Field emission cathode and preparation method thereof

A field emission cathode and cathode technology, applied in the field emission field, can solve the problems of low current density and poor emission stability, and achieve the effect of reducing the potential barrier and improving the field emission current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In view of this, the first aspect of the embodiment of the present invention provides a method for preparing a field emission cathode, comprising the following steps:

[0035] S01. Providing a conductive substrate;

[0036] S02. Configure the hexagonal boron nitride nanosheet dispersion, deposit the hexagonal boron nitride nanosheet dispersion on the conductive substrate, form a hexagonal boron nitride nanosheet film after drying, and obtain a film containing hexagonal boron nitride nanosheets the substrate;

[0037] S03. Provide an anode, use the substrate containing the hexagonal boron nitride nanosheet film as a cathode, and ground the cathode; place the cathode and the anode in a vacuum environment, and gradually apply a voltage to the anode Increase the forward voltage until the ignition phenomenon occurs, and obtain the hexagonal boron nitride nanosheet field emission cathode.

[0038] The preparation method of the field emission cathode provided by the embodime...

Embodiment 1

[0066] A method for preparing a field emission cathode, comprising the following steps:

[0067] Provide a conductive substrate;

[0068] Configured in the hexagonal boron nitride nanosheet dispersion, deposit the hexagonal boron nitride nanosheet dispersion on the conductive substrate to prepare the hexagonal boron nitride nanosheet film, and the hexagonal boron nitride nanosheet film in the hexagonal boron nitride nanosheet film Boron nanosheets have a size of 0.1 μm to 10 μm and a thickness of 1 nm to 50 nm;

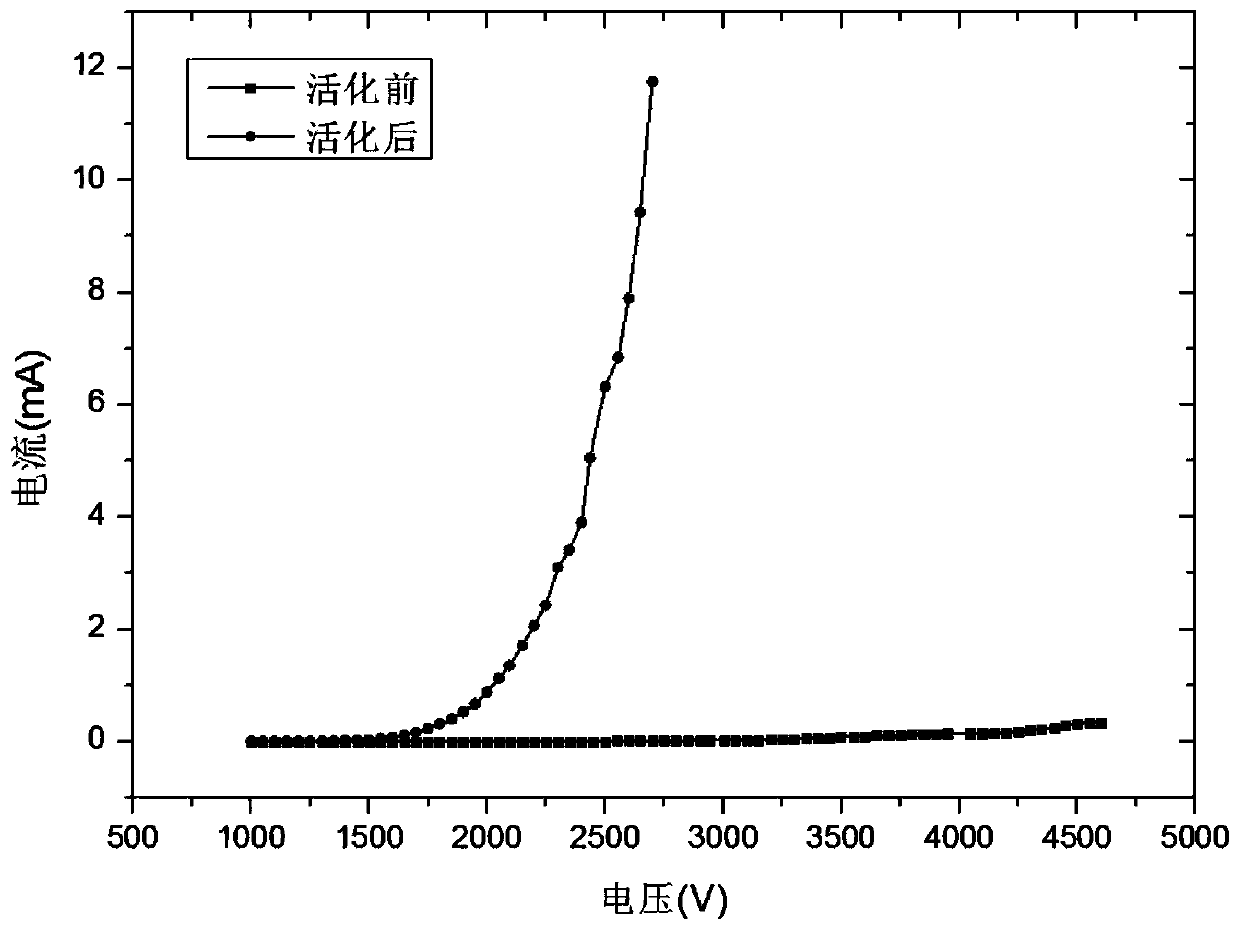

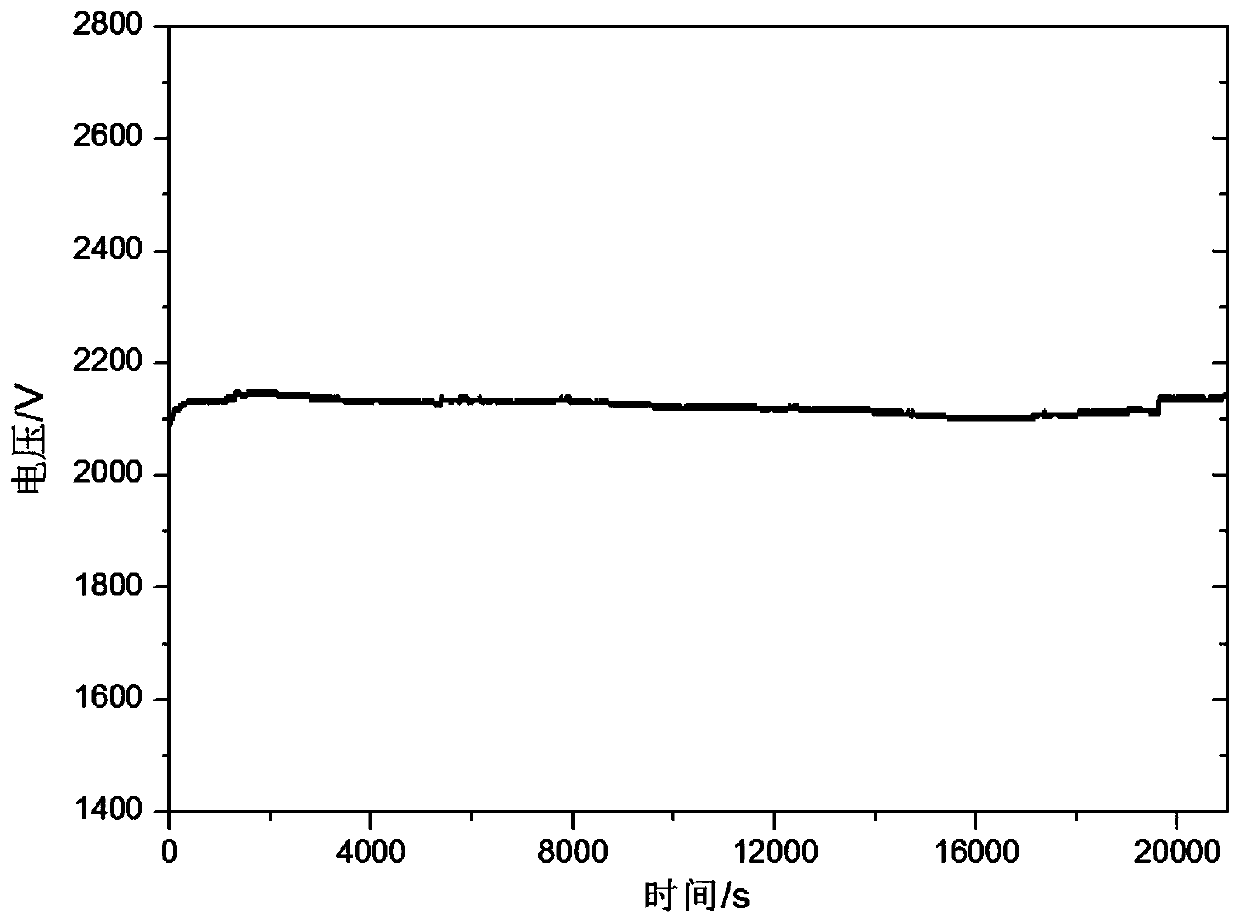

[0069] Provide an anode, use the substrate containing the hexagonal boron nitride nanosheet film as a cathode, set the distance between the cathode and the anode to be 200 μm, and process the cathode as ground; place the cathode and the anode in a vacuum environment , at a vacuum of 1×10 -5 ~1×10 -7 Under certain conditions, a gradually increasing forward voltage is applied to the anode until a sparking phenomenon occurs, and a hexagonal boron nitride nanosheet fie...

Embodiment 2

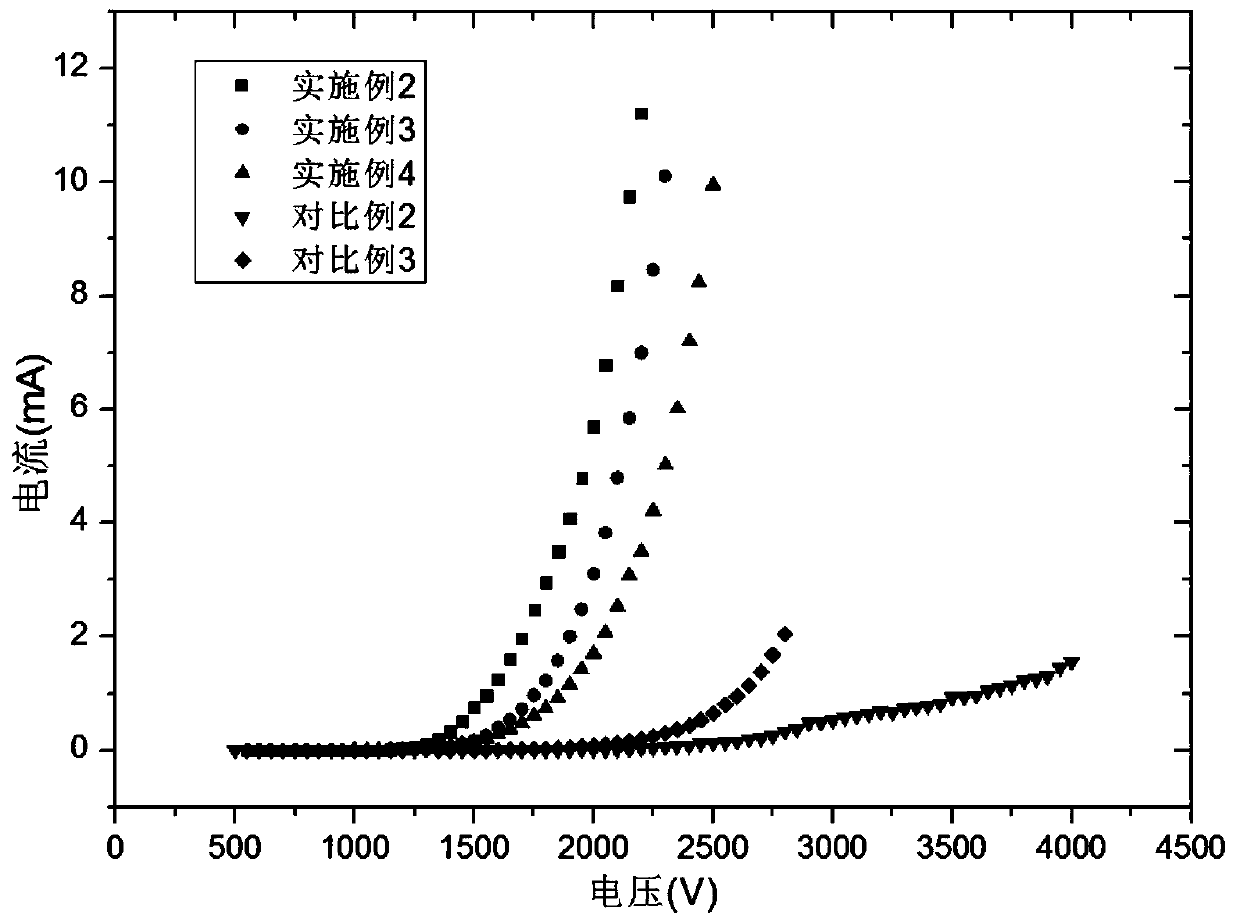

[0076] A method for preparing a field emission cathode, comprising the following steps:

[0077] Provide a conductive substrate;

[0078] Provide the hexagonal boron nitride nanosheet raw material, add the hexagonal boron nitride nanosheet raw material into the solvent, ultrasonically treat it for 24 hours under the condition of ultrasonic power of 200W, and centrifuge to prepare the hexagonal boron nitride nanosheet dispersion. The concentration of the hexagonal boron nitride nanosheet solution may be 1 mg / ml; the hexagonal boron nitride nanosheet dispersion is deposited on the conductive substrate to prepare a hexagonal boron nitride nanosheet film;

[0079] An anode is provided, the substrate containing the hexagonal boron nitride nanosheet film is used as a cathode, and the cathode is grounded; the cathode and the anode are placed in a vacuum environment, and the vacuum degree is 1×10 -5 – 1×10 -7 Under certain conditions, a gradually increasing forward voltage is applie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com