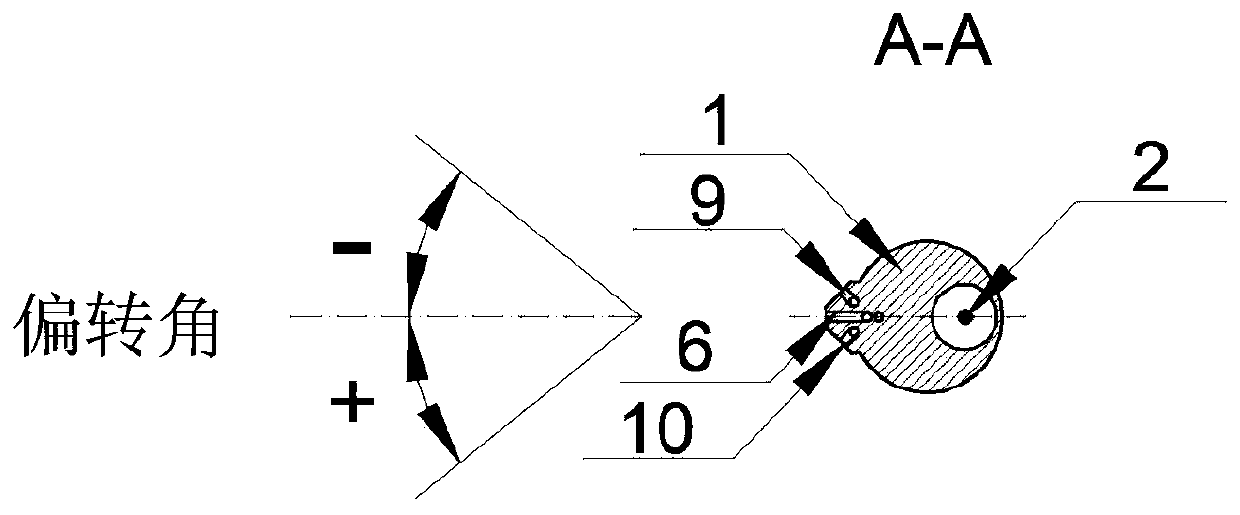

[0033] Such as Figure 1~4 Shown is the schematic diagram of the probe of the present invention applied to interstage measurement of compressors, Figure 5 It is a schematic diagram of the installation of the probe of the present invention for measuring the three-dimensional flow field between compressor stages. A probe for measuring all parameters of a transonic three-dimensional steady-state flow field, consisting of a probe head (1), a temperature sensor (2), a convective heat exchange hole (3), an adiabatic insulating seal (4), and a temperature sensor wire Cable outlet channel (5), middle hole for pressure measurement (6), upper hole for pressure measurement (7), lower hole for pressure measurement (8), left hole for pressure measurement (9), right hole for pressure measurement (10), pressure introduction tube Channel (11), probe rod (12), pressure introduction tube (13) and temperature sensor cable (14), characterized in that: the probe head (1) is cylindrical, and the ...

Embodiment approach

[0055] Such as Figure 6-9 Shown is a schematic diagram of the probe of the present invention applied to measuring the inlet of the compressor, Figure 10 It is a schematic diagram of the installation of the probe of the present invention for measuring the three-dimensional flow field at the inlet of the compressor. A probe for measuring all parameters of a transonic three-dimensional steady-state flow field, consisting of a probe head (1), a temperature sensor (2), a convective heat exchange hole (3), an adiabatic insulating seal (4), and a temperature sensor wire Cable outlet channel (5), middle hole for pressure measurement (6), upper hole for pressure measurement (7), lower hole for pressure measurement (8), left hole for pressure measurement (9), right hole for pressure measurement (10), pressure introduction tube Channel (11), probe rod (12), pressure introduction tube (13) and temperature sensor cable (14), characterized in that: the probe head (1) is cylindrical, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com