Corn fine dried noodles and preparation method thereof

A corn and vermicelli technology, applied in the fields of food science, food preservation, application, etc., can solve the problems of corn flour dough unable to form a network structure, unable to form a viscoelastic dough, unable to exert the edible effect of corn, etc., to achieve rich varieties, Lower cholesterol levels and improve flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

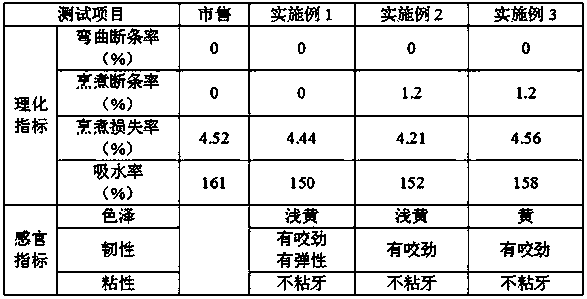

Examples

Embodiment 1

[0025] Take the following raw materials by weight for subsequent use:

[0026] 750 parts of corn flour; 120 parts of flour; 5 parts of table salt; 4 parts of edible alkali; 125 parts of water, 6 parts of bovine plasma protein, 0.4 part of bacterial nanocellulose; 0.2 part of propylene glycol, 3 parts of edible alcohol, and 0.5 part of compound phosphate;

[0027] (1) Corn ripening Crush fresh, plump, mildew-free corn kernels (moisture content 13%) to 80 mesh, add some water, cook at 90-95°C for 15-30 min, and cool to 35-50°C;

[0028] (2) Noodle mixing Add the matured corn and flour into the vacuum noodle mixer and knead the noodles, stir and dissolve salt, bacterial nanocellulose, bovine plasma protein, edible alkali, and compound phosphate into the remaining water, and slowly Pour it into the dough mixer, knead the dough for 5-15 minutes, add edible alcohol and propylene glycol, and continue kneading the dough for 3-5 minutes; the vacuum degree of the vacuum kneading machine...

Embodiment 2

[0034] Take the following raw materials by weight for subsequent use:

[0035] 50 parts of corn flour; 100 parts of flour; 3 parts of table salt; 2 parts of edible alkali; 100 parts of water, 2 parts of bovine plasma protein, 0.2 part of bacterial nanocellulose; 0.1 part of propylene glycol, 2 parts of edible alcohol, and 0.3 part of compound phosphate.

[0036] The preparation process is the same as in Example 1.

Embodiment 3

[0038] Take the following raw materials by weight for subsequent use:

[0039] 100 parts of corn flour; 150 parts of flour; 6 parts of table salt; 5 parts of edible alkali; 150 parts of water, 8 parts of bovine plasma protein, 0.5 part of bacterial nanocellulose;

[0040] The preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com