A range hood with double fans in series

A technology for range hoods and models, which can be used in the removal of range hoods, machines/engines, mechanical equipment, etc., and can solve problems such as performance dissatisfaction, poor sound quality, and unstable sound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

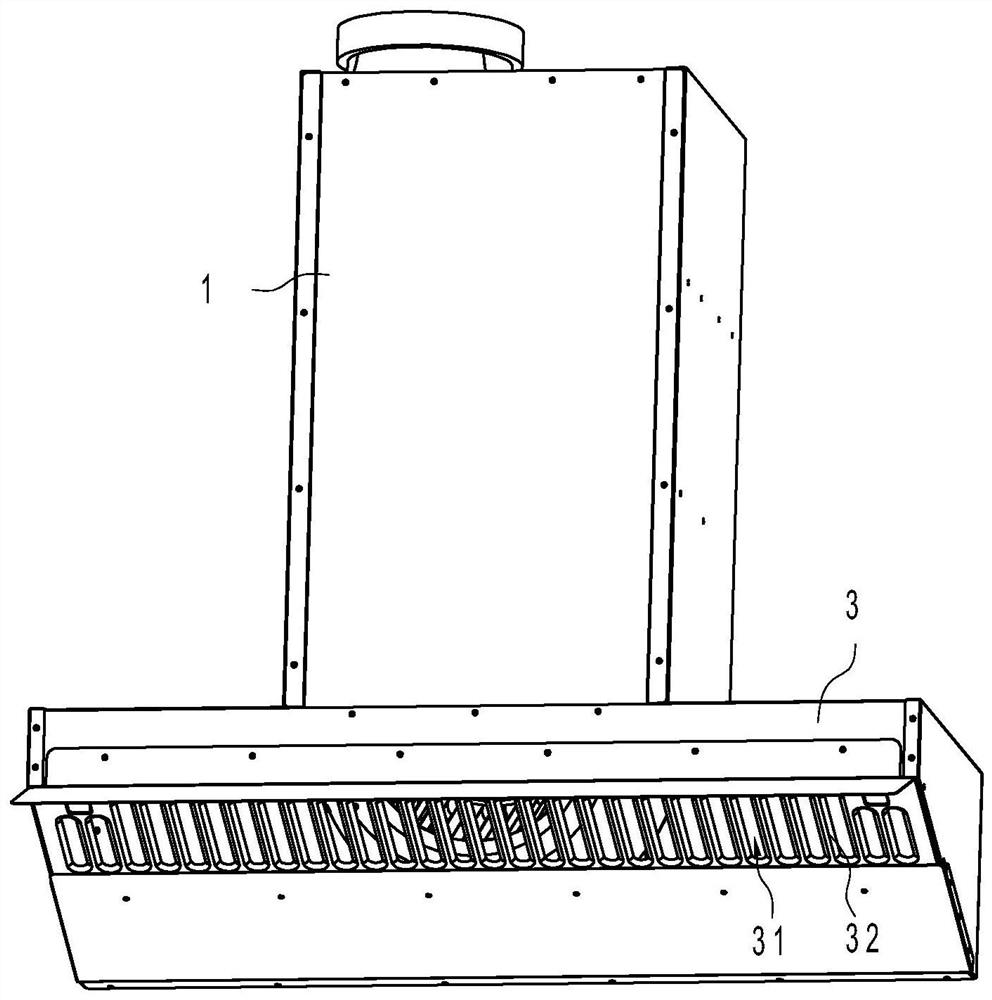

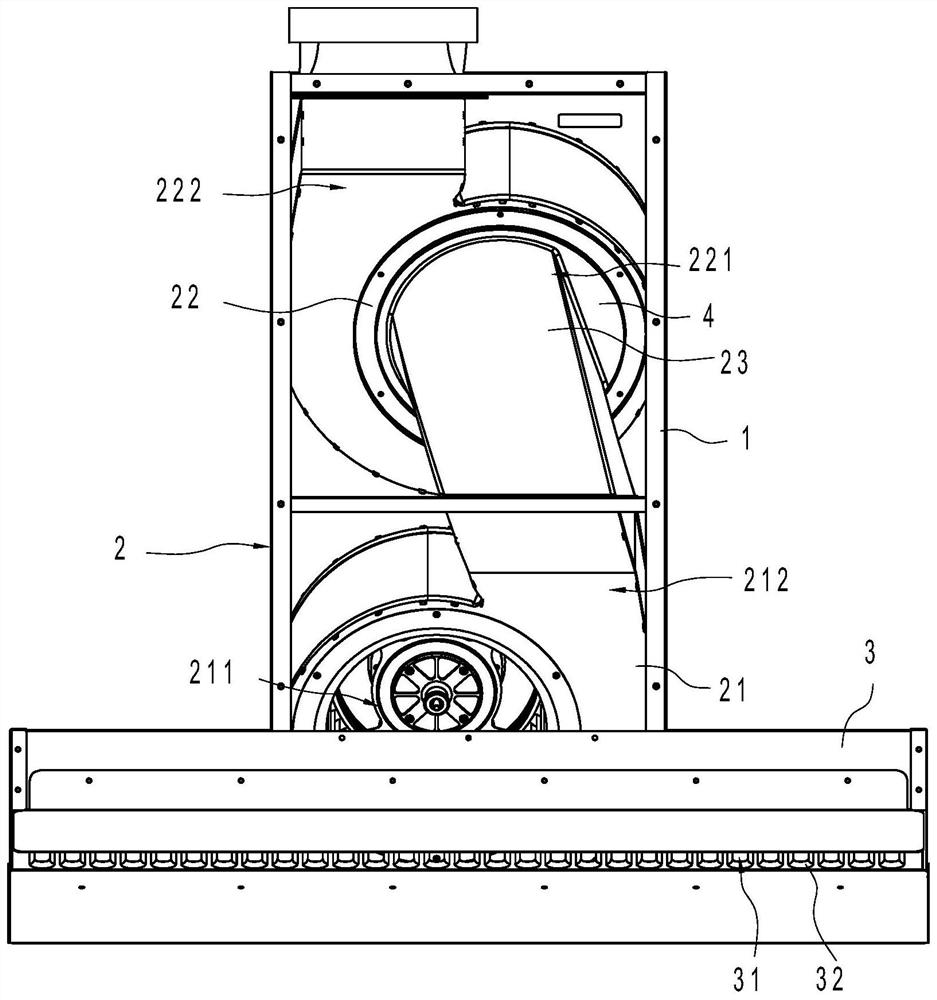

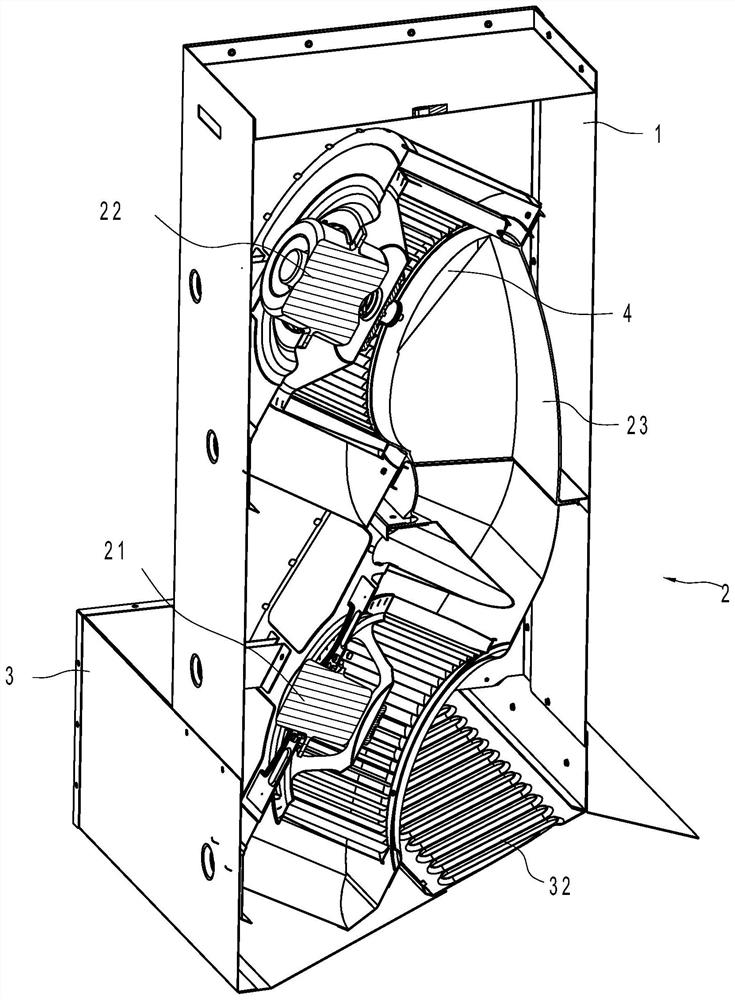

[0031] Such as Figure 1 to Figure 9 As shown, the tandem double-fan range hood in this embodiment includes a smoke collection hood 3 and a fan cover 1 arranged on the smoke collection hood 3 . An air inlet 31 is opened on the above-mentioned smoke collecting hood 3 , and an air inlet grill 32 is arranged on the air inlet 31 . Fan system 2 is arranged in above-mentioned blower casing 1, and this fan system 2 comprises a primary centrifugal fan 21 and a secondary centrifugal fan 22, and this secondary centrifugal fan 22 is arranged on the top of the primary centrifugal fan 21, and this primary centrifugal fan The first air outlet 212 of 21 and the second air inlet 221 of the secondary centrifugal fan 22 are connected through the connecting pipe 23, and the spiral direction of the volute of the primary centrifugal fan 21 and the spiral directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com