A plate shearing machine shearing mechanism

A shearing machine and shearing technology, applied in the direction of shearing device, shearing machine equipment, shearing machine accessories, etc., can solve the problems of large horizontal space occupation and small horizontal space occupation, etc., and achieve weight reduction and convenient use Good, highly automated results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

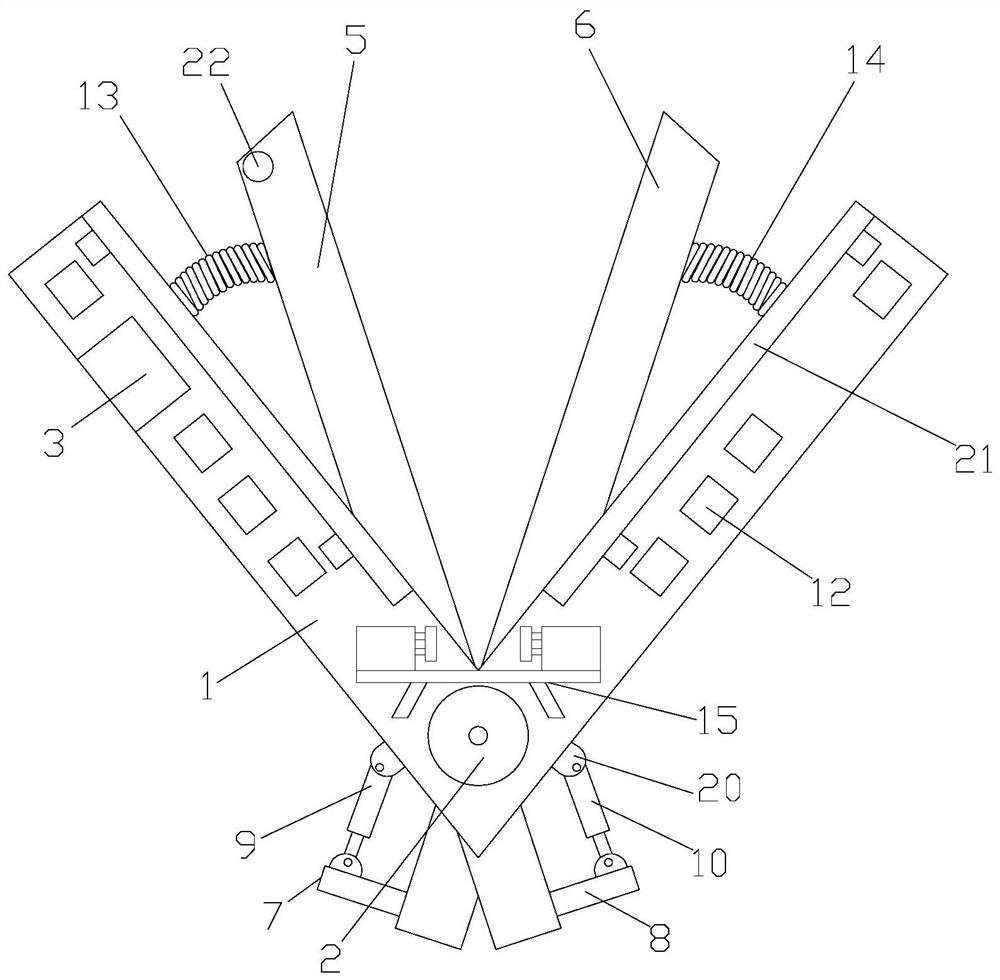

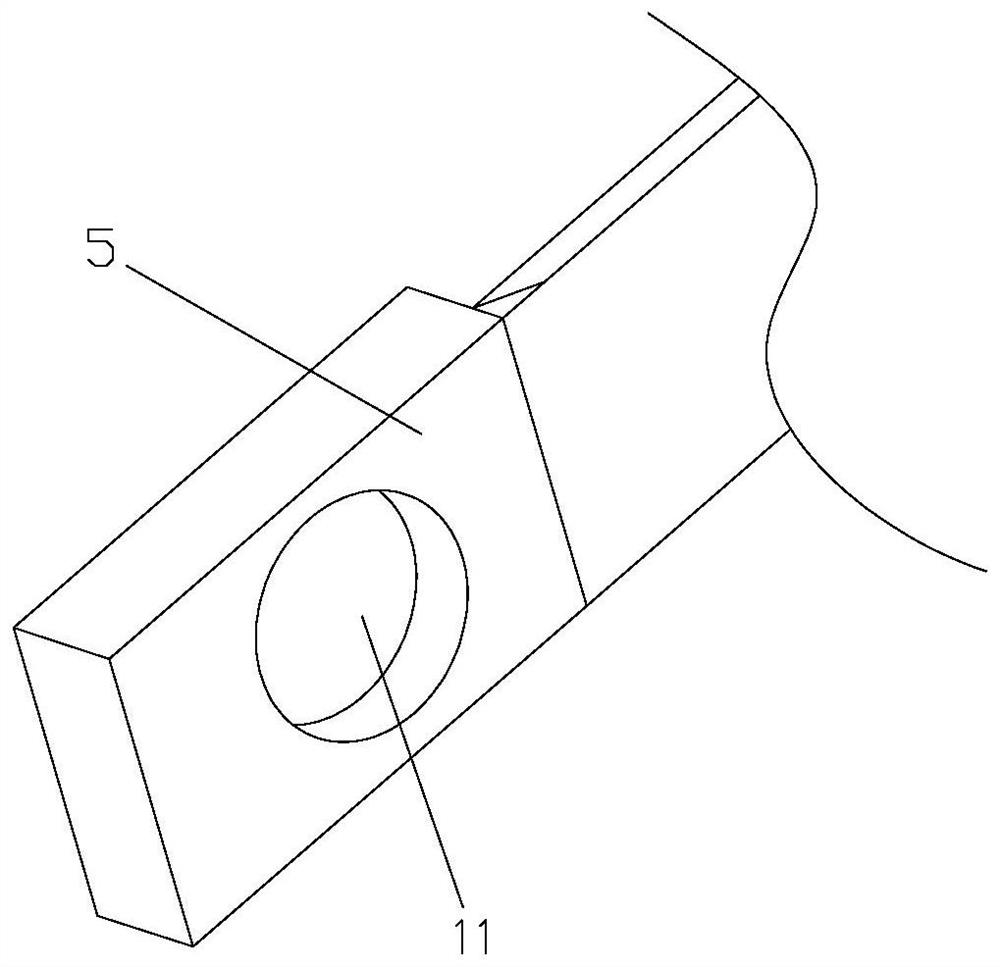

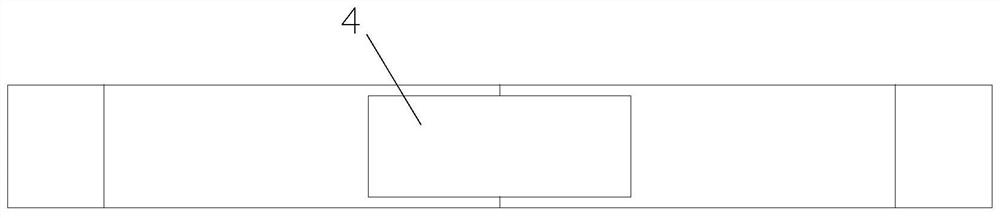

[0027] Such as Figure 1-4As shown, a plate shearing machine shearing mechanism includes a V-shaped support frame 1, a servo motor 2 and a control device 3, the V-shaped support frame 1 is provided with a perforation 4, and the V-shaped support frame 1 is provided with a The first blade 5 and the second blade 6, the ends of the first blade 5 and the second blade 6 pass through the perforation 4, the first blade 5 and the second blade 6 form an X-shaped setting, the first blade 5 and the end of the second blade 6 are respectively provided with a first connecting bar 7 and a second connecting bar 8, and a first electric cylinder 9 is arranged between the first connecting bar 7 and the V-shaped support frame 1, and the first electric cylinder 9 The two ends are respectively connected in rotation with the first connecting bar 7 and the V-shaped support frame 1, and a second electric cylinder 10 is arranged between the second connecting bar 8 and the V-shaped support frame 1, and t...

Embodiment 2

[0030] Such as Figure 1-4 As shown, a plate shearing machine shearing mechanism includes a V-shaped support frame 1, a servo motor 2 and a control device 3, the V-shaped support frame 1 is provided with a perforation 4, and the V-shaped support frame 1 is provided with a The first blade 5 and the second blade 6, the ends of the first blade 5 and the second blade 6 pass through the perforation 4, the first blade 5 and the second blade 6 form an X-shaped setting, the first blade 5 and the end of the second blade 6 are respectively provided with a first connecting bar 7 and a second connecting bar 8, and a first electric cylinder 9 is arranged between the first connecting bar 7 and the V-shaped support frame 1, and the first electric cylinder 9 The two ends are respectively connected in rotation with the first connecting bar 7 and the V-shaped support frame 1, and a second electric cylinder 10 is arranged between the second connecting bar 8 and the V-shaped support frame 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com