Eccentric chain wheel transmission device

An eccentric sprocket and transmission technology, applied in transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of difficulty, low overall structural strength, and high cost, achieving low cost and avoiding high cost , to construct simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

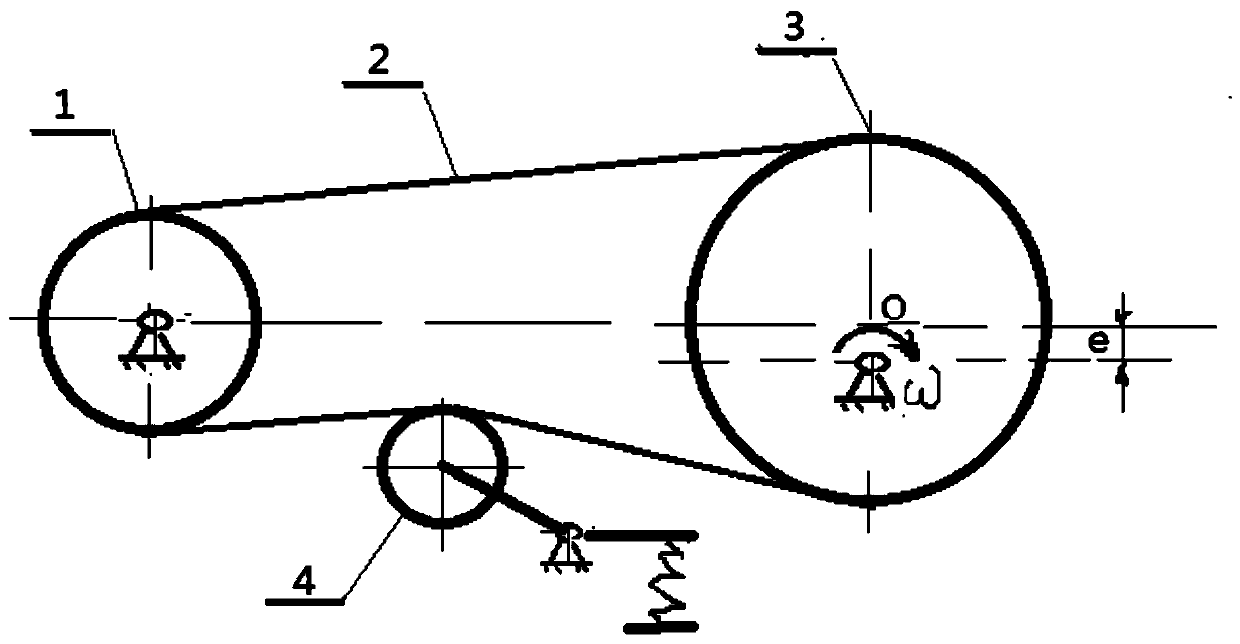

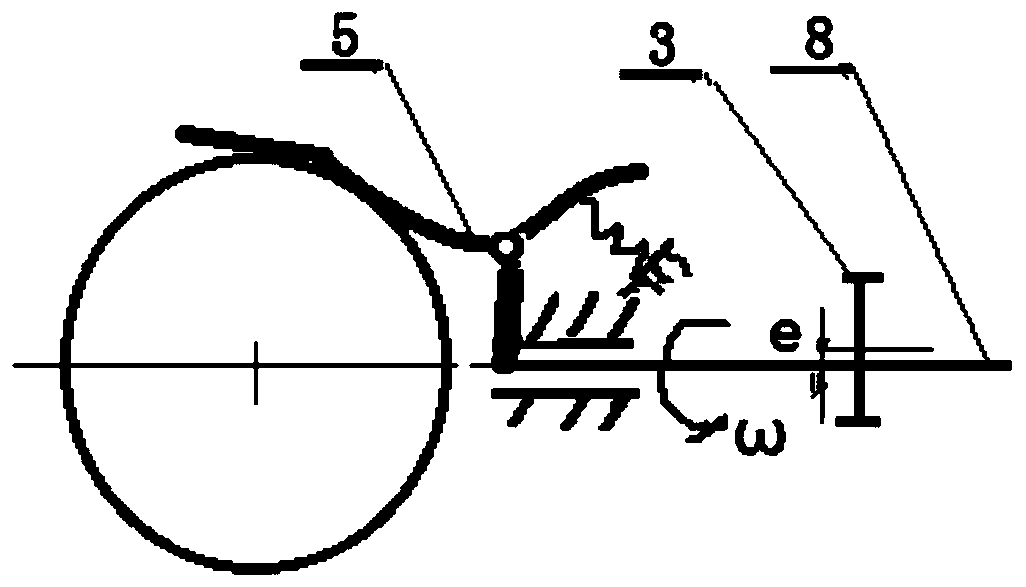

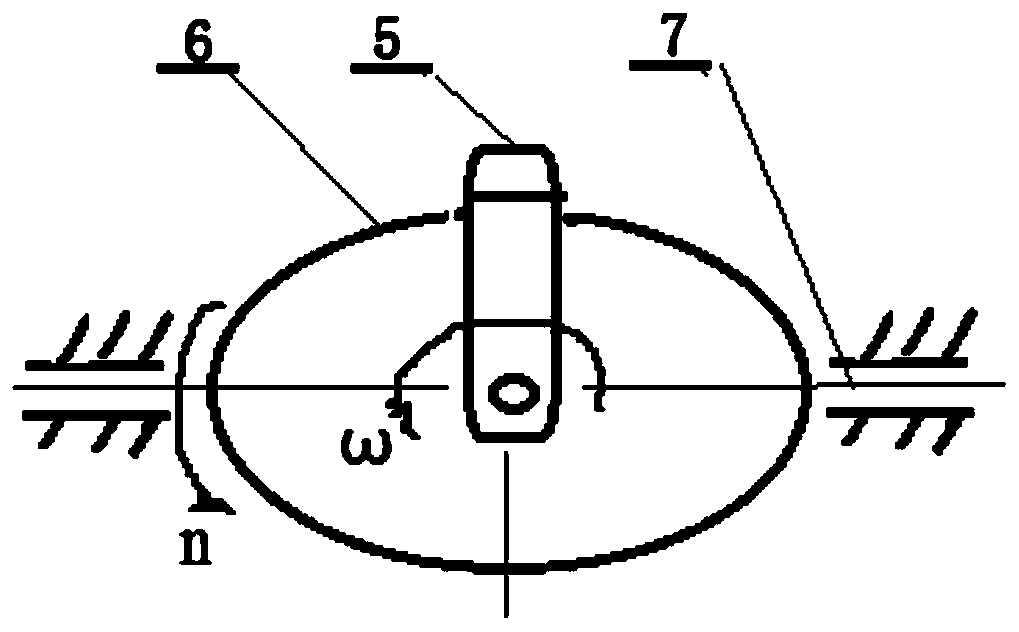

[0034] like figure 1 , Figure 4 , Figure 5 , Image 6 ,as well as Figure 7 A kind of eccentric sprocket transmission device shown, in order to realize chain transmission, comprises chain 2, driving sprocket 1, tensioning pulley 4, and driven sprocket 3 that are sequentially connected through the chain 2; wherein, the The driving sprocket 1 is configured to have a special tooth shape, and is used to provide power to the driven sprocket 3 through the chain 2; the tensioning wheel 4 is configured to have an engaging portion or The fitting friction part is used to adjust the tension of the chain 2; the driven sprocket 3 is configured to have a special tooth shape suitable for the driving sprocket 1 and the chain 2, and is used for according to the The angular velocity of the power output provided by the driving sprocket 1 changes periodically.

[0035] like figure 1 , figure 2 , image 3 ,as well as Figure 7 The e shown in the figure is the eccentricity, ω is the ang...

Embodiment 2

[0039] like figure 1 , Figure 4 , Figure 5 , Image 6 ,as well as Figure 7 The shown eccentric sprocket transmission device, in order to realize chain transmission, includes a chain 2, a driving sprocket 1, a tensioning wheel 4, and a driven sprocket 3 that are sequentially connected through the chain 2; wherein,

[0040] The driving sprocket 1 is configured to have a special tooth shape, and is used to provide power to the driven sprocket 3 through the chain 2;

[0041] The tensioning wheel 4 is configured to have an engaging portion or a fitting friction portion compatible with the chain 2 for adjusting the tension of the chain 2; the preferred solution in this embodiment is that the tensioning wheel 4 has an adjusting part configured to automatically adjust the position of the tensioning wheel 4 according to the tension of the chain 2 in motion, so that the tension of the chain 2 is within a preset range. Specifically, such as Figure 5As shown, the tensioning whee...

Embodiment 3

[0050] like figure 1 , Figure 4 , Figure 5 , Image 6 ,as well as Figure 7 The shown eccentric sprocket transmission device, in order to realize chain transmission, includes a chain 2, a driving sprocket 1, a tensioning wheel 4, and a driven sprocket 3 that are sequentially connected through the chain 2; wherein,

[0051] The driving sprocket 1 is configured to have a special tooth shape, and is used to provide power to the driven sprocket 3 through the chain 2;

[0052] The tensioning wheel 4 is configured to have an engaging portion or a fitting friction portion compatible with the chain 2 for adjusting the tension of the chain 2; the preferred solution in this embodiment is that the tensioning wheel 4 has an adjusting part configured to automatically adjust the position of the tensioning wheel 4 according to the tension of the chain 2 in motion, so that the tension of the chain 2 is within a preset range. Specifically, such as Figure 5 As shown, the tensioning whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com