Automobile part automatic forging device and forging method

An auto parts and forging technology, applied in metal processing equipment, forging/pressing/hammer devices, forging/pressing/hammering machines, etc., can solve the problems of manual picking and physical damage of workers, and reduce misoperation possibility, simplify the functional structure, and improve the efficiency of automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

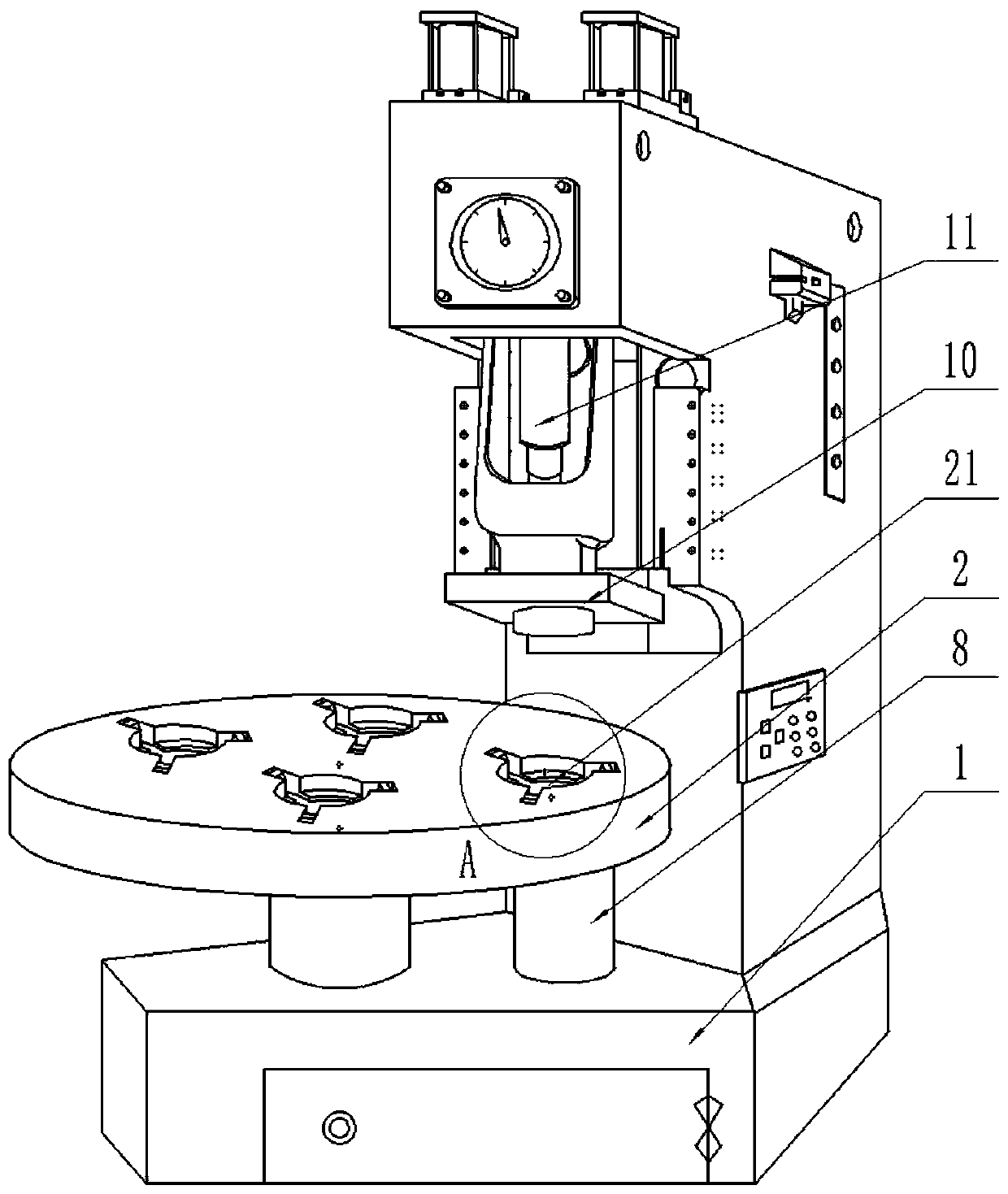

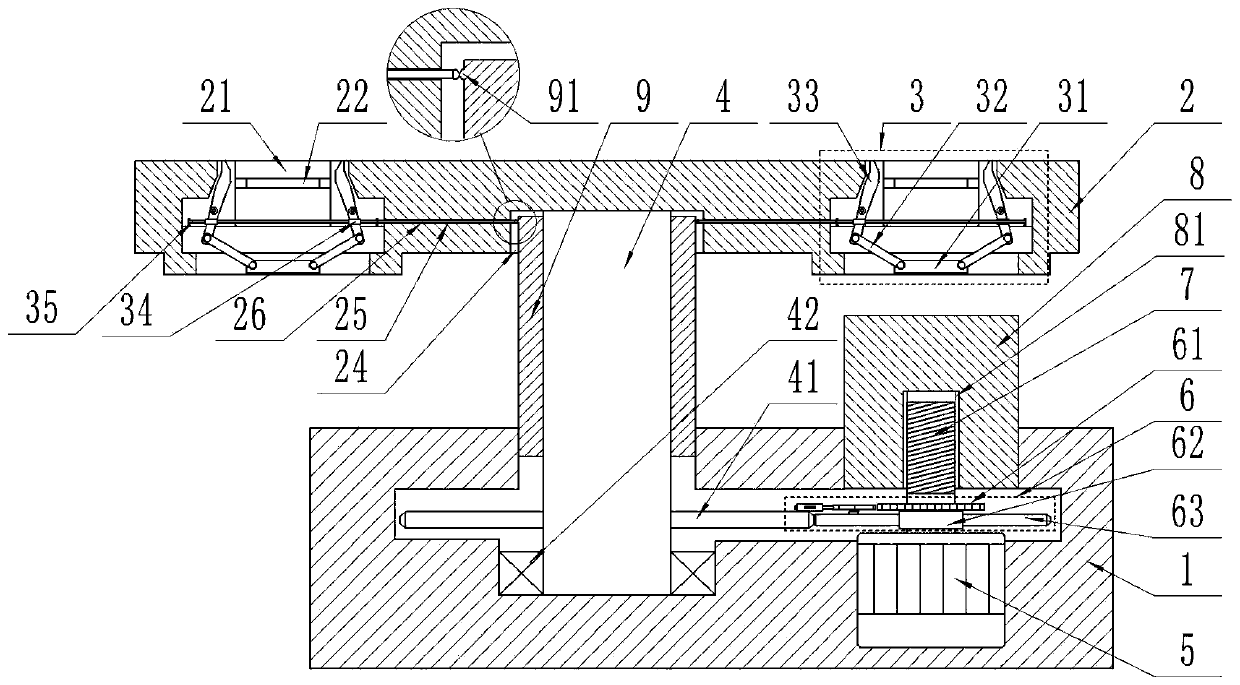

[0066] An automatic forging equipment for auto parts, wherein, such as figure 1 , 2 As shown, it includes: mounting seat 1, forging platform 2, passive clamping mechanism 3, transmission shaft 4, driving device 5, power connecting mechanism 6, stud 7, top pressing part 8, stamping body 10, telescopic device 11.

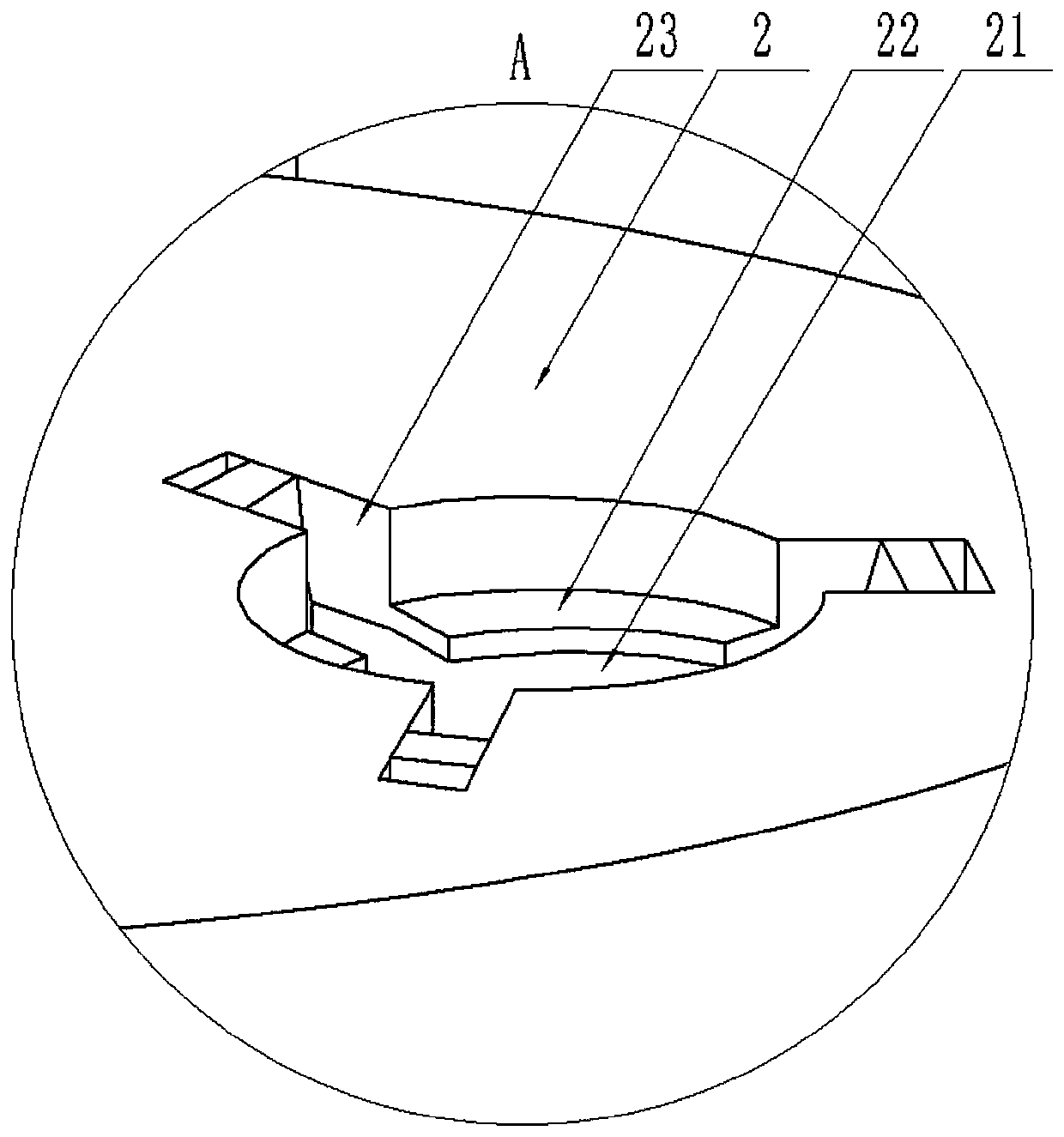

[0067] Such as image 3 As shown, the forging platform 2 is arranged above the installation seat 1 , and the forging platform 2 has: a processing opening 21 , a supporting portion 22 , and a clamping groove 23 .

[0068] The processing port 21 runs through the forging platform 2 . The supporting part 22 is connected to the side wall in the processing opening 21 . The clamping grooves 23 are distributed at the side ends of the processing opening 21 , and the clamping grooves 23 communicate with the processing opening 21 and isolate the supporting portion 22 .

[0069] Such as Figure 4 As shown, the passive clamping mechanism 3 is installed on the forging platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com